Today, aluminum bronze bearing solutions are an important part of many industrial processes because they work very well in tough situations where other materials often fail. These special parts mix the strength of copper metals with the resistance to rust of aluminum. The result is bearings that work great in harsh conditions, like mines and ships. Knowing the special features and uses of these bearings helps engineers and buying workers make smart choices that improve machine performance and lower the overall cost of ownership.

Understanding Aluminum Bronze Bearings

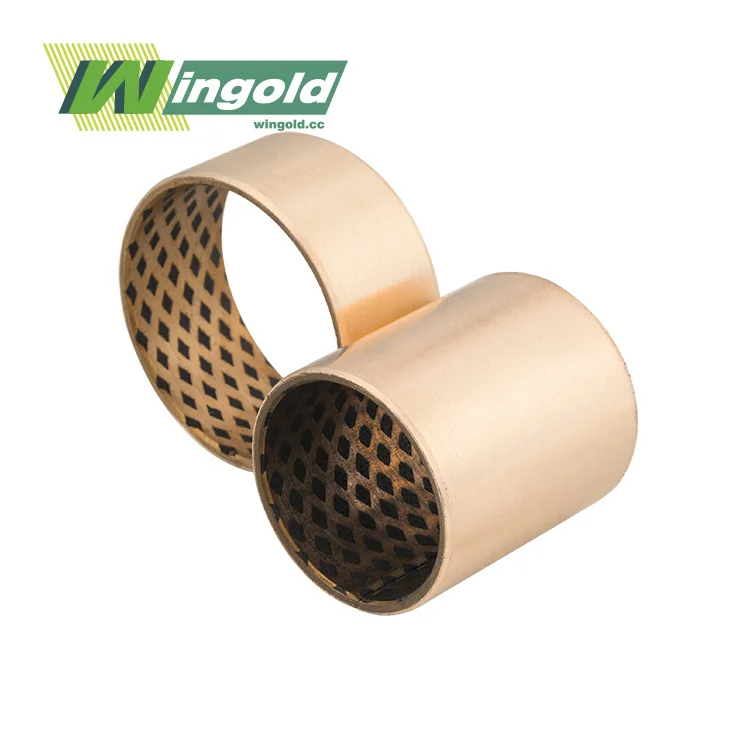

Aluminum bronze bearings are designed parts made from copper-aluminum alloys that have better dynamic qualities than other types of bearing materials. Copper makes up 85–95% of the usual makeup, along with 5–15% aluminum. Iron, manganese, or nickel are often added to improve efficiency.

Material Composition and Metallurgy

Aluminum bronze has a special mechanical structure that makes it a great bearing material that can handle loads of up to 140 MPa and work at temperatures ranging from -40°C to 350°C. The aluminum creates a protective oxide layer that is very resistant to rust, and the copper structure makes sure that the material is very good at conducting heat and resisting wear. When these two things are put together, the friction coefficients are between 0.08 and 0.12, which is much lower than with regular steel bearings.

Key Performance Properties

Aluminum bronze bearings are different from other options because of a number of important characteristics. The material is very good at resisting wear when loaded and unloaded many times, which makes it perfect for uses where the stress levels change. The self-lubricating properties make upkeep easier and increase the service life. These bearings have amazing physical stability across changes in temperature, so they will always work well in places where temperatures are changing.

Industrial Applications of Aluminum Bronze Bearings

Aluminum bronze bearings are essential in many industries because they can be used in a lot of different ways. Because they can work perfectly in harsh situations, they are the best choice for important uses.

Heavy Machinery and Construction Equipment

A lot of the pivot points, swing gears, and hydraulic systems in construction and mining tools depend on aluminum bronze bearings. The high compression strength of these bearings makes them useful for supporting excavators, winch systems, and crane gears. With its very high compression strength, the WGB650-4 reinforced product is perfect for lifting equipment. However, its steel base means it can't be used in places that are likely to rust.

Marine and Offshore Applications

Due to their excellent resistance to rust in salt water, aluminum bronze bearings are widely used in the naval business. These bearings keep ship propeller shafts, rudder sections, and parts of offshore drilling equipment working properly in rough saltwater settings. Galvanic rust doesn't affect this material, which makes it very useful in situations where different metals are used.

Power Generation and Turbomachinery

Aluminum bronze bearings are used in high-temperature, high-speed equipment like steam turbines, water turbines, and other power creation tools. The temperature stability and load capacity make it possible to work reliably in harsh conditions with little break for repair. When used in places where normal materials would fail quickly, these bearings work great.

Comparative Analysis for Informed Decision-Making

When choosing the best bearing material, performance traits, weather conditions, and cost must all be carefully considered. Aluminum bronze bearings have special benefits that make them better choices in some situations.

Performance Comparison with Alternative Materials

Bearings made of aluminum bronze are much stronger and less likely to rust than bearings made of brass. Even though steel bearings are strong, they don't have the anti-corrosion and self-lubricating qualities that aluminum bronze does. Cast iron options can't hold as much weight or keep heat in as well as aluminum bronze in tough situations. Because aluminum bronze bearings are more resistant to wear, they last longer between services and cost less to repair.

Cost-Effectiveness Analysis

Cast brass bushings may cost more at first than some other options, but their longer service life and lower maintenance requirements often result in a lower total cost of ownership. The WGB650-5 product is a great example of cost-effective engineering. It can be used instead of luxury grades in places where performance needs are modest, like mold guide columns and injection molding machine frames, saving material.

Procurement and Supply Chain Insights

Effective procurement of aluminum bronze bearings requires understanding supplier capabilities, quality standards, and delivery timelines. The complexity of these specialized components demands careful supplier selection and relationship management.

Supplier Evaluation Criteria

When looking at possible sources, it's important to make sure they have good manufacturing facilities, full testing capabilities, and ISO certifications. Being able to offer customization choices, expert help, and quick responses for pressing orders has a big effect on how efficiently operations run. Suppliers who have CNC machining centers and centrifugal casting production lines show that they know how to make things well enough to keep the standard high.

Order Planning and Customization

Procurement tactics are affected by things like minimum order amounts, wait times for standard vs. special goods, and price models for large purchases. Custom aluminum bronze bearings may need longer wait times, so it's important to be able to accurately predict demand. When suppliers offer flexible minimum orders, it's easier to keep track of supplies and less expensive to do so.

Wingold Bearing: Your Trusted Aluminum Bronze Bearing Manufacturer

Wingold Bearing is the world's best maker of high-performance aluminum bronze bearings, providing unmatched quality and dependability to industry markets around the world. Our full range of manufacturing services includes choosing the materials, checking them, delivering them, and any other steps in between.

Manufacturing Excellence and Quality Assurance

Our modern production facilities have advanced CNC machine centers and centrifugal casting lines that make sure the quality of all of our products is the same. Full testing labs offer life acceleration analysis and friction coefficient testing, making sure that products meet foreign standards like ISO 4383 and ASTM B22. We keep strict quality control throughout the whole manufacturing process, from making quick prototypes to being able to produce 10,000 tons a year.

Product Range and Customization Capabilities

Wingold's line of aluminum bronze bearings includes both standard sizes and custom options, such as the WGB650-4 for high-compression uses and the WGB650-5 for low-cost options. During the creation process, our engineering team gives one-on-one technical help. This lets us make unique solutions that precisely meet the needs of each application, while also improving production speed, efficiency, flexibility, quality consistency, process reliability, faster delivery times, and overall cost effectiveness for customers.

Conclusion

Aluminum bronze bearings represent an optimal solution for industrial applications demanding exceptional performance under extreme conditions. Their unique combination of high load capacity, corrosion resistance, and thermal stability makes them indispensable across industries from heavy machinery to marine operations. Understanding their properties, applications, and procurement considerations enables engineers and purchasing professionals to make informed decisions that enhance equipment reliability while optimizing operational costs. The versatility of products like WGB650-4 and WGB650-5 demonstrates how proper material selection can address specific performance requirements while managing project budgets effectively.

FAQ

What makes aluminum bronze bearings superior to steel bearings for heavy-load applications?

Aluminum bronze bearings offer superior corrosion resistance, self-lubricating properties, and excellent thermal conductivity compared to steel bearings. They maintain dimensional stability under thermal cycling while providing friction coefficients of 0.08-0.12, significantly lower than steel alternatives.

Can aluminum bronze bearings operate in high-temperature environments?

Yes, aluminum bronze bearings excel in high-temperature applications with operating ranges from -40°C to 350°C. Their thermal stability and resistance to oxidation make them ideal for power generation equipment, turbomachinery, and other high-temperature industrial applications.

What are typical lead times for custom aluminum bronze bearing orders?

Lead times for custom aluminum bronze bearings vary based on complexity and quantity. Standard modifications typically require 2-4 weeks, while completely custom designs may need 6-8 weeks. Wingold Bearing provides accurate timeline estimates during the quotation process to support project planning.

Partner with Wingold for Superior Aluminum Bronze Bearing Solutions

Wingold Bearing delivers exceptional aluminum bronze bearing solutions tailored to your specific industrial requirements. Our comprehensive product range, advanced manufacturing capabilities, and dedicated technical support ensure optimal performance for your critical applications. Whether you need standard bearings or custom-engineered solutions, our team provides expert guidance throughout the selection and procurement process. Contact us at info@wingold.cc to discuss your aluminum bronze bearing supplier requirements and discover how our innovative solutions can enhance your equipment performance while reducing operational costs.

References

1. Davis, J.R. (2001). Copper and Copper Alloys: ASM Specialty Handbook. ASM International Materials Park.

2. Neale, M.J. (1995). The Tribology Handbook: Second Edition. Butterworth-Heinemann Engineering.

3. Budinski, K.G. (2013). Guide to Friction, Wear and Erosion Testing: ASTM Manual Series. ASTM International.

4. Blau, P.J. (2001). The Role and Importance of Friction and Wear Testing: ASTM Special Technical Publication. American Society for Testing and Materials.

5. Peterson, M.B. and Winer, W.O. (1980). Wear Control Handbook. American Society of Mechanical Engineers Press.

6. Hutchings, I.M. (1992). Tribology: Friction and Wear of Engineering Materials. Edward Arnold Publishers.