- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Bimetallic Bushing Material

Bimetallic Bushing Material: Innovative Solutions from Jiashan Wingold Bearing Co., Ltd.

At Jiashan Wingold Bearing Co., Ltd., we pride ourselves on being a leading manufacturer and supplier of high-quality bimetallic bushing materials. Our innovative solutions offer superior performance, reliability, and cost-effectiveness, making us the preferred choice for global B2B buyers seeking top-tier sliding bearing solutions.

Product Description:

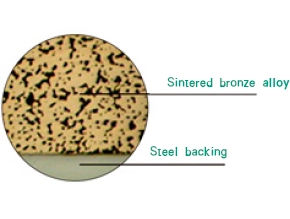

Our products represent the pinnacle of sliding bearing technology, combining the strengths of two carefully selected metals to create a product that excels in performance and durability. These bushings feature a strong steel backing for structural integrity and a specialized alloy lining that provides exceptional tribological properties.

Designed to meet the demanding needs of various industries, our bimetallic bushings offer:

- High load-bearing capacity

- Low friction coefficients

- Excellent wear resistance

- Superior thermal conductivity

- Corrosion resistance

- Self-lubricating properties

Specifications:

| Property | Value |

|---|---|

| Inner Diameter | 10mm - 500mm |

| Wall Thickness | 1mm - 50mm |

| Length | Up to 1000mm |

| Operating Temperature | -40°C to 280°C |

| Maximum Load | Up to 250 MPa |

| Friction Coefficient | 0.02 - 0.08 |

Why Choose Us?

- Over 20 years of industry experience

- Cutting-edge research and development

- Customizable solutions for specific applications

- Rigorous quality control processes

- Global supply chain reliability

- Comprehensive technical support

- Competitive pricing

- Eco-friendly manufacturing processes

Material:

Our bimetallic bushing materials typically consist of:

- Steel backing: Provides structural strength and heat dissipation

- Bronze or copper-based alloy lining: Offers excellent friction and wear properties

- Optional PTFE or other polymer overlays: Enhances self-lubricating capabilities

Product Advantages:

Jiashan Wingold's products offer a host of benefits that set them apart in the market:

- Exceptional Performance: Our bushings deliver outstanding load-bearing capacity and low friction coefficients, ensuring smooth operation even under extreme conditions.

- Longevity: The combination of durable steel backing and wear-resistant alloy lining significantly extends the service life of your equipment, reducing maintenance costs and downtime.

- Versatility: Our bimetallic bushings can be tailored to suit a wide range of applications, from automotive to heavy machinery, offering flexibility in design and implementation.

- Cost-Effectiveness: While providing premium quality, our products offer excellent value for money, helping you optimize your overall system costs.

- Thermal Management: Superior heat dissipation properties ensure stable performance across a wide temperature range, enhancing reliability in diverse operating environments.

Application Areas:

Our Bimetallic Bushing Material find applications across numerous industries, including:

- Automotive: Components within engines, suspension frameworks, and steering apparatuses.

- Aerospace: Landing gear assemblies, flight control subsystems, and engine mounting structures.

- Industrial Machinery: Hydraulic cylinder units, compressor equipment, and pump mechanisms.

- Construction Equipment: Excavation machinery such as excavators, bulldozing equipment, and crane systems.

- Marine: Propeller shaft arrangements, rudder bearing set - ups, and deck - based equipment.

- Energy: Wind turbine installations, hydroelectric generator units, and oil and gas industry machinery.

- Agricultural Equipment: Tractor units, harvesting machinery, and irrigation system components.

- Material Handling: Forklift trucks, conveyor system set - ups, and packaging machinery.

By choosing Jiashan Wingold's products, you're investing in a solution that combines cutting-edge technology with proven reliability, ensuring optimal performance for your specific application needs.

Quality Control:

We implement rigorous quality control measures throughout our production process.

Factory related:

Provide suitable bearing products and supporting services according to the needs of different customers

Packaging and Transportation:

We ensure secure packaging and reliable shipping for all orders.

Shipping Samples:

Sample orders are available for testing and evaluation.

Qualification Certification:

We hold ISO 9001 certification for quality management.

Production process related:

Select appropriate raw materials to produce bearing products that meet technical requirements

Exhibitions:

We regularly participate in international trade shows to showcase our products.

FAQ:

- What is the typical lead time for custom orders?

We typically process custom orders within 2-4 weeks, depending on specifications and quantity. - Can you provide technical assistance for material selection?

Absolutely! Our engineering team is available to help you choose the best material for your application. - Do you offer warranties on your products?

Yes, we provide warranties based on the specific product and application. Please contact us for details. - How do your bimetallic bushings compare to traditional bronze bushings?

Our bimetallic bushings often offer superior performance, longer life, and better cost-effectiveness compared to traditional bronze bushings. - Can your bushings be used in corrosive environments?

Many of our products are designed to withstand corrosive environments. We can recommend the best option based on your specific conditions.

Contact Us:

For more information about our bimetallic bushing materials or to discuss your specific needs, please contact us at info@wingold.cc. Our team of experts is ready to provide you with the best sliding bearing solutions for your application.

Learn about our latest products and discounts through SMS or email