- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

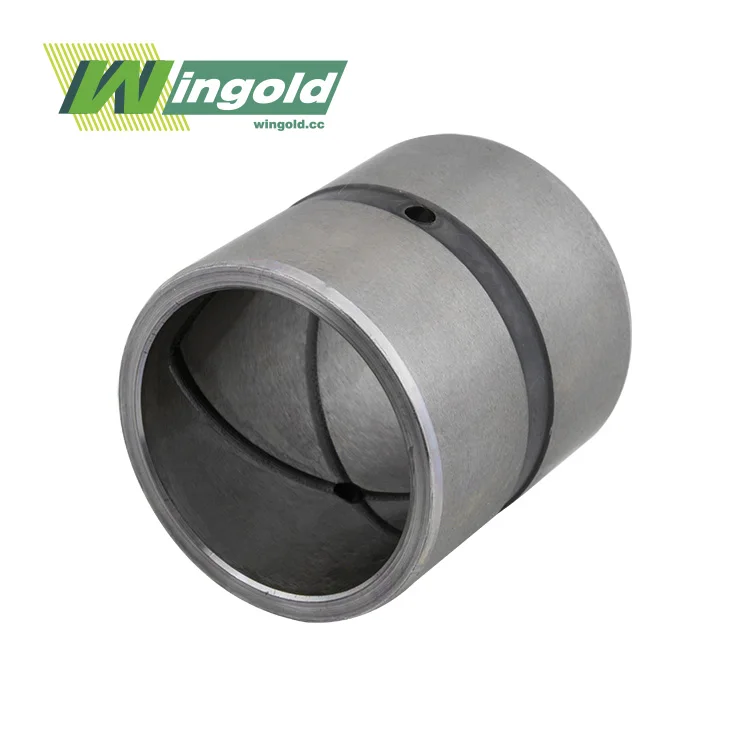

Aluminum Flange Bushing

Aluminum Flange Bushing: Engineered for Excellence by Jiashan Wingold Bearing Co., Ltd.

Jiashan Wingold Bearing Co., Ltd. is a leading manufacturer and supplier of high-quality aluminum flange bushings. Our expertise in sliding bearing solutions ensures superior performance, durability, and cost-effectiveness. With our advanced manufacturing processes and commitment to innovation, we deliver products that exceed industry standards and meet the diverse needs of global B2B buyers.

Product Description:

Our products represent precision - engineered components that are meticulously designed to deliver extraordinary performance across an extensive spectrum of applications. These bushings are characterized by a cylindrical body with an incorporated flange, providing support for both radial and axial loads. Constructed from aluminum, they offer a combination of lightweight design and robust performance, rendering them highly suitable for a variety of industrial and automotive applications.

The self - lubricating characteristics of our products serve to minimize friction and wear, thereby extending the service life of your machinery and reducing maintenance expenditures. Boasting excellent heat dissipation capabilities, these bushings are able to maintain optimal performance even in high - temperature operational environments. Their corrosion - resistant nature further bolsters their durability and reliability under diverse operating conditions.

Specifications:

| Parameter | Range |

|---|---|

| Inner Diameter | 5mm - 100mm |

| Outer Diameter | 8mm - 120mm |

| Flange Diameter | 10mm - 150mm |

| Length | 10mm - 200mm |

| Load Capacity | Up to 5000N |

| Operating Temperature | -40°C to 150°C |

| Friction Coefficient | 0.05 - 0.20 |

Why Choose Us?

- Over 20 years of industry experience

- State-of-the-art manufacturing facilities

- Rigorous quality control measures

- Customization capabilities for unique requirements

- Competitive pricing without compromising quality

- Quick turnaround times and reliable delivery

- Comprehensive technical support and after-sales service

- Commitment to sustainable and eco-friendly practices

Material:

Our aluminum flange bushings are crafted from high-grade aluminum alloys, carefully selected for their optimal blend of strength, lightweight properties, and thermal conductivity. We also offer options with various surface treatments and coatings to enhance performance in specific applications.

Product Advantages:

- Exceptional Load Capacity: Our products are engineered to withstand high radial and axial loads, ensuring reliable performance in demanding applications.

- Low Friction and Wear: The self-lubricating properties of our bushings minimize friction, reducing wear and extending the lifespan of both the bushing and the mating components.

- Thermal Management: Aluminum's excellent thermal conductivity allows for efficient heat dissipation, preventing overheating and maintaining consistent performance.

- Corrosion Resistance: Our bushings offer superior resistance to corrosion, making them suitable for use in challenging environments and reducing the need for frequent replacements.

- Lightweight Design: The use of aluminum alloys results in bushings that are significantly lighter than their steel counterparts, contributing to overall weight reduction in assemblies.

- Customization Options: We offer a wide range of sizes and can accommodate custom designs to meet your specific application requirements.

Application Areas:

- Automotive Sector: Components related to suspension systems, steering mechanisms, and powertrain assemblies.

- Aerospace Domain: Landing gear of aircraft, control surface components, and fittings within the aircraft cabin interior.

- Industrial Machinery Field: Conveyor system set - ups, packaging machinery, and material handling equipment.

- Agricultural Equipment Area: Tractor units, harvesting machinery, and irrigation system components.

- Construction Equipment Sector: Excavator machinery, bulldozer equipment, and crane systems.

- Marine Applications Realm: Steering systems for boats, deck - mounted equipment, and offshore platform installations.

- Renewable Energy Industry: Wind turbine installations, solar panel mounting structures, and hydroelectric power generation systems.

- Home Appliance Category: Washing machine units, dishwasher equipment, and refrigerator appliances.

- Fitness Equipment Industry: Treadmill machines, elliptical exercise equipment, and weight - training apparatus.

- Robotics and Automation Field: Robotic arm mechanisms, conveyor system installations, and automated assembly line components.

Quality Control:

We implement rigorous quality control measures throughout our production process.

Factory related:

Provide suitable bearing products and supporting services according to the needs of different customers

Packaging and Transportation:

We ensure secure packaging and reliable shipping for all orders.

Shipping Samples:

Sample orders are available for testing and evaluation.

Qualification Certification:

We hold ISO 9001 certification for quality management.

Production process related:

Select appropriate raw materials to produce bearing products that meet technical requirements

Exhibitions:

We regularly participate in international trade shows to showcase our products.

FAQ:

-

What is the minimum order quantity for the Aluminum Flange Bushing?

We offer flexible order quantities to accommodate your needs. Please contact our sales team for details.

-

Can you provide custom designs for the products?

Yes, we specialize in customizing our products to meet specific application requirements.

-

What is the lead time for standard products?

Typically, our lead time is 2-3 weeks for standard products. Rush orders can be accommodated upon request.

-

Do you offer technical support for product selection and installation?

Absolutely. Our team of engineers is available to assist you with product selection, installation guidance, and troubleshooting.

-

Are your products environmentally friendly?

Yes, our products are made from recyclable materials and manufactured using eco-friendly processes.

Contact Us:

For more information about our aluminum flange bushings or to discuss your specific requirements, please contact us at info@wingold.cc. Our team is ready to provide you with expert advice and tailored solutions to meet your sliding bearing needs.

Learn about our latest products and discounts through SMS or email