- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

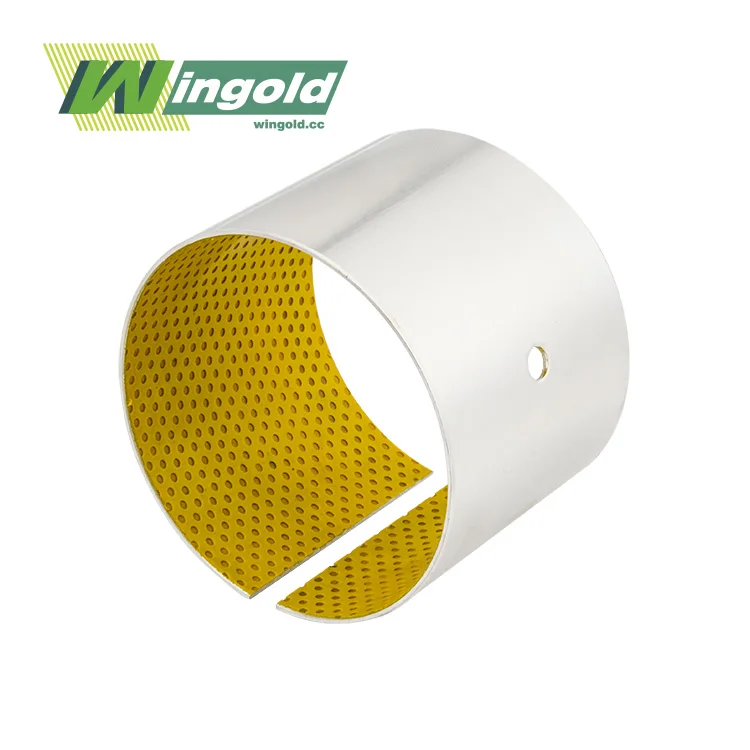

Metric Steel Sleeve Bushings

Metric Steel Sleeve Bushings: Precision-Engineered Solutions for Your Industrial Needs

Jiashan Wingold Bearing Co., Ltd. is a leading manufacturer and supplier of high-quality metric steel sleeve bushings. With our state-of-the-art manufacturing facilities and expert engineering team, we deliver precision-engineered solutions that exceed industry standards. Our products are renowned for their superior durability, tight tolerances, and exceptional performance across various applications.

Metric Steel Sleeve Bushings Introduction

Our metric steel sleeve bushings are designed to provide optimal performance in demanding industrial environments. Crafted from premium-grade steel, these bushings offer exceptional strength, wear resistance, and load-bearing capacity. The precision-machined surfaces ensure smooth operation and minimal friction, extending the lifespan of your equipment and reducing maintenance costs.

We offer a comprehensive range of sizes to meet diverse application requirements, with inner diameters ranging from 5mm to 500mm and outer diameters from 8mm to 600mm. Our bushings feature a cylindrical outer surface and a straight inner bore, making them ideal for applications requiring precise shaft alignment and support.

Specifications:

| Feature | Description |

|---|---|

| Material | High-grade steel alloys |

| Inner Diameter | 5mm - 500mm |

| Outer Diameter | 8mm - 600mm |

| Length | Custom lengths available |

| Surface Finish | Ra 0.2 - 0.8 μm |

| Tolerance | ISO f7/H7 standard (custom tolerances available) |

| Operating Temperature | -40°C to 120°C |

Why Choose Us?

- Over 20 years of industry experience

- ISO 9001:2015 certified quality management system

- Custom solutions tailored to your specific needs

- Competitive pricing and bulk order discounts

- Rapid prototyping and short lead times

- Comprehensive technical support and after-sales service

- Global shipping capabilities

Material:

Our metric steel sleeve bushings are manufactured using high-grade steel alloys, carefully selected for their superior mechanical properties. We also offer custom material options to meet specific application requirements.

Product Advantages:

- Precision Engineering: Our bushings are manufactured to tight tolerances, ensuring a perfect fit and optimal performance in your applications. The precision-machined surfaces minimize friction and wear, extending the lifespan of both the bushing and the mating components.

- Versatility: With a wide range of sizes and customization options, our products can be tailored to suit various industrial applications, from automotive to heavy machinery.

- Load Bearing Capacity: The high-strength steel construction allows our bushings to withstand heavy loads and challenging operating conditions, making them ideal for demanding industrial environments.

- Corrosion Resistance: Our bushings can be treated with various surface finishes to enhance their corrosion resistance, ensuring longevity even in harsh environments.

- Cost-Effective: The durability and long service life of our products translate to reduced maintenance costs and improved equipment uptime, offering excellent value for your investment.

Application Areas:

- Automotive Industry: Suspension systems, steering mechanisms, and powertrain components

- Construction Equipment: Hydraulic cylinders, boom arms, and articulation joints

- Agricultural Machinery: Tractor linkages, harvester mechanisms, and irrigation systems

- Material Handling: Forklift masts, conveyor systems, and crane components

- Aerospace: Landing gear assemblies, flight control mechanisms, and cargo loading systems

- Marine Applications: Rudder bearings, propeller shaft supports, and deck equipment

- Industrial Machinery: Printing presses, textile machinery, and packaging equipment

- Energy Sector: Wind turbine gearboxes, oil and gas drilling equipment, and power generation systems

- Mining Equipment: Excavator boom pivots, crusher bearings, and conveyor idlers

- Railway Industry: Bogie systems, door mechanisms, and pantograph assemblies

Quality Control:

We implement rigorous quality control measures throughout our production process.

Factory related:

Provide suitable bearing products and supporting services according to the needs of different customers

Packaging and Transportation:

We ensure secure packaging and reliable shipping for all orders.

Shipping Samples:

Sample orders are available for testing and evaluation.

Qualification Certification:

We hold ISO 9001 certification for quality management.

Production process related:

Select appropriate raw materials to produce bearing products that meet technical requirements

Exhibitions:

We regularly participate in international trade shows to showcase our products.

FAQ:

Q: What is the minimum order quantity for the products?

A: We offer flexible ordering options, with minimum quantities starting at 100 pieces for standard sizes. For custom orders, please contact our sales team for a tailored quote.

Q: Can you provide custom designs for the products?

A: Absolutely! Our engineering team can work with you to develop custom solutions that meet your specific requirements.

Q: What is the typical lead time for standard products?

A: For standard sizes, our lead time is typically 2-3 weeks. Custom orders may require additional time depending on complexity.

Q: Do you offer any warranty on your products?

A: Yes, we provide a 12-month warranty against manufacturing defects for all our standard products.

Q: Can I request material certifications for the bushings?

A: Certainly! We can provide material certifications and quality documentation upon request.

Contact Us:

Ready to elevate your industrial applications with our premium metric steel sleeve bushings? Contact our expert team today at info@wingold.cc for personalized assistance and quotes. Let's work together to find the perfect bearing solution for your needs!

Learn about our latest products and discounts through SMS or email