- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

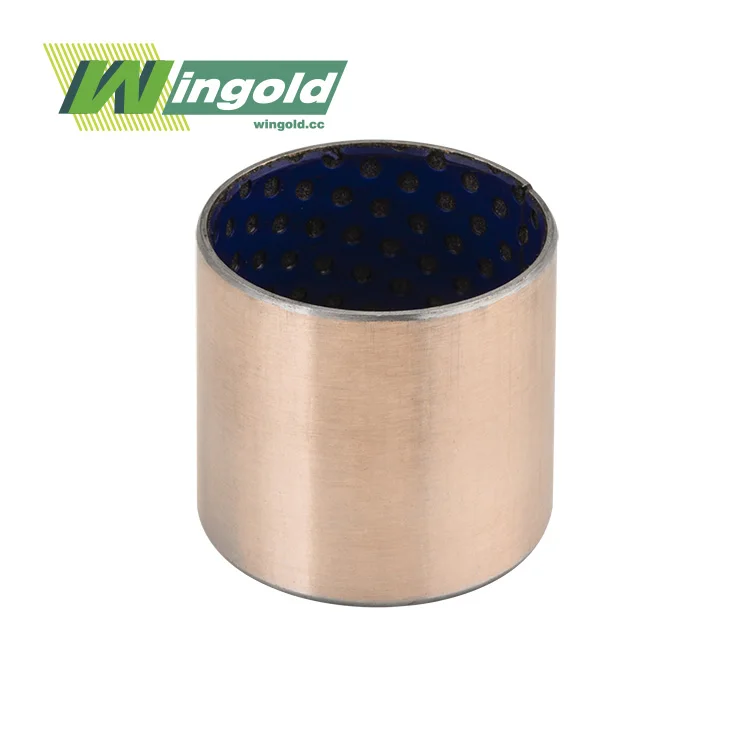

High Temperature Sleeve Bearing

Jiashan Wingold Bearing Co., Ltd.: Your Trusted High Temperature Sleeve Bearing Manufacturer & Supplier

At Jiashan Wingold Bearing Co., Ltd., we pride ourselves on delivering superior high temperature sleeve bearings that outperform industry standards. Our advanced manufacturing processes, coupled with cutting-edge materials, ensure unparalleled durability and reliability in extreme conditions. Choose Wingold for innovative bearing solutions that drive your success.

High Temperature Sleeve Bearing Introduction

Our high temperature sleeve bearings are engineered to excel in the most demanding environments. These precision-crafted components are designed to withstand extreme heat while maintaining optimal performance and longevity. Whether you're in the aerospace, automotive, or industrial sector, our products deliver consistent, reliable operation under the most challenging conditions.

Utilizing advanced materials and state-of-the-art manufacturing techniques, our products offer superior load-bearing capacity, excellent wear resistance, and exceptional thermal stability. These bearings are specifically designed to minimize friction, reduce maintenance requirements, and extend the operational life of your equipment, even in high-temperature applications.

Specifications:

| Feature | Specification |

|---|---|

| Temperature Range | Up to 800°C (1472°F) |

| Coefficient of Friction | 0.02 - 0.08 |

| Load Capacity | Up to 140 MPa |

| Shaft Speed | Up to 2 m/s |

| Inner Diameter | 10mm - 500mm |

| Outer Diameter | 14mm - 560mm |

| Length | 10mm - 1000mm |

Why Choose Us?

- Over 20 years of industry expertise in high temperature bearing solutions

- Customized designs to meet your specific application requirements

- Rigorous quality control and testing procedures

- Competitive pricing without compromising on quality

- Fast turnaround times and reliable global shipping

- Comprehensive technical support and after-sales service

- Commitment to continuous innovation and product improvement

Material

Our high temperature sleeve bearings are crafted from advanced materials such as:

- Self-lubricating graphite composites

- High-performance polymers (PEEK, PPS, PAI)

- Ceramic-metal alloys

- Specialized metal alloys (nickel-based, cobalt-based)

These materials are carefully selected to provide optimal performance in high-temperature environments, offering excellent thermal stability, low friction, and high wear resistance.

Product Advantages

- Exceptional Heat Resistance: Our products maintain their structural integrity and performance at temperatures up to 800°C, ensuring reliability in the most extreme conditions.

- Self-Lubricating Properties: Many of our bearing materials incorporate self-lubricating technologies, reducing the need for external lubrication and minimizing maintenance requirements.

- Low Friction and Wear: Advanced material compositions result in exceptionally low coefficients of friction, reducing energy consumption and extending bearing life.

- Chemical Resistance: Our bearings offer excellent resistance to corrosive chemicals, making them suitable for use in aggressive environments.

- Dimensional Stability: Engineered to maintain their shape and size under high temperatures, ensuring consistent performance throughout their operational life.

- Customizable Solutions: We offer tailored designs to meet your specific application needs, optimizing performance for your unique operating conditions.

- Cost-Effective: Despite their advanced capabilities, our products offer an excellent return on investment through extended service life and reduced maintenance costs.

Application Areas

- Aerospace: Jet engine components, landing gear systems

- Automotive: Turbochargers, exhaust gas recirculation systems

- Steel Industry: Continuous casting machines, rolling mill equipment

- Glass Manufacturing: Annealing lehrs, forming machines

- Power Generation: Steam turbines, gas turbines

- Chemical Processing: Pumps, agitators, mixers in high-temperature reactors

- Food Processing: Industrial ovens, conveyor systems in high-heat areas

- Cement Production: Kiln roller bearings, clinker coolers

- Oil and Gas: Downhole tools, offshore platform equipment

- Waste Incineration: Grate systems, ash handling equipment

- Paper and Pulp: Drying cylinders, calendar rolls

- Textile Industry: Stenter frames, heat-setting machines

Quality Control:

We implement rigorous quality control measures throughout our production process.

Factory related:

Provide suitable bearing products and supporting services according to the needs of different customers

Packaging and Transportation:

We ensure secure packaging and reliable shipping for all orders.

Shipping Samples:

Sample orders are available for testing and evaluation.

Qualification Certification:

We hold ISO 9001 certification for quality management.

Production process related:

Select appropriate raw materials to produce bearing products that meet technical requirements

Exhibitions:

We regularly participate in international trade shows to showcase our products.

FAQ

Q: What is the maximum operating temperature for your sleeve bearings?

A: Our products can operate effectively at temperatures up to 800°C (1472°F), depending on the specific material and design.

Q: Can you provide custom sizes for the products?

A: Yes, we specialize in customizing our bearings to meet your exact specifications and application requirements.

Q: What industries commonly use your products?

A: Our bearings are widely used in aerospace, automotive, steel production, glass manufacturing, and various other industries requiring high-temperature performance.

Q: How do your products contribute to energy efficiency?

A: Our bearings feature low coefficients of friction, reducing energy consumption in your equipment and contributing to overall system efficiency.

Q: What is the typical lead time for custom high temperature sleeve bearings?

A: Lead times vary based on specifications and quantity, but we strive to offer competitive turnaround times. Contact us for a precise estimate.

Contact Us

Ready to elevate your high-temperature applications with our high temperature sleeve bearing? Contact our expert team at info@wingold.cc for personalized solutions and quotes. Let Jiashan Wingold Bearing Co., Ltd. be your partner in achieving optimal performance in extreme conditions.

Learn about our latest products and discounts through SMS or email