- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

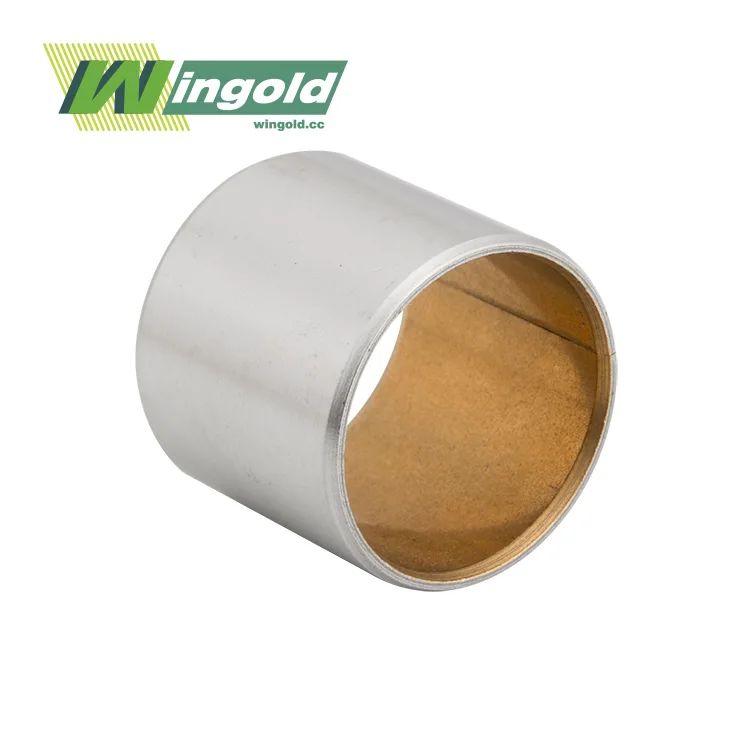

Bimetallic Self Lubricating Bearing

Bimetallic Self Lubricating Bearing: Superior Performance, Unmatched Reliability

Jiashan Wingold Bearing Co., Ltd. is a leading manufacturer and supplier of bimetallic self lubricating bearings. Our expertise in sliding bearing solutions, coupled with advanced manufacturing techniques, allows us to deliver high-quality, long-lasting bearings that meet the diverse needs of global industries. Wingold's products offer exceptional performance, reduced maintenance, and cost-effectiveness for your applications.

Bimetallic Self Lubricating Bearing Description:

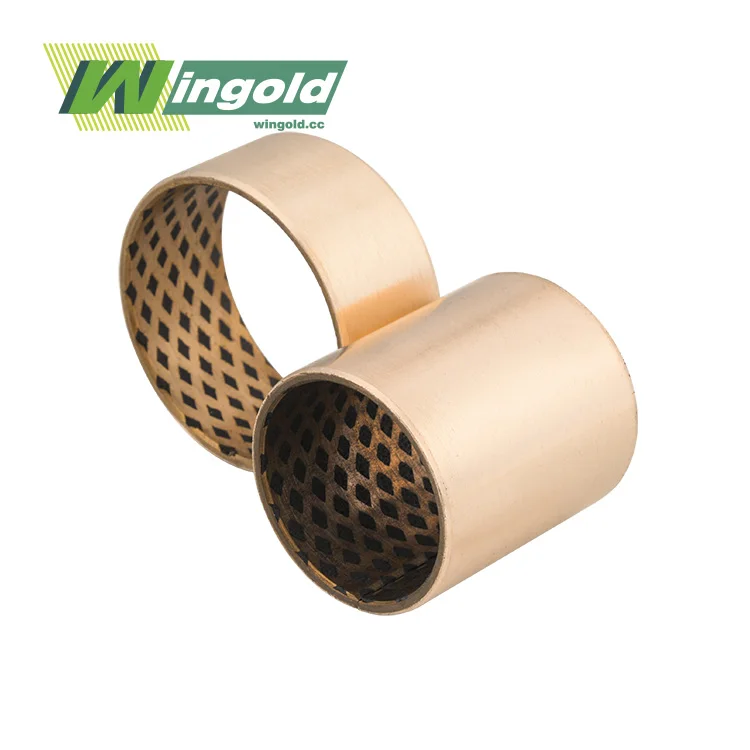

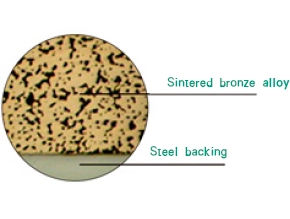

Our products are meticulously engineered to deliver preeminent performance within exacting environments. These innovative bearings integrate the robustness of a steel substrate with a low - friction, self - lubricating layer, commonly composed of bronze or aluminum alloy. This distinctive construction confers multiple benefits:

- Extended service life

- Reduced friction and wear

- Excellent load-bearing capacity

- Ability to operate in high-temperature conditions

- Resistance to corrosion and chemical attack

The self - lubricating characteristics of these bearings obviate the necessity for external lubrication. This not only diminishes maintenance requisites but also enhances the overall reliability of the system. Our products find applicability across a broad spectrum of domains, encompassing automotive, aerospace, industrial machinery, and marine equipment sectors.

Specifications:

| Parameter | Value |

|---|---|

| Material | Steel backing with bronze/aluminum alloy lining |

| Size Range | 8mm - 300mm (inner diameter) |

| Load Capacity | Up to 250 MPa |

| Operating Temperature | -40°C to 280°C |

| Friction Coefficient | 0.02 - 0.08 |

| Wear Rate | < 20 μm/1000h |

Why Choose Us?

- Over 20 years of industry experience

- Customized solutions tailored to your specific needs

- State-of-the-art manufacturing facilities

- Rigorous quality control processes

- Competitive pricing and flexible delivery options

- Comprehensive technical support and after-sales service

- Commitment to innovation and continuous improvement

- Global distribution network for reliable supply

Material:

Our products feature a steel backing for strength and dimensional stability, combined with a carefully selected self-lubricating layer. The lining material, typically bronze or aluminum alloy, is impregnated with solid lubricants such as PTFE or graphite. This combination ensures optimal performance and longevity across various operating conditions.

Product Advantages:

Wingold's bimetallic self lubricating bearings offer numerous benefits that set them apart from traditional bearings:

- Maintenance-Free Operation: The self-lubricating properties eliminate the need for regular greasing or oiling, reducing downtime and maintenance costs.

- High Load Capacity: The steel backing provides excellent structural integrity, allowing our bearings to withstand heavy loads and shock loads.

- Low Friction and Wear: The self-lubricating layer ensures smooth operation and minimal wear, even in challenging environments.

- Temperature Resistance: Our bearings maintain their performance across a wide temperature range, making them suitable for diverse applications.

- Corrosion Resistance: The combination of materials offers excellent protection against corrosion and chemical attack.

- Cost-Effectiveness: With their extended service life and reduced maintenance requirements, our bearings provide significant long-term cost savings.

- Environmentally Friendly: The elimination of external lubricants reduces the risk of contamination and aligns with eco-friendly practices.

Application Areas:

- Automotive: Components within suspension systems, steering mechanisms, and transmission assemblies.

- Aerospace: Landing gear of aircraft, flap track mechanisms, and hydraulic subsystems.

- Industrial Machinery: Printing press equipment, textile manufacturing machinery, and packaging machinery units.

- Construction Equipment: Excavator machinery, bulldozer equipment, and crane systems.

- Marine: Rudder bearing systems of ships, propeller shaft bearing arrangements, and deck - mounted equipment.

- Agricultural Machinery: Tractor units, harvester machinery, and irrigation system components.

- Energy Sector: Wind turbine installations, hydroelectric power generation plants, and oil and gas industry equipment.

- Material Handling: Conveyor systems, elevator mechanisms, and forklift trucks.

Quality Control:

Factory related:

Packaging and Transportation:

Shipping Samples:

Qualification Certification:

Production process related:

Exhibitions:

FAQ:

-

What is the typical lifespan of your products?

The lifespan varies depending on the application, but our bearings typically last 2-3 times longer than conventional bearings under similar conditions.

-

Can these bearings be customized for specific applications?

Yes, we offer customization services to meet your unique requirements, including size, material composition, and performance characteristics.

-

How do I determine the right bimetallic self lubricating bearing for my application?

Our team of experts will work closely with you to analyze your specific needs and recommend the most suitable bearing solution.

-

What industries do you primarily serve?

We serve a wide range of industries, including automotive, aerospace, industrial machinery, marine, and energy sectors.

-

How do your bearings compare to plastic bearings in terms of performance?

Our products generally offer higher load capacity, better temperature resistance, and longer service life compared to plastic bearings.

Contact Us:

For more information about our bimetallic self lubricating bearings or to discuss your specific requirements, please contact us at info@wingold.cc. Our team is ready to provide expert guidance and support to help you find the perfect bearing solution for your needs.

Learn about our latest products and discounts through SMS or email