- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

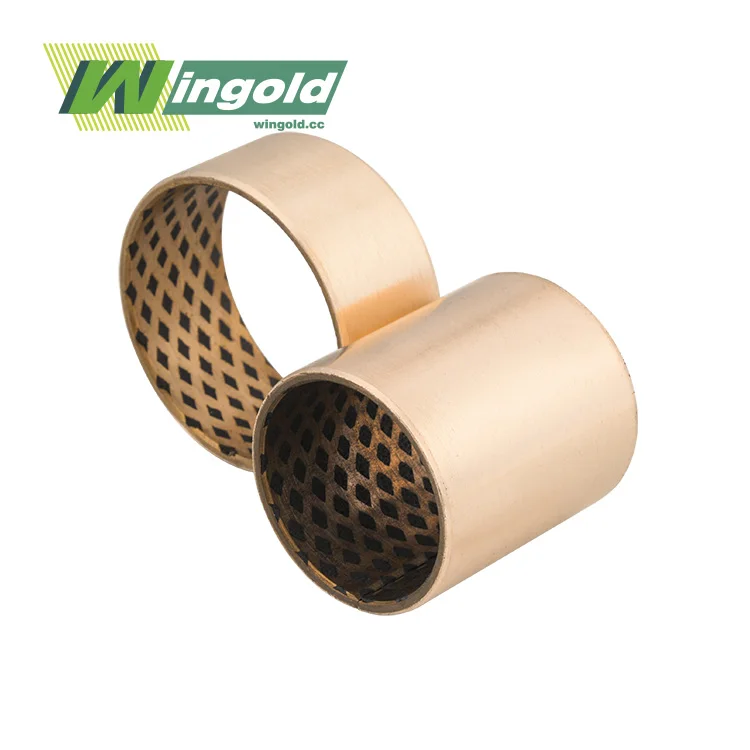

Bimetallic Bushing

Bimetallic Bushings: High-Performance Solutions from Jiashan Wingold Bearing Co., Ltd.

Jiashan Wingold Bearing Co., Ltd. is a leading manufacturer and supplier of premium bimetallic bushings. Our expertise in sliding bearing solutions ensures superior quality, reliability, and performance. With our advanced manufacturing processes and commitment to innovation, we offer products that excel in durability, load capacity, and tribological properties, making us the preferred choice for industries worldwide.

Product Description:

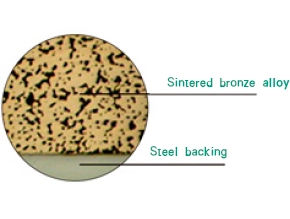

Our products stand as the epitome of sliding bearing technology, integrating two dissimilar metal layers to formulate a robust and highly efficient solution applicable across diverse industrial domains. The outer layer, commonly fabricated from steel, imparts outstanding structural integrity and proficient heat dissipation capabilities. Conversely, the inner layer, which consists of a softer bearing alloy, furnishes superior sliding characteristics and remarkable wear resistance.

These bushings are meticulously engineered to endure high loads, extreme temperature variations, and arduous operating conditions. The bimetallic architecture enables optimal performance in scenarios where conventional single - material bearings might prove inadequate. Our bushings present reduced frictional forces, enhanced heat transfer efficiency, and an extended service lifespan, rendering them an optimal selection for exacting industrial environments.

Specifications:

| Feature | Specification |

|---|---|

| Inner Diameter | 10mm - 500mm |

| Outer Diameter | 12mm - 550mm |

| Length | 10mm - 1000mm |

| Wall Thickness | 1mm - 25mm |

| Operating Temperature | -40°C to 280°C |

| Load Capacity | Up to 250 MPa |

| Friction Coefficient | 0.02 - 0.08 |

Why Choose Us?

- Over 20 years of industry experience

- State-of-the-art manufacturing facilities

- Rigorous quality control processes

- Customization capabilities to meet specific requirements

- Competitive pricing and flexible order quantities

- Global distribution network ensuring timely delivery

- Comprehensive technical support and after-sales service

- Commitment to continuous innovation and improvement

Material:

Our bimetallic bushings are crafted using carefully selected materials to ensure optimal performance. The steel backing provides structural integrity, while the bearing layer is typically composed of advanced alloys such as:

- Aluminum-tin alloys for excellent embedability and conformability

- Copper-lead alloys for high load capacity and thermal conductivity

- Bronze alloys for corrosion resistance and durability

- PTFE-based materials for low friction and dry-running capabilities

Product Advantages:

- Superior Load Capacity: Our products are designed to handle high loads without deformation, making them ideal for heavy-duty applications in industries such as construction, mining, and manufacturing.

- Enhanced Tribological Properties: The carefully engineered bearing layer provides excellent friction reduction and wear resistance, leading to improved efficiency and extended service life of machinery and equipment.

- Excellent Heat Dissipation: The steel backing effectively conducts heat away from the bearing surface, preventing overheating and ensuring consistent performance under demanding conditions.

- Corrosion Resistance: Our bushings are designed to withstand harsh environments, offering protection against chemical corrosion and oxidation, thus maintaining their integrity in challenging industrial settings.

- Dimensional Stability: The bimetallic construction ensures minimal thermal expansion and contraction, maintaining precise tolerances even under fluctuating temperatures.

- Cost-Effectiveness: By combining durability with high performance, our products offer an excellent return on investment, reducing maintenance costs and downtime for our customers.

Application Areas:

- Automotive: Engine components, suspension systems, steering mechanisms

- Heavy Equipment: Excavators, loaders, cranes, and agricultural machinery

- Marine: Propeller shafts, rudder bearings, and deck equipment

- Aerospace: Landing gear, flight control systems, and cargo doors

- Industrial Machinery: Presses, pumps, compressors, and conveyor systems

- Energy Sector: Wind turbines, hydroelectric generators, and oil & gas equipment

- Construction: Concrete mixers, bulldozers, and hydraulic systems

- Mining: Crushers, conveyors, and drilling equipment

Quality Control:

We implement rigorous quality control measures throughout our production process.

Factory related:

Provide suitable bearing products and supporting services according to the needs of different customers

Packaging and Transportation:

We ensure secure packaging and reliable shipping for all orders.

Shipping Samples:

Sample orders are available for testing and evaluation.

Qualification Certification:

We hold ISO 9001 certification for quality management.

Production process related:

Select appropriate raw materials to produce bearing products that meet technical requirements

Exhibitions:

We regularly participate in international trade shows to showcase our products.

FAQ:

-

What is the typical lead time for the Bimetallic Bushing?

Standard sizes are usually available within 2-3 weeks, while custom orders may take 4-6 weeks.

-

Can you provide custom product solutions?

Yes, we offer customization services to meet specific application requirements.

-

What is the minimum order quantity for the products?

We offer flexible order quantities, with minimums starting at 100 pieces for standard sizes.

-

Do you provide technical support for product selection?

Our engineering team is available to assist with product selection and application-specific advice.

-

What warranty do you offer on products?

We provide a standard 12-month warranty against manufacturing defects.

Contact Us:

For more information about our bimetallic bushings or to discuss your specific needs, please contact our sales team at info@wingold.cc. We look forward to providing you with high-performance sliding bearing solutions that drive your business forward.

Learn about our latest products and discounts through SMS or email