- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

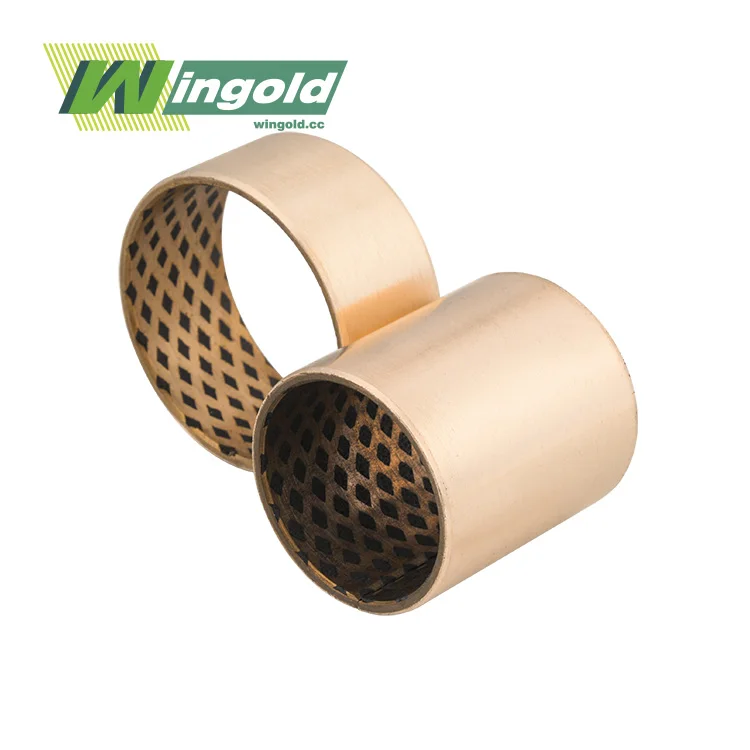

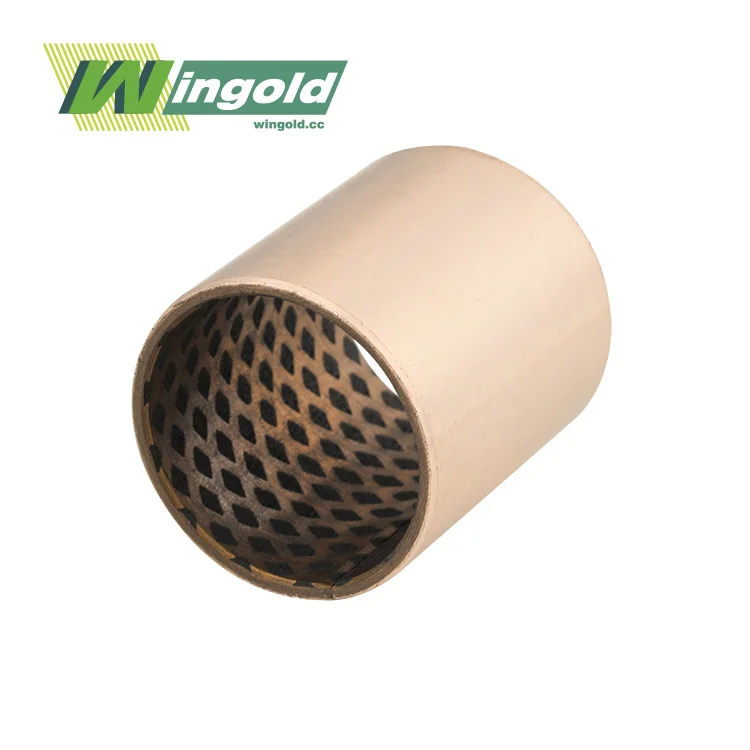

Oil Impregnated Bronze Washer

Jiashan Wingold Bearing Co., Ltd.: Your Trusted Oil Impregnated Bronze Washer Manufacturer & Supplier

Our extensive experience in the sliding bearing industry, coupled with our commitment to innovation and customer satisfaction, sets us apart. We offer superior oil impregnated bronze washers that deliver exceptional performance, longevity, and cost-effectiveness for your applications.

Oil Impregnated Bronze Washer Introduction

Our oil impregnated bronze washers are precision-engineered components designed to provide superior lubrication and wear resistance in a wide range of industrial applications. These self-lubricating washers are manufactured using high-grade bronze alloys and impregnated with specialized oils to ensure optimal performance under various operating conditions. The porous structure of the bronze material allows for continuous lubrication, reducing friction and extending the lifespan of your machinery.

Our products offer excellent load-bearing capacity, making them ideal for both radial and thrust applications. They maintain their dimensional stability even under high temperatures and heavy loads, ensuring consistent performance throughout their service life. With low friction coefficients and outstanding wear resistance, these washers are an excellent choice for applications requiring minimal maintenance and maximum reliability.

Specifications:

| Property | Value |

|---|---|

| Material | Bronze alloy (C86300, C93200, or custom) |

| Oil Content | 25-35% by volume |

| Operating Temperature | -40°C to 150°C |

| Friction Coefficient | 0.08 - 0.15 |

| Load Capacity | Up to 140 N/mm² |

| Inner Diameter | 3mm - 300mm |

| Outer Diameter | 6mm - 350mm |

| Thickness | 0.5mm - 50mm |

Why Choose Us?

- Over 20 years of industry experience

- State-of-the-art manufacturing facilities

- Customization capabilities to meet specific requirements

- Rigorous quality control processes

- Competitive pricing and flexible ordering options

- Global shipping and support

- Comprehensive technical assistance and after-sales service

- Commitment to innovation and continuous improvement

Material:

Our oil impregnated bronze washers are typically manufactured using high-quality bronze alloys such as C86300 or C93200. These materials offer an excellent balance of strength, wear resistance, and self-lubricating properties. We can also work with custom alloys to meet specific application requirements.

Product Advantages:

- Self-Lubrication: The oil-impregnated structure ensures continuous lubrication, reducing the need for external lubrication and minimizing maintenance requirements.

- Low Friction: Our washers maintain a low coefficient of friction, even under high loads, resulting in smoother operation and reduced energy consumption.

- Wear Resistance: The combination of high-quality bronze alloys and impregnated oil provides exceptional wear resistance, extending the lifespan of both the washer and the mating components.

- Temperature Stability: These washers maintain their performance across a wide temperature range, making them suitable for diverse operating environments.

- Load Capacity: Our products offer excellent load-bearing capabilities, handling both radial and thrust loads efficiently.

- Dimensional Stability: The washers maintain their shape and size even under challenging conditions, ensuring consistent performance over time.

- Corrosion Resistance: The bronze material provides inherent corrosion resistance, making these washers suitable for use in various environments.

Application Areas:

- Automotive Industry: Used in suspension systems, steering mechanisms, and transmission components.

- Aerospace: Found in landing gear assemblies, control surfaces, and cabin interior fittings.

- Industrial Machinery: Applied in conveyor systems, printing presses, and packaging equipment.

- Agricultural Equipment: Utilized in tractors, harvesters, and irrigation systems.

- Marine Applications: Used in deck equipment, propeller shafts, and steering systems.

- Construction Equipment: Found in excavators, cranes, and concrete pumps.

- Material Handling: Applied in forklifts, pallet jacks, and automated storage systems.

- Renewable Energy: Used in wind turbines, solar tracking systems, and hydroelectric equipment.

- Food Processing: Found in mixers, conveyors, and packaging machinery.

- Textile Machinery: Applied in spinning frames, weaving looms, and knitting machines.

- HVAC Systems: Used in compressors, fans, and damper mechanisms.

- Medical Equipment: Found in hospital beds, imaging machines, and surgical tools.

- Robotics and Automation: Applied in robotic arms, linear actuators, and assembly line equipment.

Quality Control:

We implement rigorous quality control measures throughout our production process.

Factory related:

Provide suitable bearing products and supporting services according to the needs of different customers

Packaging and Transportation:

We ensure secure packaging and reliable shipping for all orders.

Shipping Samples:

Sample orders are available for testing and evaluation.

Qualification Certification:

We hold ISO 9001 certification for quality management.

Production process related:

Select appropriate raw materials to produce bearing products that meet technical requirements

Exhibitions:

We regularly participate in international trade shows to showcase our products.

FAQ:

Q: What is the typical lead time for the products?

A: Our standard lead time is 2-3 weeks, but we can accommodate rush orders when needed.

Q: Can you produce custom sizes and designs?

A: Yes, we offer customization services to meet specific application requirements.

Q: What is the minimum order quantity?

A: Our minimum order quantity varies depending on the product specifications. Please contact us for details.

Q: Do you offer technical support for product selection?

A: Absolutely. Our engineering team is available to assist you in choosing the right product for your application.

Q: What are the payment terms?

A: We accept various payment methods, including T/T, L/C, and PayPal. Terms can be discussed based on order specifics.

Contact Us:

For more information about our oil impregnated bronze washers or to discuss your specific needs, please contact us at info@wingold.cc. Our team of experts is ready to assist you in finding the perfect sliding bearing solution for your application.

Learn about our latest products and discounts through SMS or email