- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

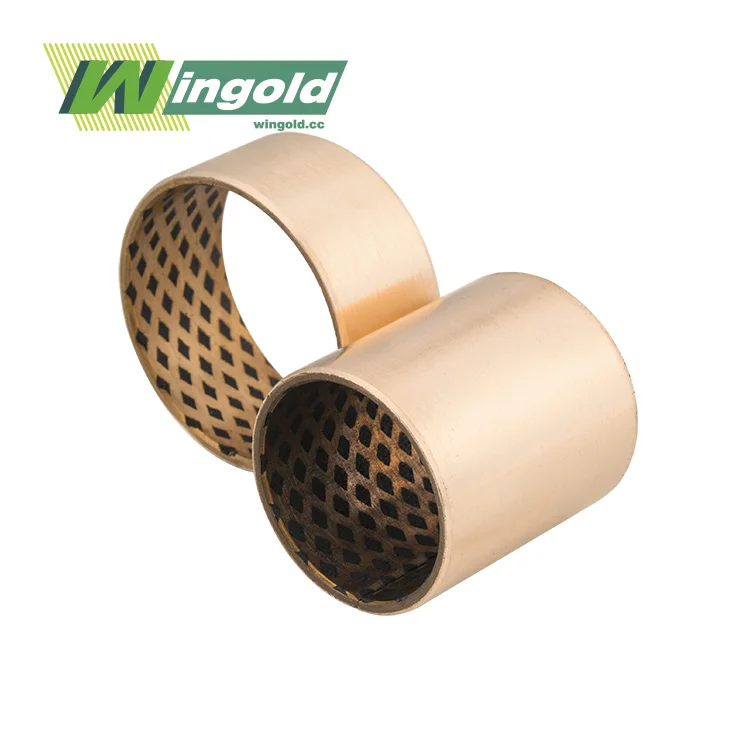

Oil Groove Bushings

Jiashan Wingold Bearing Co., Ltd.: Your Trusted Oil Groove Bushings Manufacturer & Supplier

At Jiashan Wingold Bearing Co., Ltd., we take pride in our expertise as a leading oil groove bushings manufacturer and supplier. Our commitment to quality, innovation, and customer satisfaction sets us apart. With cutting-edge technology and years of industry experience, we deliver superior products that meet the highest standards of performance and reliability.

Oil Groove Bushings Introduction

Our oil groove bushings are meticulously engineered components created to offer the best lubrication and cut down on friction within diverse industrial applications. These bushings have precisely made grooves which enable effective oil spread, making sure of seamless operation and a long service life. Our products are produced with top - grade materials and state - of - the - art production methods, assuring outstanding load - bearing capabilities, wear resistance, and dimensional steadiness.

Specifications:

| Parameter | Value |

|---|---|

| Material | Bronze, Steel, or Custom alloys |

| Inner Diameter | 10mm - 500mm |

| Outer Diameter | 15mm - 600mm |

| Length | 20mm - 1000mm |

| Groove Pattern | Straight, Spiral, or Custom |

| Surface Finish | Ra 0.2 - 3.2 µm |

| Operating Temperature | -40°C to 150°C |

| Load Capacity | Up to 50 MPa |

Why Choose Us?

- Industry-leading expertise in sliding bearing solutions

- Customizable designs to meet specific application requirements

- Rigorous quality control measures ensuring consistent performance

- Competitive pricing without compromising on quality

- Responsive customer support and technical assistance

- Quick turnaround times and reliable global shipping

- Commitment to continuous innovation and improvement

Material:

We provide oil groove bushings crafted from a diverse range of materials. This includes bronze alloys, steel, as well as customized compositions. Our choice of materials is carefully customized to match the unique requirements of your application, guaranteeing peak performance, long - lasting durability, and cost - efficiency.

Product Advantages:

Our products stand out for their exceptional performance and reliability. The precision-engineered grooves ensure consistent oil distribution, minimizing friction and wear even under heavy loads. This design leads to improved energy efficiency and reduced maintenance costs for your machinery.

The versatility of our bushings allows them to excel in diverse operating conditions, from high-speed rotations to slow, oscillating movements. Their self-lubricating properties contribute to extended service life and reduced downtime, making them an ideal choice for critical applications where reliability is paramount.

Furthermore, our products are designed with ease of installation and replacement in mind, reducing maintenance time and associated costs. The superior dimensional stability of our products ensures consistent performance throughout their lifespan, even under varying temperature and load conditions.

Application Areas:

- Automotive Industry: Engine components, suspension systems, steering mechanisms

- Heavy Machinery: Construction equipment, agricultural machinery, mining equipment

- Marine Applications: Propeller shafts, rudder bearings, deck equipment

- Aerospace: Landing gear systems, flight control mechanisms

- Power Generation: Turbines, generators, wind energy systems

- Material Handling: Conveyor systems, lift trucks, cranes

- Oil and Gas: Drilling equipment, pumps, compressors

- Paper and Pulp Industry: Rolling mills, paper making machinery

- Textile Machinery: Spinning and weaving equipment

- Food Processing: Mixers, conveyors, packaging machinery

Our oil groove bushings are versatile enough to meet the demands of various industries, providing reliable performance in both standard and custom applications. Whether you need bushings for high-load, high-speed, or corrosive environments, we have the expertise to deliver the right solution for your specific needs.

Quality Control:

We implement rigorous quality control measures throughout our production process.

Factory related:

Provide suitable bearing products and supporting services according to the needs of different customers

Packaging and Transportation:

We ensure secure packaging and reliable shipping for all orders.

Shipping Samples:

Sample orders are available for testing and evaluation.

Qualification Certification:

We hold ISO 9001 certification for quality management.

Production process related:

Select appropriate raw materials to produce bearing products that meet technical requirements

Exhibitions:

We regularly participate in international trade shows to showcase our products.

FAQ:

Q: What is the minimum order quantity for the products?

A: We offer flexible MOQ options to accommodate various order sizes. Please contact us for details.

Q: Can you provide custom oil groove bushing designs?

A: Absolutely! We specialize in custom solutions tailored to your specific requirements.

Q: What is the typical lead time for oil groove bushing orders?

A: Lead times vary depending on the order specifics, but we strive for quick turnarounds. Contact us for an accurate estimate.

Q: Do you offer technical support for oil groove bushing installation and maintenance?

A: Yes, our team of experts is available to provide comprehensive technical support throughout the product lifecycle.

Q: Are your products compliant with international standards?

A: Our products meet or exceed relevant international standards. We can provide specific compliance information upon request.

Contact Us:

Ready to enhance your machinery's performance with our superior oil groove bushings? Contact us today at info@wingold.cc to discuss your requirements or request a quote. Our team is eager to provide you with the ideal sliding bearing solution for your application.

Learn about our latest products and discounts through SMS or email