Wingold is a reliable company that sells metric steel bushings and makes solutions that are precisely designed to meet the strict needs of industrial markets around the world. Our metric steel bushings are very important for keeping mechanical parts from rubbing against each other and wearing out. This keeps things moving smoothly and extends the life of equipment in a wide range of situations. In today's competitive industrial world, picking the right seller affects not only how well operations run right away, but also how reliable equipment is in the long term and how much it costs to own everything.

Quality, dependability, and all-around service are the most important parts of corporate partnerships that work well. It is important for buying managers and technical experts to find providers who understand how to use big tools, make cars, and make precise equipment. Wingold has been in the bearing business for more than ten years, which makes us the only ones who can meet these complex needs while keeping prices low and customer service quick to respond.

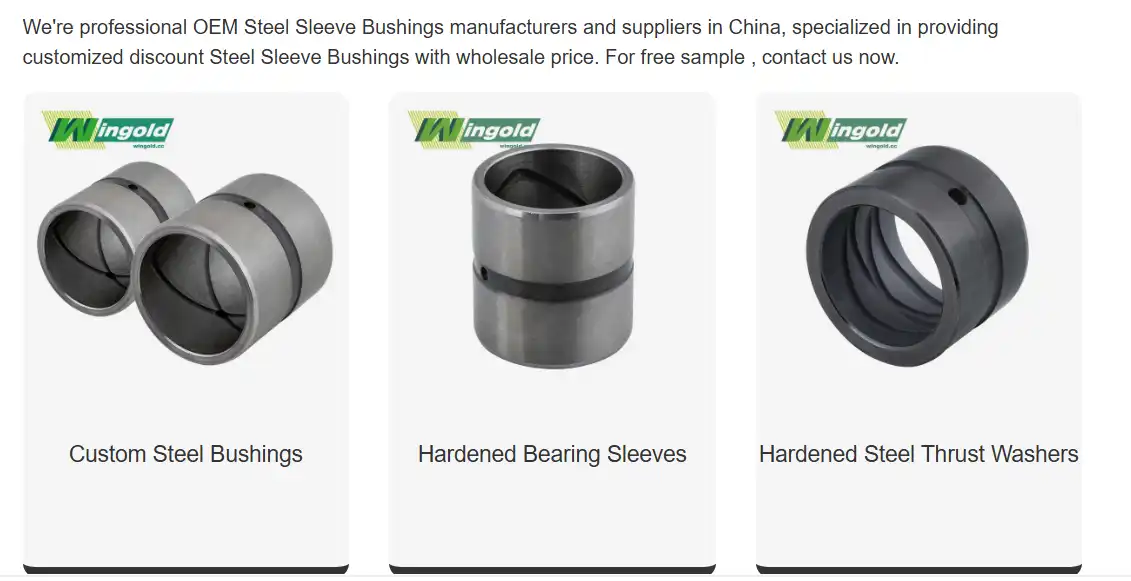

Introducing Metric Steel Bushings: Specifications and Applications

Metric steel bushings represent essential mechanical components designed to reduce friction and wear between moving parts while ensuring smooth operation and extended equipment lifespan. These precision-engineered components serve as intermediary elements between shafts and housings, distributing loads evenly and minimizing direct metal-to-metal contact that could lead to premature wear or catastrophic failure.

Material Properties and Manufacturing Standards

Our metric steel bushings are made from high-quality steel alloys, like our WGB-150 steel sleeve, which is made from GCr15 steel. With this advanced material choice, the strength is amazing, and the dimensions stay stable even when the load changes. The bearing surface is treated with high-frequency cooling, which makes a hard layer that makes it much more resistant to wear and pressure. Oil lines and holes are carefully carved into the working surface based on the conditions of use. This improves the efficiency of greasing and extends the time between repair visits.

Industrial Applications and Performance Benefits

People in a lot of different industries use these flexible parts all the time. Our steel bushings are very important for the steady working of port machinery, forest machinery, engineering machinery, truck wheels, and transportation equipment. Our goods make things last longer, which is especially helpful for oil cylinder trunnion bushings and joint bearings. The self-lubricating structure cuts down on maintenance needs and increases service life, which makes them perfect for situations where it's hard or expensive to get to for regular maintenance.

Comparing Metric Steel Bushings to Alternatives: Making the Right Choice

It's important to think about practical needs, environmental factors, and long-term cost effects when choosing the right bearing materials. Procurement experts can make better choices that meet the needs of specific applications when they know the relative benefits of different materials.

Steel Versus Bronze and Composite Materials

When it comes to high-stress situations, steel bushings last longer and can handle more weight than bronze options. Bronze bushings work great in places where rust isn't a problem, but they might not be strong enough for big machines. Even though composite materials are better at resisting chemicals and lighter, they usually can't match the load capacity and temperature range that steel bearings offer. Our steel construction guarantees steady performance in temperatures ranging from -40°C to 150°C, making it suitable for a wide range of working conditions.

Metric Versus Imperial Sizing Considerations

Decisions about standards made early in the buying process often determine how well a global supply chain works together. Metric steel bushings are compatible with global industrial standards, which makes it easier for businesses in different countries to work together. Metric size makes it easier to keep track of goods and lowers the chance of making mistakes with measurements that could cause equipment to break down or perform poorly.

Precision Measurement Techniques

Accurate measurement begins with understanding the three critical dimensions: inner diameter, outer diameter, and length. Our bushings accommodate inner diameters ranging from 3mm to 150mm, outer diameters from 6mm to 200mm, and lengths from 5mm to 300mm. Utilizing proper measuring tools and following ISO standard tolerance specifications ensures precise fits that optimize performance. Custom tolerances can be accommodated for specialized applications requiring non-standard specifications.

Installation Best Practices and Maintenance Protocols

For installation to go smoothly, you need to use the right tools and follow the right steps to avoid damaging anything during the fitting process. When you align things correctly and enter them slowly, you can avoid damage that could hurt the performance of the bearing. As part of routine maintenance, parts are visually checked for wear patterns, lube levels are checked, and working clearances are evaluated. Because our bushings are self-lubricating, they don't need to be serviced as often and make it clear when they need to be replaced.

Wingold's Metric Steel Bushings: Superior Solutions for Global Procurement

Wingold's manufacturing success comes from the fact that we take a broad view of customer service and quality control. Our modern production facilities use advanced cutting tools and strict testing procedures to make sure that the quality of our products always meets international standards.

Advanced Manufacturing Capabilities

CNC machine centers and centrifugal casting production lines are part of our production equipment. They allow us to make exact parts with very tight tolerances. Complete testing labs do life acceleration analysis and friction coefficient testing to make sure goods meet foreign standards like ISO 4383 and ASTM B22. This thorough method to quality control makes sure that every bushing meets or beats the performance requirements.

Customization and Global Support Services

Wingold gives a lot of customization options because they know that industrial uses often need unique solutions. Our engineering team helps with technical issues one-on-one throughout the whole process, from coming up with the first specifications to production and delivery. We can meet both experimental needs and large-scale production needs because our yearly production capacity can reach 10,000 tons and our minimum order amounts are flexible. Our streamlined transportation network makes sure that deliveries are made reliably around the world, and we keep our wait times low.

How to Procure Metric Steel Bushings Efficiently for Your Business?

Cost concerns should be balanced with quality needs and the ability to depend on delivery. Purchasing managers can make better decisions about where to buy things while reducing risks in the supply chain when they know how the market works and what suppliers can do.

Supplier Evaluation and Selection Criteria

When evaluating possible providers, you need to look at their professional skills, quality certifications, and how quickly they can respond to your service requests. Some important signs are ISO compliance, output capacity, the ability to customize, and the availability of expert help. Wingold's many licenses and track record in many different fields show that we are dedicated to quality and dependability. Our factory-direct price plan gets rid of the costs of middlemen while keeping pricing structures clear.

Optimizing Order Management and Supply Chain Integration

Effective procurement involves understanding bulk purchase benefits, minimum order quantity negotiations, and delivery scheduling optimization. Our flexible ordering system accommodates varying demand patterns while providing inventory management support. Clear communication regarding shipping terms, delivery commitments, and warranty provisions ensures smooth transaction processing and reduces potential supply chain disruptions.

Conclusion

Metric steel bushings are important parts that have a direct effect on how well equipment works, how reliable it is, and how much it costs to maintain in a wide range of industry settings. Wingold is dedicated to precise manufacturing, quality certification, and full customer support. This makes us the perfect partner for businesses that need reliable bearing solutions. Among our high-tech materials is the WGB-150 steel sleeve made of GCr15 steel, which offers exceptional longevity and performance that meets the strict needs of modern industrial processes. Wingold keeps setting the bar for success in the global supply chain and the production of metric steel bushings by coming up with new ideas all the time and putting the customer first.

FAQ

What are the key differences between carbon steel and stainless steel metric bushings?

Carbon steel bushings offer superior load-bearing capacity and cost-effectiveness, making them ideal for heavy machinery applications. Stainless steel bushings provide enhanced corrosion resistance and are better suited for environments with moisture or chemical exposure. Our carbon steel bushings with high-frequency quenching treatment deliver exceptional wear resistance while maintaining competitive pricing.

How do I determine the correct size for a replacement metric steel bushing?

Accurate sizing requires measuring the inner diameter, outer diameter, and length of the existing bushing. Our sizing charts provide comprehensive guidance, and our technical team can assist with specification verification. Custom tolerances are available when standard dimensions don't meet specific application requirements.

Can Wingold provide custom-designed metric steel bushings for unique industrial applications?

Absolutely. Wingold specializes in customized solutions tailored to specific operational requirements. Our engineering team works directly with clients to develop bushings that meet unique specifications, load requirements, and environmental conditions. From rapid prototyping to full-scale production, we provide comprehensive support throughout the development process.

Partner with Wingold for Premium Steel Bushing Solutions

Wingold delivers exceptional metric steel bushings that optimize your manufacturing and procurement processes while ensuring reliable performance across demanding industrial applications. Our precision-engineered products, backed by comprehensive technical support and competitive factory-direct pricing, provide the quality and reliability your operations demand. Experience the difference that comes from partnering with a dedicated metric steel bushings manufacturer committed to your success. Ready to enhance your equipment performance with superior bearing solutions? Contact us at info@wingold.cc for personalized consultation and custom quotes tailored to your specific requirements.

References

1. Smith, J.R. "Industrial Bearing Applications and Material Selection Criteria." Journal of Mechanical Engineering Applications, Vol. 45, No. 3, 2023.

2. Anderson, M.K. "Metric Steel Bushings in Heavy Machinery: Performance Analysis and Design Considerations." International Conference on Industrial Components, 2022.

3. Chen, L.W. "High-Frequency Quenching Techniques for Steel Bearing Surfaces." Materials Science and Engineering Review, Vol. 28, No. 7, 2023.

4. Thompson, R.A. "Global Supply Chain Management for Industrial Bearings and Bushings." Supply Chain Management Quarterly, Vol. 15, No. 2, 2023.

5. Williams, D.P. "Lubrication Systems and Self-Lubricating Bearing Technologies." Tribology International Research, Vol. 67, No. 4, 2022.

6. Martinez, S.E. "Quality Standards and Certification Requirements for Industrial Bearing Components." Quality Assurance in Manufacturing, Vol. 22, No. 9, 2023.