- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

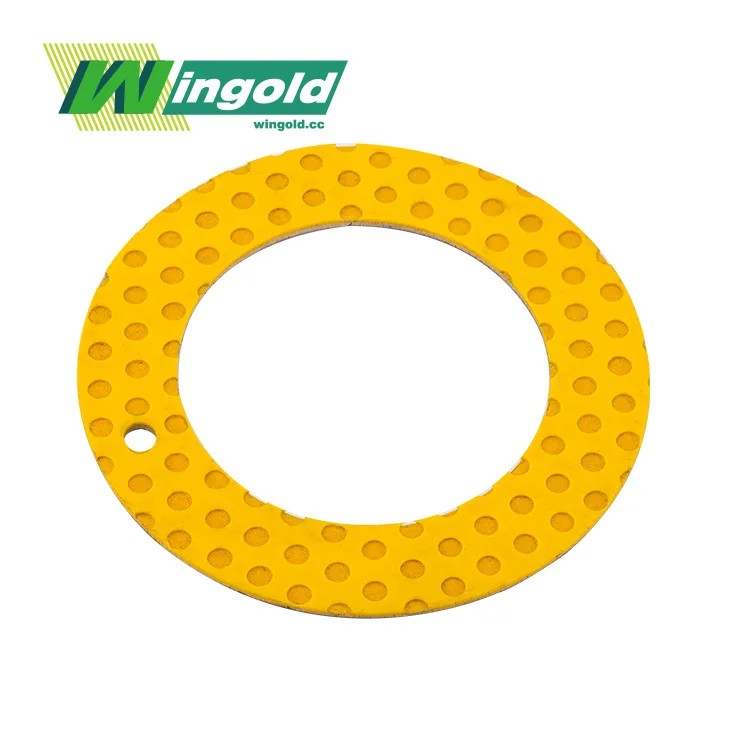

Self Greasing Bearings

Revolutionize Your Machinery with Self Greasing Bearings from Jiashan Wingold

Jiashan Wingold Bearing Co., Ltd. is your premier self greasing bearings manufacturer and supplier. Our innovative products offer unparalleled performance, reliability, and cost-effectiveness. With years of expertise in sliding bearing solutions, we pride ourselves on delivering top-quality products that significantly reduce maintenance needs and extend machinery lifespan.

Product Description

Our state-of-the-art products are engineered to meet the demanding needs of modern industrial applications. These bearings incorporate an innovative self-lubricating system that continuously distributes lubricant during operation, ensuring optimal performance and longevity. By eliminating the need for manual greasing, our bearings significantly reduce maintenance costs and downtime, making them an ideal choice for various industries.

The self greasing mechanism works through a specially designed polymer matrix that slowly releases lubricant over time. This ensures consistent lubrication throughout the bearing's lifespan, even in challenging environments where traditional greasing methods may fail. Our bearings are designed to operate smoothly in a wide range of temperatures and conditions, making them versatile for numerous applications.

Specifications

| Parameter | Value |

|---|---|

| Material | High-grade steel with polymer lubricating matrix |

| Size Range | 20mm - 500mm (inner diameter) |

| Load Capacity | Up to 500 kN (dynamic) |

| Temperature Range | -40°C to 150°C |

| Lubrication | Self-lubricating polymer system |

| Lifespan | Up to 5 times longer than standard bearings |

Why Choose Us?

- Industry-leading expertise in sliding bearing technology

- Customized solutions to meet specific application needs

- Rigorous quality control and adherence to international standards

- Competitive pricing and excellent value for money

- Global distribution network ensuring quick delivery

- Comprehensive technical support and after-sales service

- Commitment to innovation and continuous improvement

Material

Our self greasing bearings are crafted from high-grade steel, ensuring excellent durability and load-bearing capacity. The self-lubricating element consists of a specially formulated polymer matrix that contains and gradually releases the lubricant. This innovative combination of materials results in a bearing that's not only long-lasting but also environmentally friendly, as it reduces the need for additional lubrication and minimizes waste.

Product Advantages

- Maintenance-Free Operation: Our products eliminate the need for regular lubrication, significantly reducing maintenance costs and downtime. This feature is particularly beneficial in hard-to-reach or hazardous locations where manual greasing is difficult or dangerous.

- Extended Lifespan: The continuous, controlled release of lubricant ensures that the bearing remains properly lubricated throughout its life, dramatically extending its operational lifespan compared to conventional bearings.

- Improved Performance: The consistent lubrication provided by our products results in smoother operation, reduced friction, and lower operating temperatures. This leads to improved overall performance and energy efficiency of your machinery.

- Versatility: Our products are designed to perform excellently in a wide range of environments, including high temperatures, dusty conditions, and even underwater applications. This versatility makes them suitable for various industries and applications.

- Cost-Effective: While the initial investment might be higher than traditional bearings, the long-term savings in maintenance costs, reduced downtime, and extended machinery life make our products a highly cost-effective solution.

Application Areas

- Heavy Machinery: Construction equipment, mining machinery, and agricultural implements

- Automotive Industry: Suspension systems, steering mechanisms, and chassis components

- Aerospace: Landing gear, flight control surfaces, and cargo loading systems

- Marine Applications: Propeller shafts, rudder bearings, and offshore equipment

- Food Processing: Conveyor systems, mixers, and packaging machinery

- Textile Industry: Spinning machines, looms, and finishing equipment

- Paper Mills: Rollers, pumps, and drying cylinders

- Wind Turbines: Main shaft bearings, pitch and yaw systems

- Material Handling: Cranes, elevators, and conveyor systems

- Steel Mills: Rolling mill equipment, continuous casting machines

Quality Control:

We implement rigorous quality control measures throughout our production process.

Factory related:

Provide suitable bearing products and supporting services according to the needs of different customers

Packaging and Transportation:

We ensure secure packaging and reliable shipping for all orders.

Shipping Samples:

Sample orders are available for testing and evaluation.

Qualification Certification:

We hold ISO 9001 certification for quality management.

Production process related:

Select appropriate raw materials to produce bearing products that meet technical requirements

Exhibitions:

We regularly participate in international trade shows to showcase our products.

FAQ

Q: How long do self greasing bearings last?

A: Our products typically last up to 5 times longer than standard bearings, depending on the application and operating conditions.

Q: Can products be used in high-temperature environments?

A: Yes, our bearings are designed to operate effectively in temperatures ranging from -40°C to 150°C.

Q: Are custom sizes available?

A: Absolutely! We offer customization to meet your specific requirements. Contact our team for more information.

Contact Us

Ready to optimize your machinery with our innovative self greasing bearings? Contact us today at info@wingold.cc for expert advice and personalized solutions. Let Jiashan Wingold Bearing Co., Ltd. be your partner in enhancing efficiency and reducing maintenance costs.

Learn about our latest products and discounts through SMS or email