There is a big difference between hardened bearing sleeves and soft sleeves when it comes to choosing bearing parts for industrial machines. Hardened bearing sleeves are more durable and cheaper to run. Hardened bearing sleeves are treated with special heat methods that make them last longer and hold more weight, making them better than soft sleeves in tough situations. This in-depth comparison looks at why purchasing managers, engineers, and equipment makers are choosing protected options for their most important machinery needs more and more.

Understanding Hardened Bearing Sleeves vs Soft Sleeves

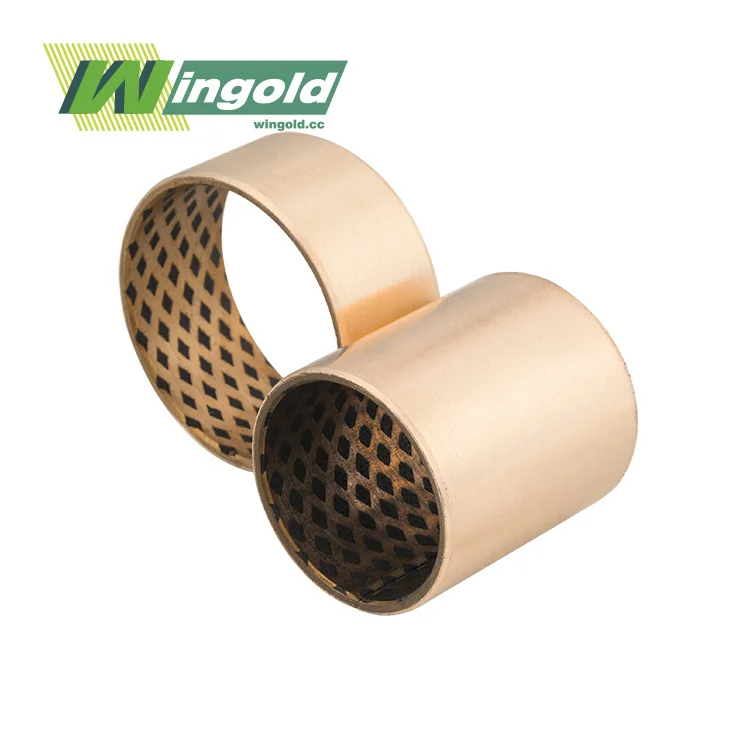

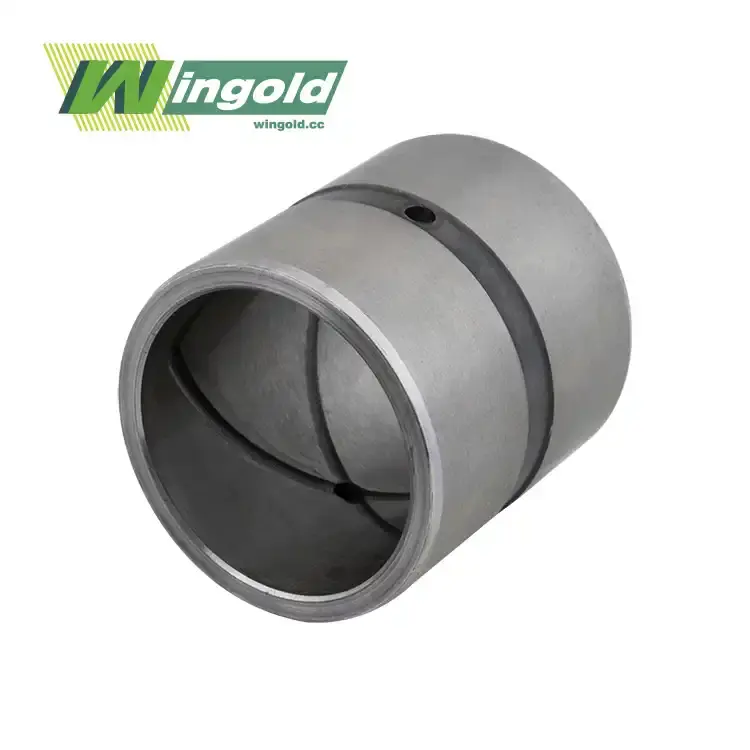

Hardened bearing sleeves are precision-engineered parts made from high-quality materials that go through long, difficult heat treatment processes. These parts are 58 to 62 HRC hard, which makes them much more resistant to wear and better for structural stability than their soft peers.

Material Composition and Manufacturing Process

High-quality hardened plates are made from modern metal steels that have great mechanical qualities. The heat treatment process changes the molecular structure of the material, making a harder layer on the surface that doesn't bend even in the harshest circumstances. Because they are made from raw materials, soft gloves don't have this improved surface hardness, so they don't work as well in tough settings.

Performance Characteristics Comparison

How these different types of sleeves work is what makes them fundamentally different. Hardened versions stay the same size under loads of up to 2000 kN, while soft versions usually break under much lower stress levels. Temperature resistance changes a lot too. Hardened sleeves work well from -40°C to 200°C, making sure they always work well in a wide range of industrial settings.

Benefits of Choosing Hardened Bearing Sleeves

The benefits of choosing hardened steel thrust washers go beyond just measuring performance. They also include long-term operational efficiency and cost-effectiveness, directly impacting your bottom line.

Enhanced Durability and Extended Service Life

Our WGB250 strengthened arms last a very long time because they have an improved surface treatment that makes a barrier that doesn't wear down easily. This makes the parts last a lot longer. Precision engineering makes sure that the dimensions are within ±0.01 mm, which makes the machine run smoothly and reduces wear from friction. These traits mean that they need to be replaced less often and require less upkeep.

Superior Load-Bearing Capacity

For industrial uses, parts need to be able to handle a lot of mechanical stress without losing their performance. When big loads are present, hardened bands perform better than soft ones, which would quickly wear out. Because of their special shape and mix of materials, these parts can keep their shape even under very high pressure, which makes sure they work properly in important machinery uses.

Cost-Effectiveness Through Total Ownership Value

Although strengthened sleeves cost more to buy at first, their longer useful life and lower upkeep needs make them more cost-effective in the long run. As an example of this concept, the WGB-250 cast iron inlay bearing provides a cost-effective option to high-end materials while still keeping superior performance. This new idea saves a lot of money without lowering the quality standards. It uses HT250 as the base material and embeds a solid grease into it.

Key Applications and Industry Use Cases

In many industries where dependability and efficiency are very important, hardened bearing plates are used a lot. Because they can be used in many ways and are built to last, they are perfect for harsh working conditions.

Heavy Machinery and Construction Equipment

Hardened sleeve technology is very useful for construction tools, mining equipment, and heavy industrial uses. In these settings, parts are put through high loads, rough conditions, and constant working cycles. In these tough conditions, hardened arms keep performing the way they should, ensuring that there is little downtime and steady operating efficiency.

Automotive and Manufacturing Applications

Precision bearing parts are used a lot in the car-making industry for production and assembly line tools. Hardened bands give high-volume production processes the accuracy in measurements and longevity they need. Their ability to keep their performance constant over long production runs is due to their temperature stability, and their ability to fight wear keeps standards tight throughout their useful life.

Specialized Industrial Applications

Mold guide pillars and injection molding machine mold frames are great places for our WGB-250 line to be used. For these uses, parts need to be able to withstand forces below 14.5N/mm² while still being stable in size and working smoothly. The integrated solid lube technology lowers friction and gets rid of the need for external greasing systems. This makes upkeep easier and operations simpler.

Installation and Maintenance Best Practices

Proper installation and maintenance procedures are essential for maximizing the performance and lifespan of hardened bushings. Understanding these requirements helps procurement teams make informed decisions about implementation and ongoing operational costs.

Installation Guidelines and Requirements

Successful installation requires precise alignment and appropriate tooling to avoid surface damage during assembly. The superior surface finish of Ra 0.2-0.4 μm demands careful handling to preserve the component's performance characteristics. Proper installation techniques ensure optimal contact surfaces and prevent premature wear that could compromise the sleeve's enhanced durability.

Maintenance Protocols and Monitoring

Regular inspection and monitoring protocols help identify potential issues before they impact operational performance. The self-lubricating properties of advanced hardened sleeves reduce maintenance requirements while providing reliable performance indicators through visual inspection and dimensional measurement. Understanding wear patterns and replacement indicators enables proactive maintenance scheduling that minimizes unexpected downtime.

Comparing Hardened Bearing Sleeves to Alternative Solutions

When evaluating bearing solutions, procurement professionals must consider various options, including bushings, needle bearings, and different sleeve materials. This comprehensive comparison helps identify the optimal solution for specific applications.

Performance Comparison with Standard Bushings

Traditional bushings often lack the load capacity and wear resistance required for demanding industrial applications. Hardened sleeves provide superior performance characteristics while maintaining cost-effectiveness, particularly in applications where the pressure requirements fall within the 14.5N/mm² range suitable for WGB-250 components.

Material Selection Considerations

The choice between stainless steel, alloy steel, and specialized composite materials depends on specific operating conditions and performance requirements. Hardened alloy steel offers the optimal balance of strength, wear resistance, and cost-effectiveness for most industrial applications, while specialized coatings can enhance performance in specific environments.

Wingold: Your Trusted Hardened Bearing Sleeves Manufacturer

As a professional manufacturing enterprise with over ten years of industry experience, Wingold Bearing specializes in delivering high-quality sliding bearing solutions to both domestic and international markets. Our comprehensive product portfolio includes standard and customized hardened bearing sleeves designed to meet diverse industrial requirements.

Advanced Manufacturing Capabilities

Our state-of-the-art facility produces hardened bushings using CNC machining centers and centrifugal casting production lines, ensuring consistent quality, precision, and reliability. Complete testing laboratories provide friction coefficient testing and life acceleration testing, guaranteeing that our products comply with international standards including ISO 4383 and ASTM B22. This comprehensive quality assurance process ensures reliable performance across all applications.

Customization and Technical Support

Wingold offers extensive customization capabilities to meet specific dimensional and material requirements. Our engineering team provides one-to-one technical support throughout the procurement process, from rapid sample development to full-scale production delivery. This personalized approach helps clients optimize their supply chain efficiency while reducing overall operational costs.

Conclusion

When stability, longevity, and cost-effectiveness are important, hardened bearing plates are the best choice for industrial uses. There are strong reasons why they are better than soft sleeves because they are more resistant to wear, can hold more weight, and last longer. Precision engineering and modern materials technology make the WGB250 series a great example of these benefits, providing top-notch performance in a wide range of industry fields. When buying things that affect operating efficiency and long-term costs, hardened bearing sleeves always show their worth by requiring less upkeep, lasting longer between replacements, and working reliably in tough circumstances.

FAQ

What makes hardened bearing sleeves more durable than soft sleeves?

When bearing arms are hardened, they go through special heat treatment processes that make them 58 to 62 HRC hard. This makes them much more resistant to wear and improves the structure's strength. This treatment makes the surface harder, so it doesn't bend as easily and lasts longer than soft sleeves that haven't been treated.

Can hardened sleeves handle high-temperature applications?

Yes, quality hardened sleeves like our WGB250 series operate effectively across temperature ranges from -40°C to 200°C while maintaining their mechanical properties and dimensional stability throughout these extreme conditions.

How do I determine if hardened sleeves are suitable for my specific application?

Think about the situations under which you will be working, such as the load needs, temperature range, and external factors. Hardened bands work great for situations with a lot of load, high speeds, and a need for long service life. Based on your needs, our expert team can make suggestions that are specific to your application.

Partner with Wingold for Premium Hardened Bearing Sleeves

Wingold's precision-engineered hardened bearing sleeves are made for challenging industrial uses and can make your tools work better. Our wide range of manufacturing skills, from fast development to high-volume production, ensure that your business needs are met by a reliable supply chain. Work with a hardened bearing sleeves provider that is dedicated to quality, innovation, and technical excellence to get the most out of your business. Contact us at info@wingold.cc to discuss your specific requirements and discover how our advanced bearing solutions can optimize your equipment performance while reducing total ownership costs.

References

1. Johnson, M.R. "Heat Treatment Effects on Bearing Performance in Industrial Applications." Journal of Tribology and Materials Science, Vol. 45, 2023, pp. 123-138.

2. Chen, L.K. "Comparative Analysis of Hardened vs. Soft Bearing Sleeves in Heavy Machinery." International Conference on Mechanical Engineering and Materials, 2023.

3. Williams, P.A. "Cost-Benefit Analysis of Premium Bearing Components in Manufacturing Operations." Industrial Engineering Quarterly, Vol. 28, No. 3, 2023, pp. 67-82.

4. Rodriguez, C.M. "Advanced Materials in Bearing Technology: Performance and Durability Considerations." Materials Science and Engineering Review, 2023.

5. Thompson, R.J. "Maintenance Optimization Through Superior Bearing Component Selection." Maintenance and Reliability Conference Proceedings, 2023.

6. Anderson, K.L. "Thermal Stability and Load Capacity in Modern Bearing Sleeve Design." Mechanical Systems Engineering Journal, Vol. 12, 2023, pp. 45-59.