- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

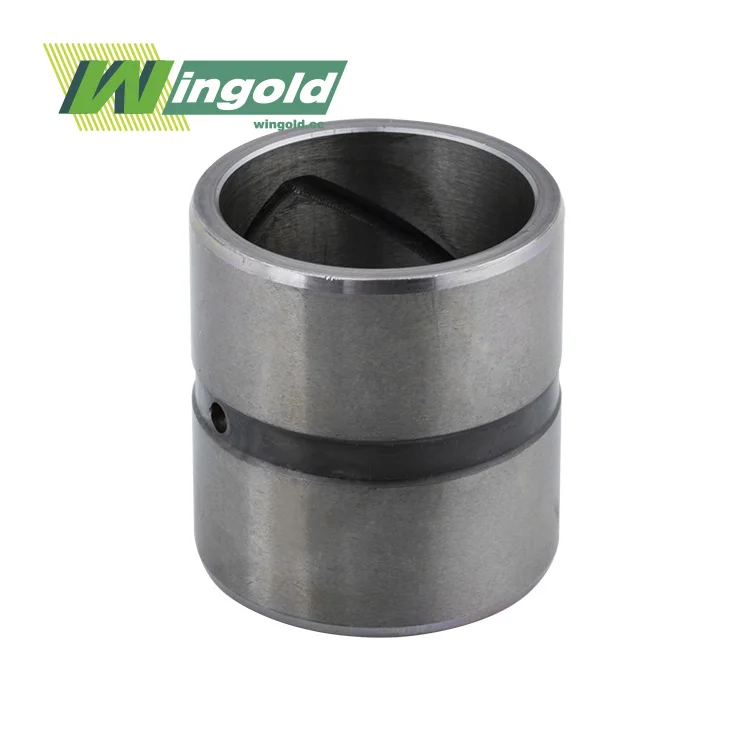

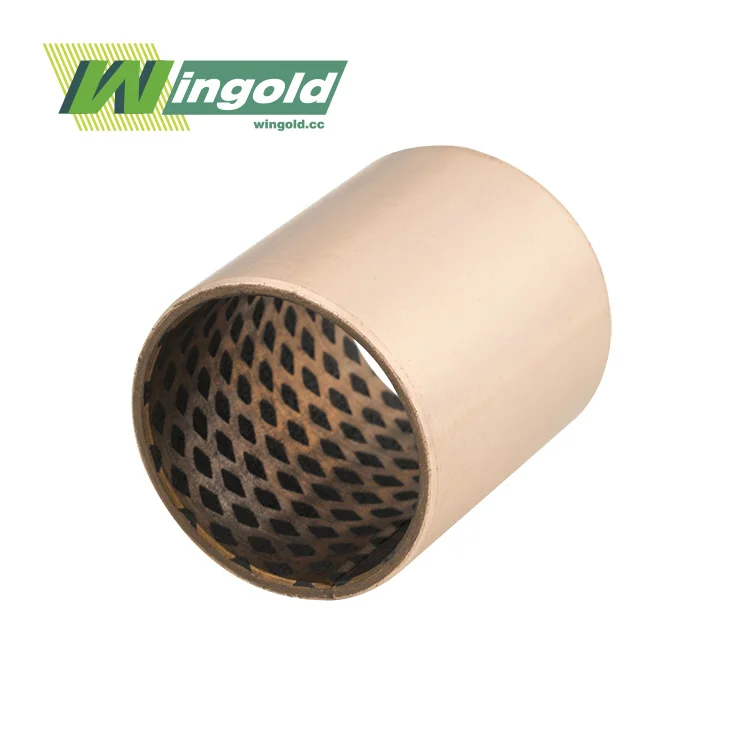

Oil Impregnated Brass Bushings

Jiashan Wingold Bearing Co., Ltd.: Your Premier Oil Impregnated Brass Bushings Manufacturer & Supplier

Our expertise in sliding bearing solutions ensures superior performance, extended service life, and cost-effective operation for your applications. Trust Wingold for precision-engineered oil Impregnated brass bushings that exceed industry standards.

Oil Impregnated Brass Bushings Introduction

Our oil Impregnated brass bushings are the epitome of self-lubricating excellence. Crafted from high-quality brass alloys, these bushings are precision-engineered to provide optimal performance in a wide range of applications. The porous structure of our bushings is impregnated with lubricating oil, ensuring smooth operation and reduced friction throughout the bearing's lifespan.

These bushings offer exceptional load-bearing capacity, wear resistance, and thermal stability. The self-lubricating properties eliminate the need for frequent maintenance, making them ideal for applications where regular lubrication is impractical or impossible. Our products are designed to operate efficiently in both low and high-speed conditions, maintaining their performance even under challenging environments.

Specifications:

| Parameter | Value |

|---|---|

| Material | C86300 Brass Alloy |

| Inner Diameter | 3mm - 150mm |

| Outer Diameter | 6mm - 200mm |

| Length | 5mm - 300mm |

| Operating Temperature | -40°C to +150°C |

| Load Capacity | Up to 140 N/mm² |

| Friction Coefficient | 0.08 - 0.15 |

Why Choose Us?

- Over 20 years of industry experience

- State-of-the-art manufacturing facilities

- Rigorous quality control processes

- Customization capabilities to meet specific requirements

- Competitive pricing and flexible ordering options

- Comprehensive technical support and consultation

- Global distribution network for timely delivery

Material:

Our oil impregnated brass bushings are manufactured using premium C86300 brass alloy, known for its excellent mechanical properties and corrosion resistance. This high-performance material ensures durability, dimensional stability, and consistent performance across various operating conditions.

Product Advantages:

Wingold's products offer a multitude of benefits that set them apart in the industry. The self-lubricating nature of these bushings significantly reduces maintenance requirements and extends operational life. Their high load-bearing capacity makes them suitable for demanding applications, while the low friction coefficient ensures smooth movement and reduced wear.

Our bushings excel in both dry and boundary lubrication conditions, providing reliable performance even in the presence of contaminants. The porous structure of the brass allows for oil retention and continuous lubrication, maintaining optimal performance over extended periods. Additionally, these bushings offer excellent dimensional stability, resisting deformation under load and temperature variations.

The corrosion-resistant properties of our brass alloy make these bushings ideal for use in diverse environments, including those exposed to moisture or chemicals. Their ability to operate across a wide temperature range further enhances their versatility, making them suitable for applications from cryogenic to high-temperature settings.

Application Areas:

- Automotive: Steering systems, suspension components, and pedal assemblies

- Aerospace: Landing gear, flap tracks, and control surfaces

- Industrial Machinery: Conveyor systems, packaging equipment, and printing presses

- Agricultural Equipment: Pivots, linkages, and hydraulic cylinders

- Construction Equipment: Excavator arms, loader buckets, and dozer blades

- Marine: Rudder bearings, propeller shafts, and deck equipment

- Renewable Energy: Wind turbine pitch controls and solar panel tracking systems

- Robotics: Joint mechanisms and linear motion systems

- Material Handling: Forklifts, cranes, and lifting equipment

- Home Appliances: Washing machine drums, dishwasher racks, and oven hinges

Quality Control:

We implement rigorous quality control measures throughout our production process.

Factory related:

Provide suitable bearing products and supporting services according to the needs of different customers

Packaging and Transportation:

We ensure secure packaging and reliable shipping for all orders.

Shipping Samples:

Sample orders are available for testing and evaluation.

Qualification Certification:

We hold ISO 9001 certification for quality management.

Production process related:

Select appropriate raw materials to produce bearing products that meet technical requirements

Exhibitions:

We regularly participate in international trade shows to showcase our products.

FAQ:

Q: What is the typical lead time for custom orders?

A: Custom orders typically take 2-3 weeks, depending on specifications and quantity.

Q: Can you provide material certifications?

A: Yes, we provide material certifications and test reports upon request.

Q: What is the minimum order quantity?

A: Our minimum order quantity is 100 pieces for standard sizes.

Q: Do you offer design assistance for custom applications?

A: Absolutely! Our engineering team can assist with custom designs and material selection.

Q: What is the expected lifespan of your products?

A: Lifespan varies by application, but our bushings typically last 3-5 times longer than standard bearings.

Contact Us:

For inquiries or to discuss your specific oil impregnated brass bushings needs, please contact us at info@wingold.cc. Our expert team is ready to provide you with tailored solutions and exceptional service.

Learn about our latest products and discounts through SMS or email