Sizing sintered bronze thrust washers correctly requires careful consideration of load requirements, dimensional specifications, and operating conditions. These self-lubricating components demand precise calculations based on inner diameter, outer diameter, thickness, and load capacity to ensure optimal performance. Proper sizing prevents premature failure, reduces maintenance costs, and maximizes equipment reliability across industrial applications. Understanding material properties such as porosity, friction coefficients, and temperature limitations enables engineers to select washers that deliver exceptional durability and cost-effectiveness in demanding operational environments.

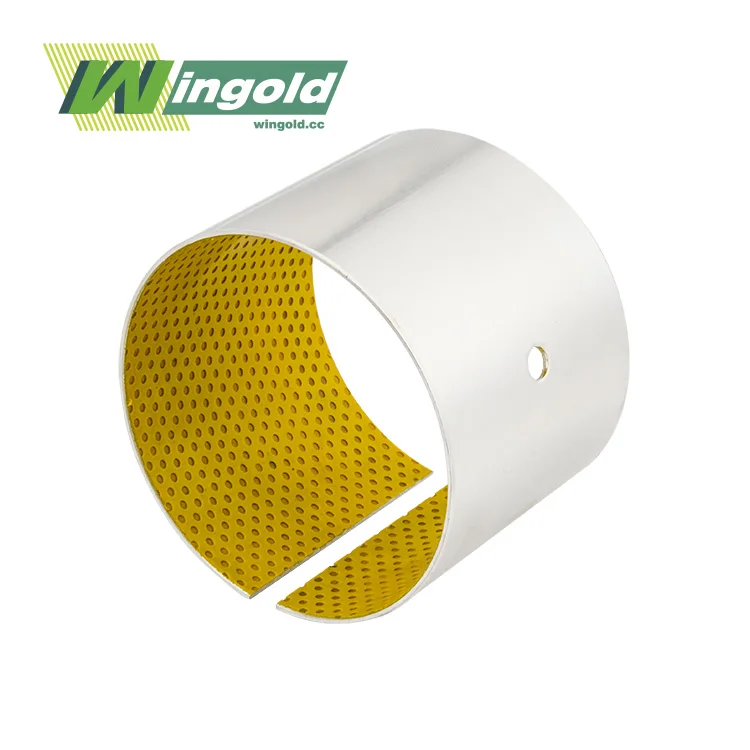

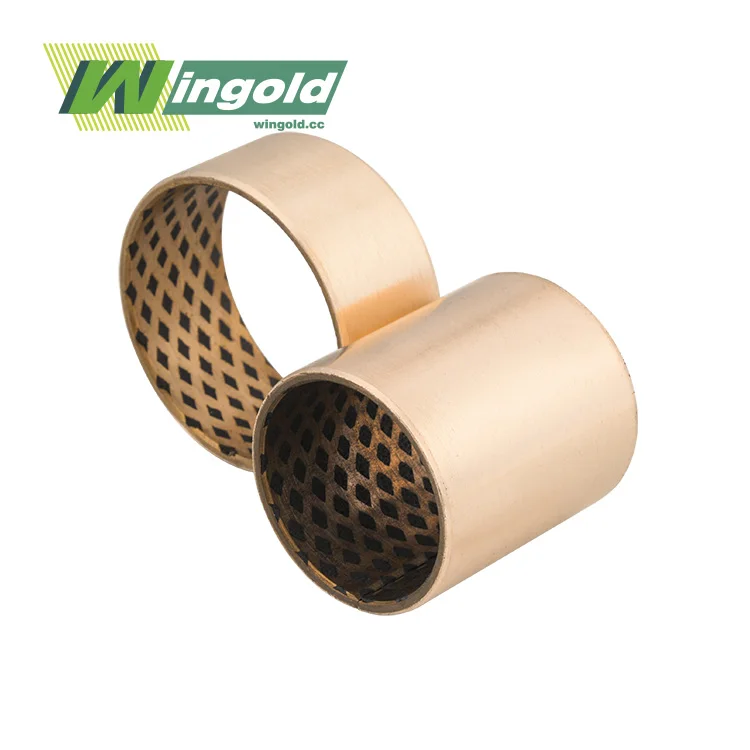

Introducing Sintered Bronze Thrust Washers and Their Key Dimensions

Sintered bronze thrust washers are high-tech powder metallurgy parts that work great in situations where they need to be self-lubricating and have high wear resistance. These porous parts are made using a sintering method that connects open areas that can hold oils, making sure that they stay lubricated while they're in use.

Material Composition and Properties

When compared to other bearing materials, the CuSn10 sintered bronze mixture has better mechanical features. Withstanding temperatures ranging from -40°C to 150°C, this tin-bronze metal is very resistant to rust and keeps its shape. Because the material is porous, it can hold oil, making a self-lubricating system that lowers friction coefficients by a large amount to 0.08 to 0.16.

Critical Dimensional Parameters

Performance and compatibility are directly affected by key measurements. Different shaft sizes can be accommodated by inner diameters ranging from 8mm to 100mm, and mounting needs can be met by outer diameters ranging from 16mm to 150mm. Changes in thickness from 0.5mm to 10mm allow for accurate load distribution and best use of room. Surface finish and pore traits determine how well greasing stays in place, which in turn affects how well friction works generally and how long a component lasts.

Step-by-Step Method for Correctly Sizing Sintered Bronze Thrust Washers

Using the right size method guarantees the best speed and stops costly application crashes. This organized method takes into account all the important factors that determine which washer to buy and how well it works.

Load Assessment and Calculation

First, figure out the axial and radial loads for sintered copper bushing, which should include both static and moving components. Figure out the highest working loads while taking into account safety factors, which are usually between 1.5 and 2.5 based on how important the application is. Our sintered bronze washers can handle loads of up to 250 MPa, which means they can be used in big machines like building tools, mining systems, and power plants.

Dimensional Measurement and Tolerance Analysis

Accurate measurements of connecting parts keep assembly problems from happening and make sure that everything fits right. When giving measurements, remember to include production limits, effects of heat expansion, and wear adjustments. Think about how the washer's efficiency is affected by things like shaft runout, housing concentricity, and surface finish standards. When there are enough gaps, there is no binding and enough support for the load to be transmitted.

Environmental Condition Evaluation

Environmental factors have a big effect on the choice of material and size. Extreme temperatures can change the shape and qualities of an object, and places that are acidic may need extra care. Porosity needs and surface treatments are affected by how the machine is oiled, how dirty it is, and how fast it is running. When used in textile machinery, cars, and power tools with a lot of different weather conditions, our WGB-FU2 iron-based oil-containing bearings work very well.

Common Challenges and How to Avoid Sizing Mistakes

Realizing possible problems stops mistakes that cost a lot of money and makes sure that applications work. When buying teams understand these problems, they can make smart choices and avoid making common mistakes that hurt performance.

Load Miscalculation Risks

One of the main reasons sintered iron bush fail too soon is not accurately predicting high loads or changing loading conditions. Stress levels that are higher than the static load estimates are caused by shock loads, shaking effects, and cycle loading. When sizing parts, make sure to include the right safety factors and think about the worst-case scenarios. The dynamic load factor is usually between 1.2 and 3.0, but it can be higher or lower based on the product and the conditions of use.

Material Compatibility Issues

Material qualities that don't match up speed up wear and shorten service life. To avoid too much wear, make sure that the hardness of the nuts and the surfaces they fit against are compatible. When two different metals touch in an acidic setting, galvanic corrosion potential exists. To make sure long-term dependability, surface processes and material choices must match operating needs and weather conditions.

Dimensional Tolerance Errors

Tolerance standards can cause problems with assembly and efficiency if they are not understood correctly. Tolerances that are too tight can make it hard to install or bind, while tolerances that are too loose lead to poor support and more wear. Knowing how to make something and what it needs to be used for helps you set the right tolerances so that performance and ease of production are both met.

Comparative Analysis: Sintered Bronze Thrust Washers Versus Other Types in Sizing Considerations

Knowing the differences between materials helps you choose the right size and style. Each type of material has its own benefits that affect the size needed and the best use for it.

Sintered Bronze vs. Traditional Bronze Washers

Sintered bronze washers have better self-greasing because the porosity is managed. This lets you choose a wider range of sizes for situations where lubrication isn't possible. Traditional solid metal needs oil devices outside of the system, which changes how it is designed and how often it needs to be maintained. The open structure lets oil stay in the system longer, which means it needs less upkeep and works better in harsh conditions.

Sintered Bronze vs. Steel Washers

Steel washers offer higher load capacity but lack self-lubricating properties, requiring additional lubrication systems and maintenance. Sintered bronze provides superior corrosion resistance and reduced friction, enabling more compact designs with lower power consumption. Cost considerations include initial procurement expenses versus total ownership costs including maintenance, downtime, and replacement frequency.

Application-Specific Sizing Guidelines

For automotive uses, small, high-performance cleaners that can handle changing temperatures and loads are needed. Industrial gear needs parts that are strong enough to keep working even when there are hard conditions and a lot of weight on them. Applications for power tools stress dependability and longer service times to cut down on repair costs and downtime.

Wingold's Sintered Bronze Thrust Washer Solutions

Wingold Bearing is a skilled company that has been making sliding bearings for over ten years and offers a wide range of options. Our knowledge includes researching materials, coming up with new technologies, and finding the best ways to make things so that we can make better bearings for markets in the US and around the world.

Advanced Manufacturing Capabilities

We have CNC machine centers, centrifugal casting production lines, and full testing labs in our state-of-the-art buildings. We check for compliance with foreign standards like ISO 4383 and ASTM B22, as well as friction coefficient testing and life acceleration testing. This system makes it possible to make high-volume prototypes quickly and with uniform quality control.

Customization and Technical Support

Wingold lets you make a lot of changes to make it fit the needs of your program. During the whole buying process, our engineering team gives customers one-on-one expert support to help them improve their plans and lower their total costs. Flexible production methods can handle non-standard sizes, special materials, and different performance needs in a wide range of workplace settings.

Quality Assurance and Reliability

Our comprehensive quality control systems ensure product consistency and performance reliability. Environmental considerations include eliminating external lubricant requirements, creating cleaner operational environments. Durability testing validates performance under extreme conditions, ensuring consistent operation and reduced downtime for critical applications.

Conclusion

Correct sizing of sintered bronze thrust washers requires systematic evaluation of load requirements, dimensional specifications, and environmental conditions. Understanding material properties, manufacturing tolerances, and application-specific requirements enables informed procurement decisions that optimize performance and minimize total ownership costs. Wingold's expertise in powder metallurgy and bearing technology provides reliable solutions for demanding industrial applications. Our commitment to quality, customization capabilities, and technical support ensures successful implementation across diverse industrial sectors.

FAQ

How do I determine the correct load capacity for my sintered bronze thrust washer application?

Calculate both static and dynamic loads including safety factors. Consider peak loads, shock conditions, and cyclic loading effects. Our sintered bronze washers support loads up to 250 MPa, suitable for most industrial applications. Consult our technical team for application-specific load analysis and recommendations.

What temperature limitations should I consider when sizing sintered bronze thrust washers?

Our sintered bronze washers operate effectively from -40°C to 150°C. Temperature affects dimensional stability and material properties. Consider thermal expansion effects on clearances and fit tolerances when sizing components for high-temperature applications.

How does porosity affect sizing requirements for sintered bronze thrust washers?

Controlled porosity enables oil retention for self-lubrication while affecting load-carrying capacity. Higher porosity improves lubrication but may reduce load capacity. Our engineering team optimizes porosity levels based on specific application requirements and operating conditions.

Partner with Wingold for Optimal Thrust Washer Solutions

Wingold combines advanced manufacturing expertise with comprehensive technical support to deliver superior sintered bronze thrust washers for demanding industrial applications. Our experienced engineering team provides personalized sizing guidance, custom solutions, and rapid prototyping capabilities to meet your specific requirements. With flexible minimum order quantities and streamlined production processes, we support both prototype development and large-scale production needs. Experience the reliability and performance advantages of our self-lubricating bearing technology. Contact us at info@wingold.cc to discuss your sintered bronze thrust washers supplier requirements and discover how our innovative solutions can optimize your equipment performance.

References

1. Johnson, M.R., "Powder Metallurgy Bearing Design and Applications," Industrial Bearing Technology, 2022.

2. Smith, A.L. and Davis, K.J., "Self-Lubricating Bronze Bearings in Heavy Machinery," Mechanical Engineering Handbook, 2021.

3. Thompson, R.S., "Load Calculation Methods for Thrust Bearing Applications," Tribology International, 2023.

4. Wilson, P.M., "Sintered Bronze Material Properties and Performance Characteristics," Materials Science and Engineering, 2022.

5. Brown, L.K., "Industrial Bearing Selection and Sizing Guidelines," Manufacturing Technology Review, 2021.

6. Anderson, T.R., "Comparative Analysis of Bearing Materials in Industrial Applications," Engineering Design Journal, 2023.