- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

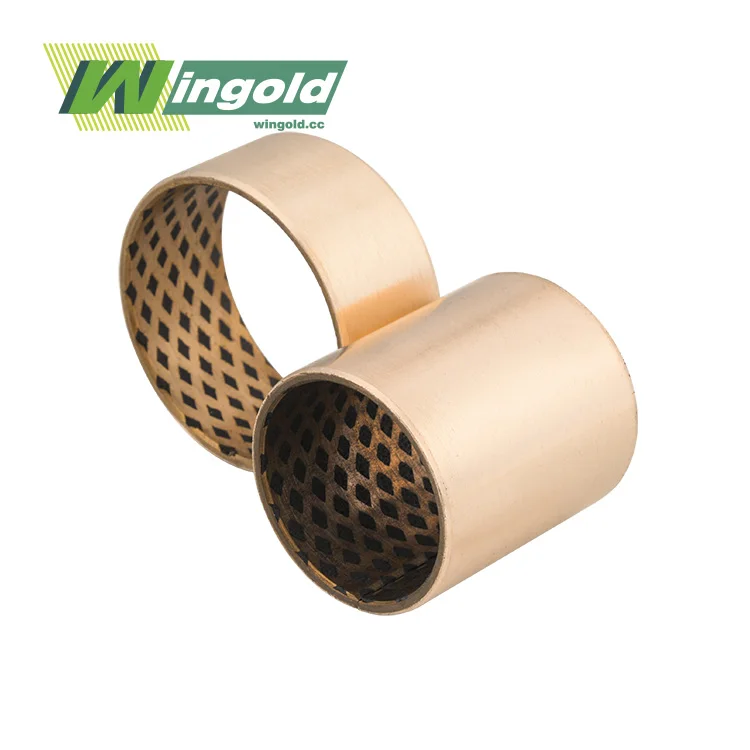

Cupb10Sn10 Bushing

CuPb10Sn10 Bushing: High-Performance Sliding Bearings by Jiashan Wingold

Jiashan Wingold Bearing Co., Ltd. is a leading CuPb10Sn10 bushing manufacturer and supplier. Our expertise in sliding bearing solutions sets us apart, offering superior quality, customization options, and excellent customer service. With our products, you'll experience enhanced performance, durability, and cost-effectiveness in your applications.

Product Description

Our products are engineered for excellence, combining the strength of copper with the self-lubricating properties of lead and tin. These precision-crafted components are designed to meet the demanding needs of various industries, offering reliable performance in high-load and low-speed applications.

The unique alloy composition of our products provides:

- Exceptional load-bearing capacity

- Low friction coefficient

- Excellent wear resistance

- High thermal conductivity

- Corrosion resistance

Whether you're in automotive manufacturing, heavy machinery, or industrial equipment production, our CuPb10Sn10 bushings deliver consistent quality and performance you can trust.

Specifications

| Property | Value |

|---|---|

| Copper (Cu) | 80% |

| Lead (Pb) | 10% |

| Tin (Sn) | 10% |

| Density | 8.8 g/cm³ |

| Hardness (HB) | 50-65 |

| Maximum PV value | 1.8 MPa·m/s |

| Operating Temperature | -40°C to 350°C |

| Coefficient of Friction | 0.10-0.20 |

Why Choose Us?

- Industry expertise since 2016

- Customization capabilities to meet your specific needs

- Rigorous quality control processes

- Competitive pricing without compromising on quality

- Prompt delivery and reliable supply chain

- Comprehensive technical support and after-sales service

- Commitment to innovation and continuous improvement

- Global shipping capabilities

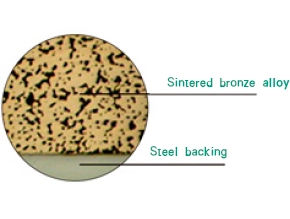

Material

Our Cupb10Sn10 Bushing are crafted from a carefully formulated alloy consisting of:

- 80% Copper: Provides strength and thermal conductivity

- 10% Lead: Enhances self-lubricating properties

- 10% Tin: Improves wear resistance and overall performance

This balanced composition ensures optimal performance across a wide range of applications, making our bushings a versatile choice for your bearing needs.

Product Advantages

- Superior Load Capacity: Our products excel in high-load environments, offering reliable performance even under extreme pressure. This makes them ideal for heavy-duty applications where standard bearings might fail.

- Self-Lubricating Properties: The lead content in our bushings provides excellent self-lubrication, reducing the need for frequent maintenance and extending the life of your machinery. This self-lubricating feature is particularly beneficial in applications where regular lubrication is challenging or impossible.

- Thermal Stability: With an impressive operating temperature range of -40°C to 350°C, our products maintain their performance across diverse thermal conditions. This stability ensures consistent operation in both extremely cold and hot environments.

- Wear Resistance: The addition of tin to the alloy significantly enhances wear resistance, prolonging the lifespan of your bearings and reducing replacement frequency. This translates to lower maintenance costs and increased uptime for your equipment.

- Customization Options: We understand that one size doesn't fit all. Our state-of-the-art manufacturing processes allow us to tailor our products to your exact specifications, ensuring a perfect fit for your unique applications.

Application Areas

Our Cupb10Sn10 Bushing find applications across various industries, including:

- Automotive: Engine components, transmission systems, suspension parts

- Heavy Machinery: Construction equipment, agricultural machinery, mining equipment

- Marine: Propeller shaft bearings, rudder bearings, deck equipment

- Aerospace: Landing gear components, flap tracks, actuator bearings

- Industrial Equipment: Pumps, compressors, conveyor systems, hydraulic cylinders

- Power Generation: Turbine bearings, generator components

- Oil and Gas: Drilling equipment, wellhead components, valve bushings

- Railway: Locomotive engine bearings, bogie components, door mechanisms

- Material Handling: Forklift mast bearings, crane components, elevator guide bushings

The versatility of our products makes them an excellent choice for applications requiring high load capacity, low friction, and reliable performance in challenging environments.

Quality Control:

We implement rigorous quality control measures throughout our production process.

Factory related:

Provide suitable bearing products and supporting services according to the needs of different customers

Packaging and Transportation:

We ensure secure packaging and reliable shipping for all orders.

Shipping Samples:

Sample orders are available for testing and evaluation.

Qualification Certification:

We hold ISO 9001 certification for quality management.

Production process related:

Select appropriate raw materials to produce bearing products that meet technical requirements

Exhibitions:

We regularly participate in international trade shows to showcase our products.

FAQ

Q: What is the minimum order quantity for the Cupb10Sn10 Bushing?

A: We offer flexible order quantities to meet your needs. Contact us for details.

Q: Can you provide custom sizes for the products?

A: Absolutely! We specialize in customization. Share your requirements, and we'll create bushings to your specifications.

Q: How do products compare to other bearing materials?

A:The products offer an excellent balance of load capacity, self-lubrication, and wear resistance, making them superior for many high-load, low-speed applications.

Q: What is the typical lead time for orders?

A: Lead times vary based on order size and customization requirements. We strive for quick turnarounds and will provide a specific timeline upon order confirmation.

Q: Do you offer technical support for installation and maintenance?

A: Yes, our team of experts is available to provide guidance on installation, maintenance, and troubleshooting to ensure optimal performance of your products.

Contact Us

Ready to enhance your machinery's performance with our high-quality CuPb10Sn10 bushings? Contact us today at info@wingold.cc for quotes, technical support, or to discuss your custom bearing needs. Let's work together to find the perfect sliding bearing solution for your application!

Learn about our latest products and discounts through SMS or email