- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

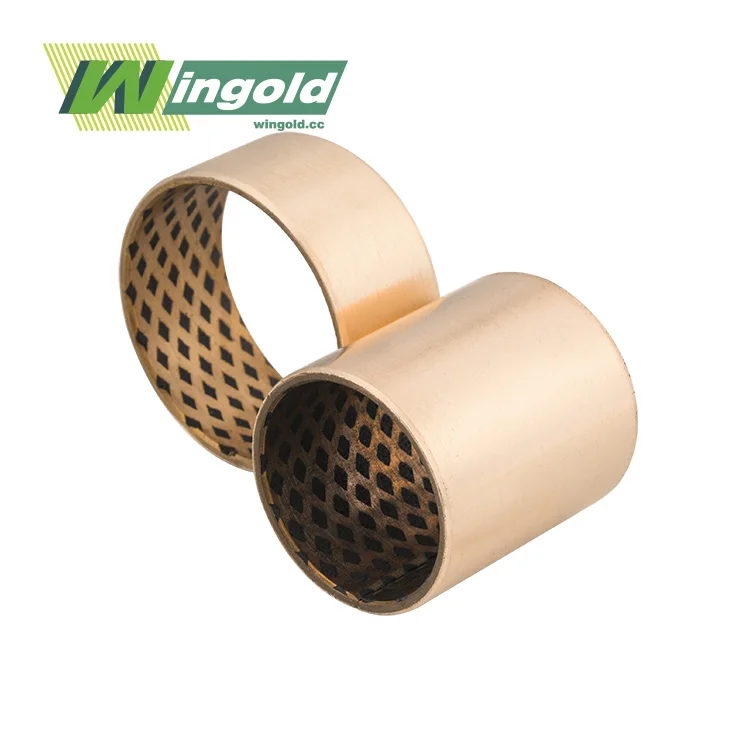

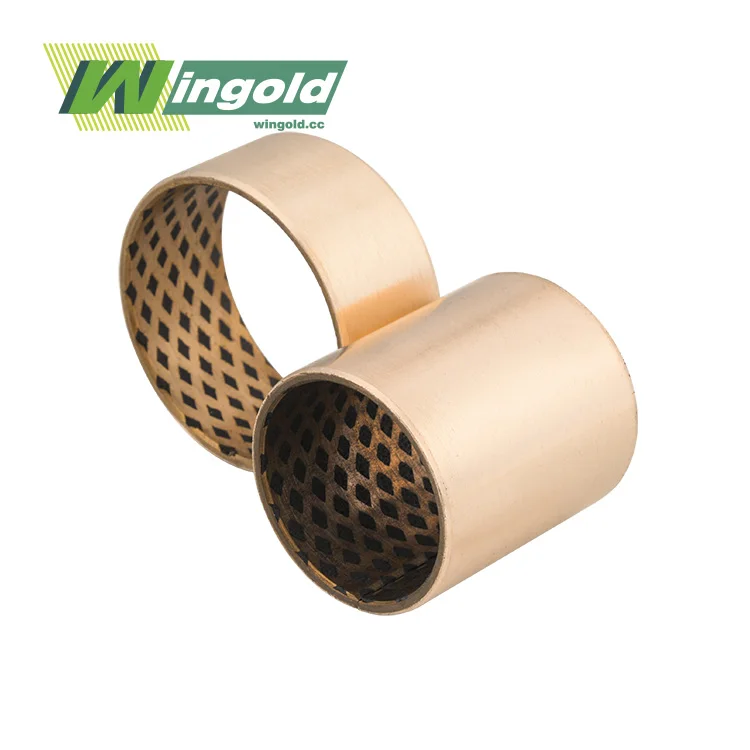

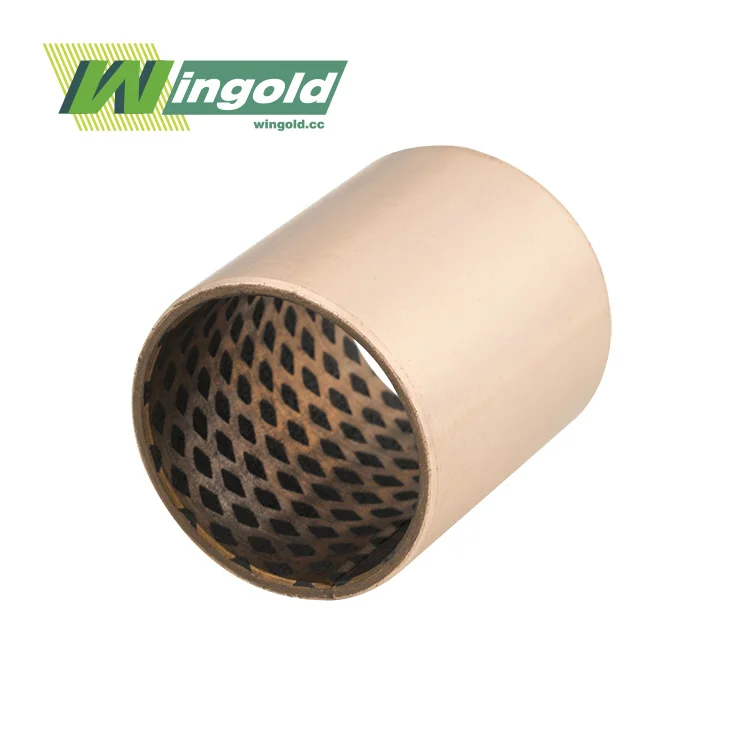

Oil Impregnated Bronze Bearings

Oil Impregnated Bronze Bearings: Superior Performance and Reliability

Jiashan Wingold Bearing Co., Ltd. is a leading manufacturer and supplier of oil impregnated bronze bearings. Our expertise in sliding bearing solutions ensures superior quality, reliability, and performance. With advanced manufacturing techniques and rigorous quality control, Wingold's products offer exceptional durability, low friction, and self-lubricating properties, making them the ideal choice for various industrial applications.

Oil Impregnated Bronze Bearings Introduction

Our oil impregnated bronze bearings are engineered to deliver outstanding performance in demanding environments. These bearings are manufactured using high-quality bronze alloys and impregnated with specially formulated lubricating oil. The porous structure of the bronze allows the oil to be retained within the bearing, providing continuous lubrication during operation.

The oil impregnation process ensures that these bearings offer excellent self-lubricating properties, reducing the need for frequent maintenance and extending the lifespan of your machinery. Our bearings are designed to operate smoothly under heavy loads and at high speeds, making them suitable for a wide range of applications across various industries.

Specifications:

| Parameter | Value |

|---|---|

| Material | Bronze Alloy (C86300, C93200, or custom) |

| Oil Content | 25-35% by volume |

| Operating Temperature | -20°C to 150°C |

| Maximum PV Value | Up to 1.8 N/mm² • m/s |

| Shaft Hardness | Minimum 35 HRC recommended |

| Available Shapes | Cylindrical, flanged, thrust washers, custom |

| Size Range | ID: 3mm - 300mm, OD: 6mm - 400mm |

| Tolerance Grade | IT7 - IT9 (tighter tolerances available) |

Why Choose Us?

- Over 20 years of industry experience

- Advanced manufacturing facilities

- Customization capabilities to meet specific requirements

- Rigorous quality control processes

- Competitive pricing and flexible order quantities

- Excellent customer support and technical assistance

- Fast turnaround times and reliable delivery

- Commitment to continuous innovation and improvement

Material:

Our oil impregnated bronze bearings are primarily made from high-quality bronze alloys such as C86300 and C93200. These materials offer an excellent combination of strength, wear resistance, and thermal conductivity. The composition can be customized based on specific application requirements to optimize performance.

Product Advantages:

- Self-Lubrication: The oil-impregnated structure provides continuous lubrication, reducing friction and wear without the need for external lubrication systems.

- Low Maintenance: The self-lubricating property significantly reduces maintenance requirements, leading to lower operational costs and increased uptime.

- High Load Capacity: Our bearings can withstand high loads while maintaining smooth operation, making them suitable for demanding industrial applications.

- Excellent Wear Resistance: The combination of high-quality bronze alloys and oil impregnation results in superior wear resistance, extending the lifespan of both the bearing and the mating shaft.

- Wide Temperature Range: These bearings perform reliably across a broad temperature range, from -20°C to 150°C, ensuring consistent operation in various environments.

- Corrosion Resistance: The bronze material offers good resistance to corrosion, making these bearings suitable for use in challenging environments.

- Low Friction: The oil-impregnated surface provides low friction coefficients, reducing energy consumption and heat generation during operation.

Application Areas:

- Automotive Industry: Used in steering systems, suspension components, and transmission assemblies.

- Aerospace: Applied in flight control systems, landing gear, and cabin interior mechanisms.

- Industrial Machinery: Utilized in conveyor systems, printing presses, and packaging equipment.

- Agricultural Equipment: Employed in tractors, harvesters, and irrigation systems.

- Marine Applications: Used in propeller shafts, rudder bearings, and deck equipment.

- Construction Equipment: Applied in excavators, bulldozers, and cranes.

- Material Handling: Utilized in forklifts, pallet jacks, and automated guided vehicles.

- Renewable Energy: Used in wind turbines and solar tracking systems.

- Food Processing Equipment: Applied in mixers, conveyors, and packaging machinery.

- Textile Machinery: Employed in spinning machines, looms, and knitting equipment.

Quality Control:

We implement rigorous quality control measures throughout our production process.

Factory related:

Provide suitable bearing products and supporting services according to the needs of different customers

Packaging and Transportation:

We ensure secure packaging and reliable shipping for all orders.

Shipping Samples:

Sample orders are available for testing and evaluation.

Qualification Certification:

We hold ISO 9001 certification for quality management.

Production process related:

Select appropriate raw materials to produce bearing products that meet technical requirements

Exhibitions:

We regularly participate in international trade shows to showcase our products.

FAQ:

Q: What is the typical lead time for the products?

A: Our standard lead time is 2-3 weeks, depending on the order quantity and specifications.

Q: Can you provide custom sizes and designs?

A: Yes, we offer customization services to meet specific application requirements.

Q: What is the minimum order quantity?

A: Our minimum order quantity varies based on the product type and specifications. Please contact us for details.

Q: Do you offer technical support for product selection and installation?

A: Absolutely. Our team of engineers is available to assist you with product selection, installation guidance, and troubleshooting.

Q: What industries do you primarily serve?

A: We serve a wide range of industries, including automotive, aerospace, industrial machinery, and more.

Contact Us:

For more information about our oil impregnated bronze bearings or to discuss your specific requirements, please contact us at info@wingold.cc. Our team is ready to provide you with expert advice and tailored solutions for your bearing needs.

Learn about our latest products and discounts through SMS or email