- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

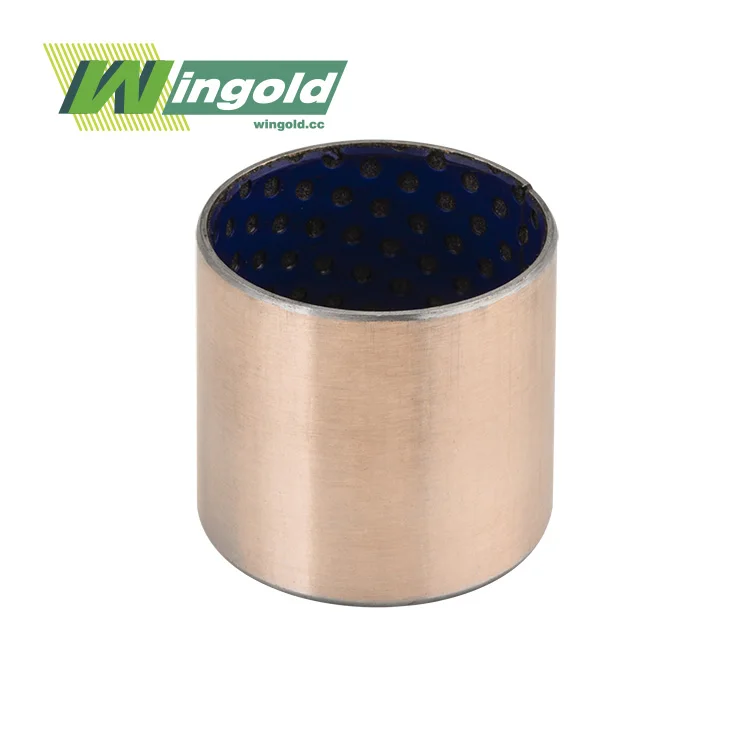

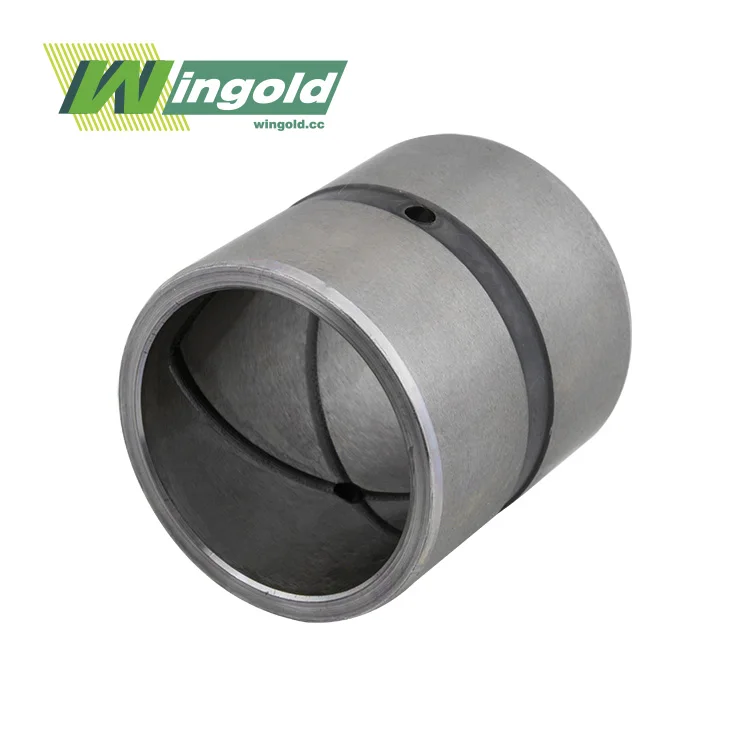

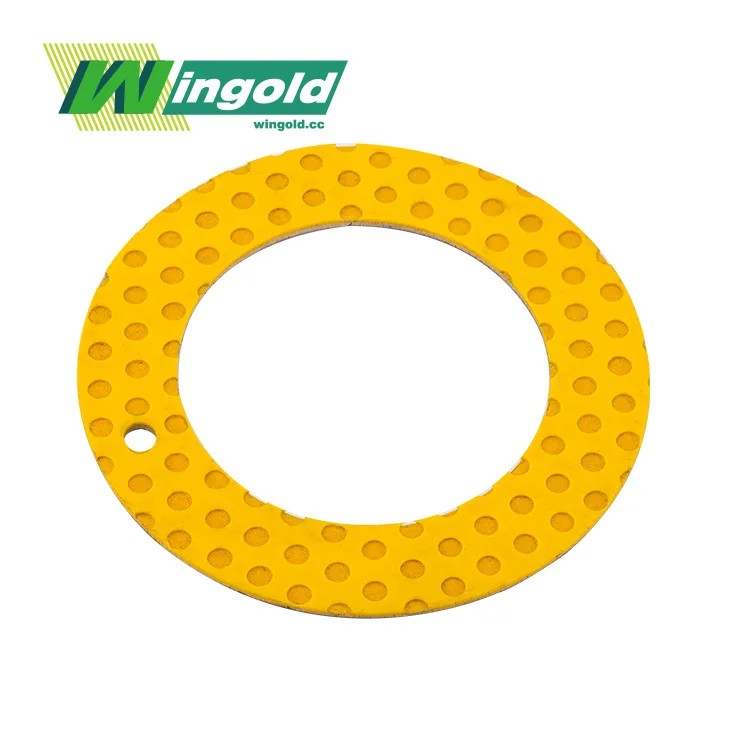

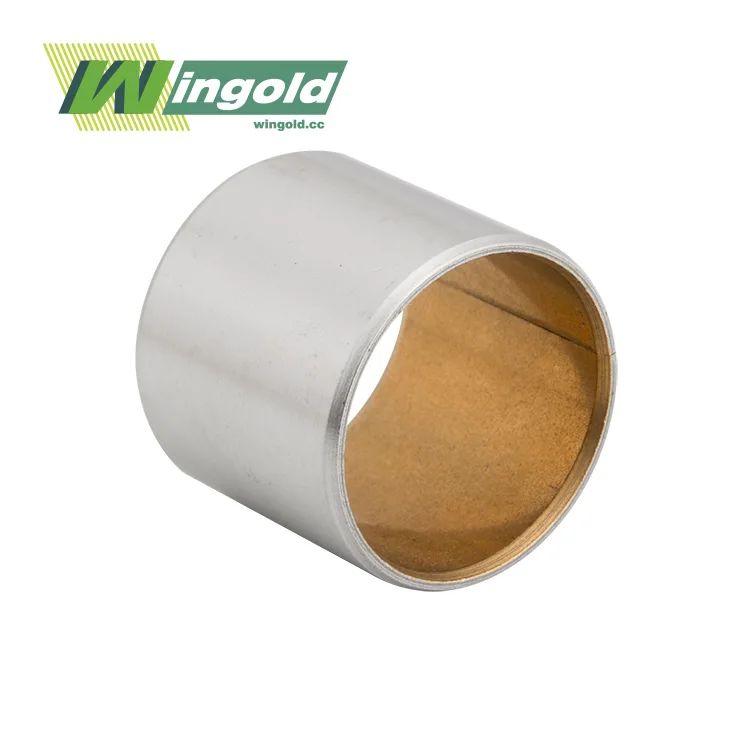

Oil Impregnated Sleeve Bearings

Oil Impregnated Sleeve Bearings: High-Performance Solutions for Your Industrial Needs

Jiashan Wingold Bearing Co., Ltd. is a leading manufacturer and supplier of oil impregnated sleeve bearings. We pride ourselves on delivering top-quality, cost-effective solutions that meet the diverse needs of global B2B buyers. Our extensive experience, cutting-edge technology, and commitment to excellence set us apart in the sliding bearing industry.

Oil Impregnated Sleeve Bearings Introduction

Our oil impregnated sleeve bearings are designed to deliver outstanding performance and long - term durability across numerous industrial applications. These self - lubricating bearings are engineered to function smoothly and effectively, even in tough environments. We produce bearings with exceptional wear resistance, low friction, and minimal maintenance needs by infusing high - grade porous bronze with specialized lubricating oils. The distinct structure of our products enables continuous lubrication during their entire service life. When the bearing is in operation, the heat produced makes the oil expand, forming a thin layer on the bearing's surface. This layer offers continuous lubrication, decreasing wear and extending the lifespan of both the bearing and the shaft.

Specifications:

| Parameter | Value |

|---|---|

| Inner Diameter | 3mm - 300mm |

| Outer Diameter | 6mm - 350mm |

| Length | 3mm - 300mm |

| Operating Temperature | -40°C to +150°C |

| Load Capacity | Up to 140 N/mm² |

| Maximum Speed | Up to 2 m/s |

| Friction Coefficient | 0.03 - 0.08 |

Why Choose Us?

- Over two decades of industry expertise

- Cutting - edge manufacturing facilities

- Customization possibilities to fulfill specific needs

- Stringent quality control procedures

- Competitive pricing along with volume - based discounts

- Professional technical support and engineering aid

- Quick turnaround periods and dependable delivery

- Dedication to innovation and ongoing enhancement

Material:

Our oil impregnated sleeve bearings are primarily manufactured using sintered bronze, a material known for its excellent mechanical properties and porosity. The bronze matrix is impregnated with high-quality lubricating oils, carefully selected to suit various operating conditions and temperature ranges.

Product Advantages:

- Self-Lubrication: Our bearings provide consistent lubrication without the need for external greasing, reducing maintenance costs and downtime.

- Low Friction: The oil-impregnated structure ensures minimal friction, leading to smoother operation and reduced energy consumption.

- Wear Resistance: The combination of durable bronze material and constant lubrication results in exceptional wear resistance, extending the lifespan of both the bearing and mating components.

- Corrosion Resistance: The bronze material offers inherent resistance to corrosion, making these bearings suitable for use in harsh environments.

- Cost-Effectiveness: With their long service life and minimal maintenance requirements, our products offer excellent value for money.

- Versatility: These bearings can operate effectively in a wide range of temperatures and load conditions, making them suitable for diverse applications.

- Noise Reduction: The oil film created during operation helps dampen vibrations, resulting in quieter machine operation.

Application Areas:

- Automotive Industry: Used in steering systems, suspension components, and engine accessories.

- Aerospace: Found in aircraft landing gear, flap tracks, and control surfaces.

- Industrial Machinery: Applied in conveyor systems, packaging equipment, and printing presses.

- Agricultural Equipment: Utilized in tractors, harvesters, and irrigation systems.

- Construction Equipment: Incorporated in excavators, bulldozers, and cranes.

- Renewable Energy: Used in wind turbines and solar tracking systems.

- Marine Applications: Found in ship rudder bearings and propeller shafts.

- Appliances: Used in washing machines, dryers, and refrigerators.

- Office Equipment: Applied in printers, copiers, and paper handling systems.

- Robotics and Automation: Utilized in robotic arms, linear actuators, and conveyor systems.

Our products are crafted to satisfy the requirements of these varied applications. They provide reliability, extended lifespan, and top - notch performance within different industries.

Quality Control:

We implement rigorous quality control measures throughout our production process.

Factory related:

Provide suitable bearing products and supporting services according to the needs of different customers

Packaging and Transportation:

We ensure secure packaging and reliable shipping for all orders.

Shipping Samples:

Sample orders are available for testing and evaluation.

Qualification Certification:

We hold ISO 9001 certification for quality management.

Production process related:

Select appropriate raw materials to produce bearing products that meet technical requirements

Exhibitions:

We regularly participate in international trade shows to showcase our products.

FAQ:

Q: What is the typical lead time for custom orders?

A: Our standard lead time for custom orders is 2-3 weeks, depending on the complexity and quantity of the order.

Q: Can you provide technical assistance for bearing selection?

A: Yes, our team of engineers is available to help you select the most suitable bearing for your application.

Q: What is the minimum order quantity?

A: While we welcome orders of all sizes, our minimum order quantity is typically 100 pieces for standard sizes.

Q: Do you offer any guarantees on your products?

A: We offer a 12-month warranty on all our products against manufacturing defects.

Q: How do I clean and maintain products?

A: These bearings are generally maintenance-free. However, if cleaning is necessary, use a soft cloth and mild solvent, avoiding harsh chemicals that could remove the impregnated oil.

Contact Us:

For more information about our oil impregnated sleeve bearings or to discuss your specific requirements, please contact us at info@wingold.cc. Our team is ready to provide you with expert advice and support to ensure you find the perfect bearing solution for your needs.

Learn about our latest products and discounts through SMS or email