- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

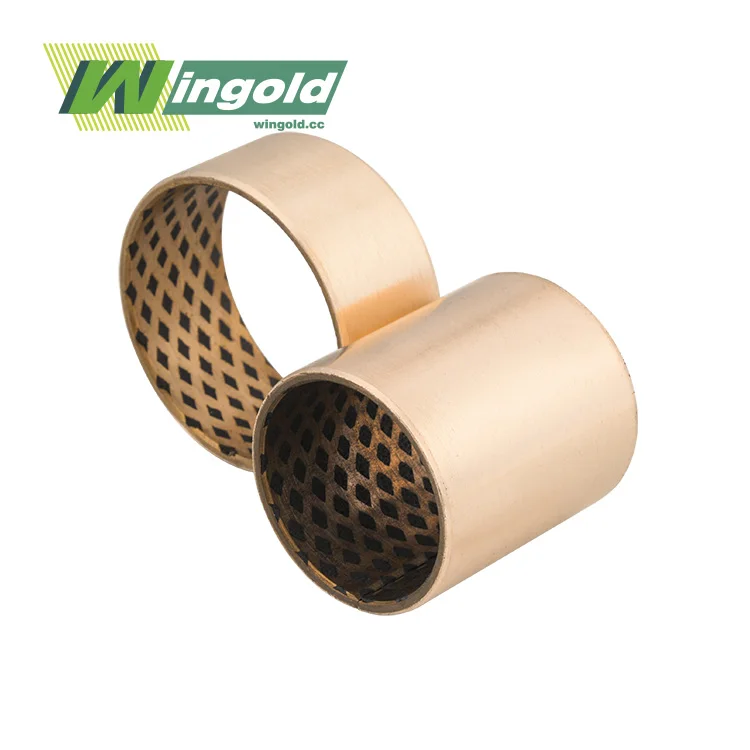

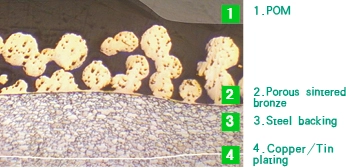

Composite Sleeve Bearing

1.Steel back --sintered porous bronze powder- modified polyformaldehyde (POM)

2.With oil identations

Max load pressure: 70N/mm²

Friction Coef. μ: 0.05-0.25

Applicable temperature : -40℃-130℃

Max allowable PV value dry: 22N/mm²·m/s

Max sliding speed: 2.5m/s

Composite Sleeve Bearings: Innovative Solutions for Industrial Applications

Jiashan Wingold Bearing Co., Ltd. is a leading manufacturer and supplier of high-quality composite sleeve bearings. Our expertise in sliding bearing solutions, coupled with our commitment to innovation, positions us as a top choice for businesses seeking reliable and efficient bearing products. At Wingold, we pride ourselves on delivering products that offer superior performance, durability, and cost-effectiveness for a wide range of industrial applications.

Product Description:

Our products are meticulously engineered to deliver outstanding performance within exacting environments. These bearings integrate the robustness of a metal substrate with a low - friction composite coating, presenting a distinctive combination of durability and seamless operation. The self - lubricating attributes of our composite bearings guarantee a reduction in maintenance demands and an elongation of the service lifespan, rendering them a highly suitable option for diverse industrial applications.

Specifications:

| Property | Value |

|---|---|

| Inner Diameter | 10mm - 500mm |

| Wall Thickness | 1mm - 50mm |

| Length | 10mm - 1000mm |

| Operating Temperature | -40°C to +280°C |

| Load Capacity | Up to 140 MPa |

| Friction Coefficient | 0.02 - 0.25 |

Why Choose Us?

- Over 20 years of industry experience

- State-of-the-art manufacturing facilities

- Customization capabilities to meet specific requirements

- Rigorous quality control processes

- Competitive pricing and flexible solutions

- Global distribution network

- Dedicated technical support team

Material:

Our products are manufactured using a carefully selected combination of materials. The metal backing, typically made of steel or bronze, provides structural integrity and heat dissipation. The composite lining, which may include PTFE, POM, or other advanced polymers, offers excellent tribological properties, ensuring low friction and high wear resistance.

Product Advantages:

Wingold's composite sleeve bearings offer numerous benefits that set them apart in the industry. Their self-lubricating nature eliminates the need for continuous lubrication, reducing maintenance costs and downtime. The composite material's low friction coefficient results in smoother operation and energy savings. These bearings also boast excellent chemical resistance, making them suitable for use in corrosive environments.

One of the key advantages of our products is their ability to absorb vibrations and reduce noise, contributing to improved equipment performance and longevity. The dimensional stability of these bearings ensures consistent operation across a wide temperature range, making them versatile for various applications. Additionally, their lightweight design contributes to overall system efficiency and ease of installation.

Application Areas:

- Automotive Industry: Suspension systems, steering mechanisms, and pedal assemblies

- Aerospace: Landing gear components and flight control systems

- Agricultural Equipment: Pivot points, hinges, and linkages

- Construction Machinery: Excavator arms, loader buckets, and articulated joints

- Material Handling: Conveyor systems, rollers, and guide rails

- Renewable Energy: Wind turbine pitch and yaw systems

- Marine Applications: Rudder bearings, propeller shaft bearings, and deck equipment

- Packaging Machinery: Filling and sealing equipment

- Textile Industry: Spinning and weaving machinery components

Quality Control:

Factory related:

Packaging and Transportation:

Shipping Samples:

Qualification Certification:

Production process related:

Exhibitions:

FAQ:

-

What is the typical lead time for custom orders?

Our standard lead time for custom orders is 2-4 weeks, depending on the complexity and quantity.

-

Can your Composite Sleeve Bearing operate in high-temperature environments?

Yes, our bearings can withstand temperatures up to 280°C, making them suitable for various high-temperature applications.

-

Do you offer technical support for product selection and implementation?

Absolutely! Our team of engineers is available to assist you in choosing the right bearing for your specific application and provide guidance on implementation.

-

Are your products environmentally friendly?

Yes, our bearings are designed with sustainability in mind, offering long service life and reduced energy consumption.

-

Can you provide material certifications and test reports?

Certainly! We provide comprehensive documentation, including material certifications and test reports, upon request.

Contact Us:

For more information about our composite sleeve bearings or to discuss your specific requirements, please contact us at info@wingold.cc. Our team is ready to assist you in finding the perfect bearing solution for your needs.

Learn about our latest products and discounts through SMS or email