- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

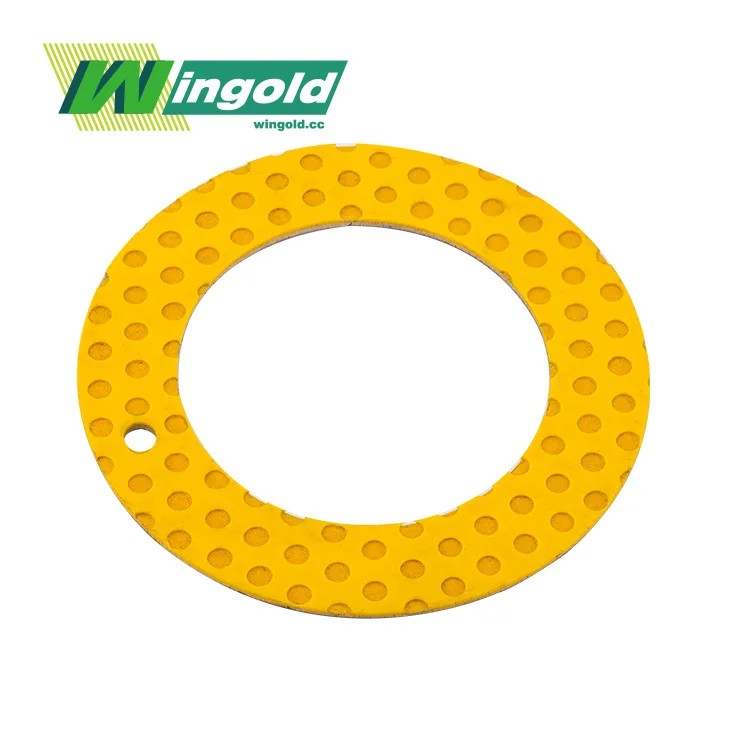

Bronze Self Lubricating Bearing

Bronze Self Lubricating Bearing: Superior Performance for Your Applications

Jiashan Wingold Bearing Co., Ltd. is a leading bronze self lubricating bearing manufacturer and supplier. Our expertise in sliding bearing solutions sets us apart, offering unparalleled quality and reliability. With cutting-edge technology and a customer-centric approach, Wingold's products provide exceptional performance, longevity, and cost-effectiveness for diverse industrial applications.

Product Description:

Our top - tier products are crafted to provide remarkable performance under harsh conditions.These bearings feature a unique composition of high-quality bronze alloy with embedded solid lubricants, ensuring smooth operation and minimal maintenance requirements. The self-lubricating properties eliminate the need for external lubrication, reducing downtime and maintenance costs while enhancing overall system efficiency.

Specifications:

| Parameter | Value |

|---|---|

| Material | Bronze alloy with solid lubricants |

| Load capacity | Up to 140 MPa |

| Temperature range | -40°C to 150°C |

| Friction coefficient | 0.05 - 0.15 |

| Wear rate | < 5 µm/km |

| Size range | 3mm - 300mm (ID) |

| Customization | Available |

Why Choose Us?

- Over 20 years of industry experience

- State-of-the-art manufacturing facilities

- Rigorous quality control processes

- Customization capabilities to meet specific requirements

- Competitive pricing and flexible financial solutions

- Quick turnaround times and reliable global logistics

- Comprehensive technical support and after-sales service

- Commitment to innovation and continuous improvement

Material:

Our products are fabricated using a meticulously chosen bronze alloy, augmented with solid lubricants like graphite or PTFE. This distinctive blend guarantees remarkable wear resistance, minimal friction, and outstanding load - bearing capabilities, rendering them suitable for a diverse array of applications.

Product Advantages:

- Self-Lubrication: The embedded solid lubricants in our bronze bearings provide continuous lubrication throughout their operational life, eliminating the need for external lubrication systems and reducing maintenance costs.

- High Load Capacity: Our bronze self lubricating bearings can withstand high loads while maintaining excellent performance, making them suitable for demanding industrial applications.

- Wide Temperature Range: These bearings operate efficiently across a broad temperature spectrum, from -40°C to 150°C, ensuring reliability in various environmental conditions.

- Low Friction and Wear: The unique material composition results in a low coefficient of friction and minimal wear, extending the bearing's service life and improving overall system efficiency.

- Corrosion Resistance: The bronze alloy offers excellent resistance to corrosion, making these bearings ideal for use in harsh environments or applications exposed to moisture or chemicals.

Application Areas:

- Automotive Industry: Suspension systems, steering mechanisms, and brake components

- Aerospace: Landing gear, flight control systems, and aircraft seating

- Marine Applications: Rudder bearings, propeller shaft bearings, and deck equipment

- Construction Equipment: Excavators, bulldozers, and cranes

- Agricultural Machinery: Tractors, harvesters, and irrigation systems

- Material Handling: Conveyor systems, forklifts, and packaging equipment

- Energy Sector: Wind turbines, hydroelectric power plants, and solar tracking systems

- Industrial Machinery: Textile machinery, printing presses, and injection molding machines

- Food Processing: Mixers, conveyor systems, and packaging equipment

- HVAC Systems: Compressors, fans, and air handling units

Quality Control:

We implement rigorous quality control measures throughout our production process.

Factory related:

Provide suitable bearing products and supporting services according to the needs of different customers

Packaging and Transportation:

We ensure secure packaging and reliable shipping for all orders.

Shipping Samples:

Sample orders are available for testing and evaluation.

Qualification Certification:

We hold ISO 9001 certification for quality management.

Production process related:

Select appropriate raw materials to produce bearing products that meet technical requirements

Exhibitions:

We regularly participate in international trade shows to showcase our products.

FAQ:

- What is the typical lead time for the Bronze Self Lubricating Bearing?

Our standard lead time is 2-3 weeks, but we can accommodate rush orders when needed. - Can you provide custom sizes or designs?

Yes, we offer customization services to meet your specific requirements. - What is the minimum order quantity?

Our minimum order quantity varies depending on the product. Please contact us for details. - Do you offer technical support for bearing selection?

Absolutely! Our engineering team is available to assist you in choosing the right bearing for your application. - What warranty do you provide for your products?

We offer a standard 12-month warranty on our products, with extended options available.

Contact Us:

Ready to experience the superior performance of our bronze self lubricating bearings? Contact us today at info@wingold.cc to discuss your requirements and discover how we can optimize your operations with our cutting-edge bearing solutions.

Learn about our latest products and discounts through SMS or email