- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Powdered Metal Bearings

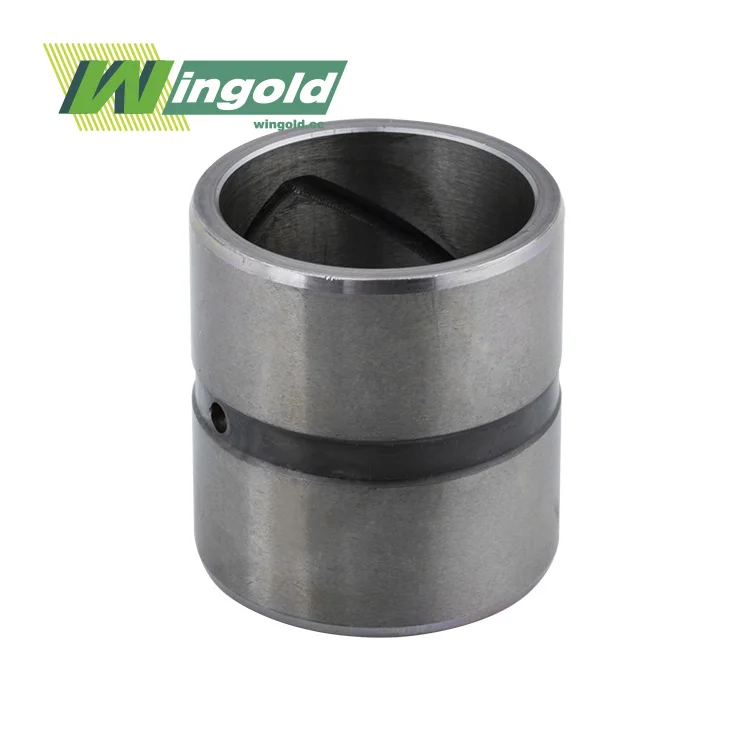

Powdered Metal Bearings: Revolutionizing Industrial Performance

Welcome to Jiashan Wingold Bearing Co., Ltd., your trusted manufacturer and supplier of high-quality powdered metal bearings. Our advanced manufacturing processes and commitment to excellence set us apart, offering you unparalleled performance, durability, and cost-effectiveness in your bearing solutions.

Product Description:

Our offerings stand as the epitome of contemporary bearing innovation. Produced via a revolutionary powder metallurgy technique, these bearings present an exclusive blend of robustness, accuracy, and adaptability. We commence by compacting metal powders, which are then subjected to high - temperature sintering. This process results in bearings with precisely regulated porosity. This porosity is key, as it enables exceptional oil retention and self - lubricating capabilities. These bearings truly shine in applications that demand minimal friction, substantial wear resistance, and the capacity to function in arduous conditions. Be it within the automotive industry, industrial machinery domain, or aerospace field, our products are meticulously engineered to fulfill your unique requirements and go above and beyond what you anticipate.

The utilization of powder metallurgy not only imparts distinct structural characteristics to our bearings but also enhances their performance attributes. The controlled porosity allows for a continuous supply of lubricant, reducing the risk of component failure due to friction - induced wear. In the automotive sector, for instance, these bearings can withstand the high - stress, high - temperature conditions within engines, ensuring smooth operation and longer - lasting performance. Similarly, in industrial machinery where heavy loads and continuous operation are the norm, and in the aerospace industry where reliability is non - negotiable, our bearings prove to be a reliable and high - performing solution.

Specifications:

| Property | Value |

|---|---|

| Material | Bronze, Iron, or Custom Alloys |

| Density | 6.0 - 7.5 g/cm³ |

| Porosity | 10% - 25% |

| Operating Temperature | -40°C to 350°C |

| Load Capacity | Up to 140 MPa |

| Friction Coefficient | 0.1 - 0.3 |

Why Choose Us?

- Over 20 years of industry experience

- Cutting-edge manufacturing facilities

- Customization capabilities to meet your specific requirements

- Rigorous quality control processes

- Competitive pricing without compromising on quality

- Excellent customer support and technical assistance

- Fast turnaround times and reliable delivery

Material:

Our powdered metal bearings are primarily made from bronze or iron-based alloys. We can also create custom alloy compositions to suit your specific application needs. The powder metallurgy process allows us to fine-tune material properties, ensuring optimal performance in various operating conditions.

Product Advantages:

The products offer numerous advantages over traditional bearing types. Their porous structure allows for oil impregnation, creating a self-lubricating effect that significantly reduces maintenance requirements and extends service life. This feature is particularly beneficial in hard-to-reach areas or applications where frequent lubrication is impractical.

The manufacturing process enables precise control over material composition and density, resulting in bearings with excellent dimensional stability and consistent performance. Our products also exhibit superior wear resistance and can operate effectively in high-temperature environments.

Another key advantage is the ability to incorporate solid lubricants directly into the bearing material during the manufacturing process. This feature enhances the bearings' low-friction properties and makes them ideal for use in applications where external lubrication is undesirable or impossible.

Furthermore, the products are highly cost-effective. The manufacturing process allows for near-net shape production, minimizing material waste and reducing machining costs. This efficiency translates to competitive pricing for our customers without compromising on quality or performance.

Application Areas:

- Automotive: Engine components, transmission systems, steering mechanisms

- Industrial Machinery: Pumps, compressors, conveyor systems, printing presses

- Aerospace: Aircraft landing gear, hydraulic systems, flight control mechanisms

- Home Appliances: Washing machines, dishwashers, refrigerators

- Agricultural Equipment: Tractors, harvesters, irrigation systems

- Construction Equipment: Excavators, bulldozers, cranes

- Robotics and Automation: Joint mechanisms, linear motion systems

Quality Control:

Factory related:

Packaging and Transportation:

Shipping Samples:

Qualification Certification:

Production process related:

Exhibitions:

FAQ:

-

What is the typical lead time for the Powdered Metal Bearings?

Our standard lead time is 2-3 weeks, depending on the order quantity and specifications.

-

Can you produce custom products?

Yes, we specialize in custom solutions. Our engineering team will work closely with you to design and manufacture bearings that meet your specific requirements.

-

What industries do you primarily serve?

While we serve a wide range of industries, our primary focus is on automotive, industrial machinery, and aerospace sectors.

-

How do the products compare to traditional bearings in terms of cost?

The products often offer a more cost-effective solution, especially for high-volume production, due to reduced material waste and machining costs.

-

What is the typical lifespan of your products?

The lifespan varies depending on the application and operating conditions. However, our bearings are designed for long-term performance and often outlast traditional bearings in similar applications.

Contact Us:

Ready to revolutionize your bearing solutions with our high-performance powdered metal bearings? Contact us today at info@wingold.cc to discuss your needs and discover how we can help optimize your operations.

Learn about our latest products and discounts through SMS or email