- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Cupb10Sn10 Bimetallic Bearing

CuPb10Sn10 Bimetallic Bearing: High-Performance Sliding Solutions

Jiashan Wingold Bearing Co., Ltd. is a leading CuPb10Sn10 Bimetallic bearing manufacturer and supplier. Our expertise in sliding bearing solutions, coupled with advanced manufacturing techniques, ensures superior quality and reliability. Wingold's products offer exceptional load capacity, wear resistance, and longevity, making them the ideal choice for demanding industrial applications.

Product Description:

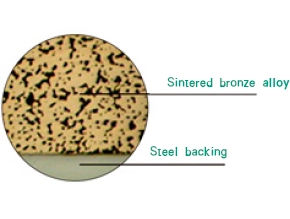

Our products are engineered to excel in high-load, low-speed applications where reliability is paramount. These bearings feature a steel backing with a copper-lead-tin alloy lining, combining strength with excellent tribological properties. The unique composition of 80% copper, 10% lead, and 10% tin creates a self-lubricating surface that minimizes friction and wear, even under challenging operating conditions.

The bimetallic structure of our CuPb10Sn10 bearings provides an optimal balance of load-bearing capacity and conformability. The steel backing offers structural integrity and heat dissipation, while the CuPb10Sn10 lining ensures smooth operation and extended service life. These bearings are designed to withstand heavy radial and axial loads, making them suitable for a wide range of industrial machinery and equipment.

Specifications:

| Parameter | Value |

|---|---|

| Material | CuPb10Sn10 (Copper-Lead-Tin alloy) |

| Backing | Steel |

| Inner Diameter | 20-500 mm |

| Wall Thickness | 1-10 mm |

| Length | Up to 1000 mm |

| Operating Temperature | -40°C to 150°C |

| Maximum Load Capacity | Up to 140 MPa |

| Hardness (HB) | 50-65 |

Why Choose Us?

- Over 20 years of industry experience in sliding bearing solutions

- State-of-the-art manufacturing facilities ensuring consistent quality

- Customization capabilities to meet specific application requirements

- Comprehensive technical support and engineering expertise

- Rigorous quality control processes and certifications

- Competitive pricing and flexible ordering options

- Global shipping capabilities with reliable delivery schedules

- Commitment to innovation and continuous improvement

Material:

Our CuPb10Sn10 Bimetallic bearings are composed of a carefully engineered alloy featuring:

- 80% Copper: Provides excellent thermal conductivity and corrosion resistance

- 10% Lead: Enhances self-lubrication properties and conformability

- 10% Tin: Improves strength and wear resistance

Product Advantages:

The products offer a unique combination of properties that make them ideal for demanding industrial applications:

- Superior Load Capacity: The steel backing and copper-lead-tin alloy work synergistically to support heavy loads, both radial and axial, without deformation.

- Excellent Wear Resistance: The self-lubricating properties of the CuPb10Sn10 alloy significantly reduce wear, even in boundary lubrication conditions, extending the bearing's service life.

- Enhanced Thermal Management: The copper content ensures efficient heat dissipation, maintaining optimal operating temperatures and preventing premature failure.

- Corrosion Resistance: The alloy composition provides good resistance to corrosive environments, making these bearings suitable for various industrial settings.

- Low Friction Performance: The inherent lubricity of the lead component reduces friction, improving energy efficiency and reducing power consumption in machinery.

- Conformability: The soft alloy lining can conform to minor misalignments or shaft irregularities, ensuring even load distribution and smooth operation.

- Cost-Effectiveness: The long service life and minimal maintenance requirements of the products translate to lower total cost of ownership for end-users.

Application Areas:

- Heavy Construction Equipment: Excavators, bulldozers, and cranes

- Mining Machinery: Crushers, conveyors, and drilling equipment

- Marine Applications: Propeller shafts, rudder bearings, and deck machinery

- Steel Mills: Rolling mills, continuous casting machines, and furnace equipment

- Power Generation: Turbines, generators, and pumps

- Oil and Gas Industry: Compressors, pumps, and drilling equipment

- Automotive Industry: Engine components and transmission systems

- Paper and Pulp Mills: Rollers, presses, and drying cylinders

- Agricultural Machinery: Tractors, harvesters, and irrigation systems

- Material Handling Equipment: Forklifts, cranes, and conveyor systems

Quality Control:

We implement rigorous quality control measures throughout our production process.

Factory related:

Provide suitable bearing products and supporting services according to the needs of different customers

Packaging and Transportation:

We ensure secure packaging and reliable shipping for all orders.

Shipping Samples:

Sample orders are available for testing and evaluation.

Qualification Certification:

We hold ISO 9001 certification for quality management.

Production process related:

Select appropriate raw materials to produce bearing products that meet technical requirements

Exhibitions:

We regularly participate in international trade shows to showcase our products.

FAQ:

-

What is the typical lead time for the Cupb10Sn10 Bimetallic Bearing?

Our standard lead time is 2-4 weeks, depending on specifications and quantity.

-

Can you provide custom sizes for the products?

Yes, we offer customization services to meet specific application requirements.

-

What lubrication is recommended for the products?

While self-lubricating, these bearings perform best with proper lubrication. We recommend consulting our technical team for specific recommendations based on your application.

-

How do products compare to other bearing materials?

CuPb10Sn10 bearings offer an excellent balance of load capacity, wear resistance, and conformability, making them superior to many alternatives in high-load, low-speed applications.

-

What is the expected service life of the products?

Service life varies depending on operating conditions, but these bearings typically offer extended life compared to conventional options when properly maintained.

Contact Us:

For more information about our CuPb10Sn10 Bimetallic bearings or to discuss your specific application needs, please contact our team at info@wingold.cc. Our experts are ready to provide you with tailored solutions and support to enhance your equipment's performance and reliability.

Learn about our latest products and discounts through SMS or email