- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

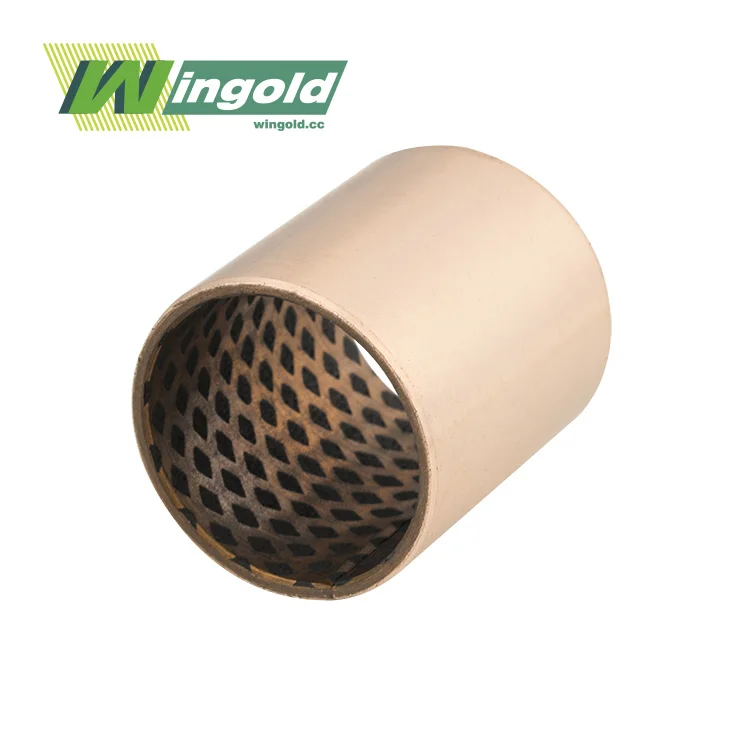

Brass Self Lubricating

Brass Self Lubricating Bearings: High-Performance Solutions for Your Industrial Needs

Jiashan Wingold Bearing Co., Ltd. is a leading manufacturer and supplier of brass self lubricating bearings. With our extensive experience and cutting-edge technology, we offer superior quality bearings that provide exceptional performance, durability, and cost-effectiveness. Our products stand out for their excellent load-bearing capacity, low friction, and outstanding wear resistance, making them the ideal choice for various industrial applications.

Product Description:

Our product bearings are meticulously engineered to offer unrivaled performance within exacting environments. These bearings are characterized by a distinct composition, consisting of a high - quality brass alloy with embedded solid lubricants. This composition ensures seamless operation and significantly extends the service lifespan. The self - lubricating attributes obviate the necessity for external lubrication, thereby reducing maintenance expenditures and minimizing downtime.

The porous architecture of our product bearings enables the retention and release of lubricants in accordance with operational requirements. This ensures consistent performance, even under substantial loads and across varying speeds. This innovative design renders them especially appropriate for applications where conventional lubrication techniques are either impracticable or unfeasible.

Specifications:

| Parameter | Value |

|---|---|

| Material | Brass alloy with solid lubricants |

| Inner Diameter | 5mm - 300mm |

| Outer Diameter | 8mm - 350mm |

| Length | 5mm - 500mm |

| Load Capacity | Up to 140 MPa |

| Temperature Range | -40°C to +150°C |

| Friction Coefficient | 0.02 - 0.25 |

Why Choose Us?

- Over 20 years of industry experience

- State-of-the-art manufacturing facilities

- Rigorous quality control processes

- Customization capabilities to meet specific requirements

- Competitive pricing and flexible payment terms

- Expert technical support and after-sales service

- Quick turnaround times and reliable delivery

- Commitment to continuous innovation and improvement

Material:

Our Brass Self Lubricating bearings are made from a carefully selected brass alloy, typically consisting of copper, zinc, and other elements to enhance performance. The material is impregnated with solid lubricants such as graphite or PTFE, creating a self-lubricating composite that ensures smooth operation and extended bearing life.

Product Advantages:

- Superior Self-Lubrication: The embedded solid lubricants in our brass bearings provide consistent lubrication throughout the bearing's lifespan, eliminating the need for regular maintenance and reducing operational costs.

- Excellent Load-Bearing Capacity: Our product bearings can withstand high loads while maintaining their performance, making them suitable for demanding industrial applications.

- Low Friction and Wear: The combination of brass alloy and solid lubricants results in exceptionally low friction coefficients, reducing wear and extending the service life of both the bearing and the mating surface.

- Corrosion Resistance: The brass composition offers good resistance to corrosion, making these bearings suitable for use in harsh environments and marine applications.

- Wide Temperature Range: Our bearings maintain their performance across a broad temperature spectrum, from -40°C to +150°C, ensuring reliability in various operating conditions.

- Dimensional Stability: The brass alloy used in our bearings exhibits excellent dimensional stability, maintaining its shape and size even under load and temperature variations.

- Cost-Effective Solution: By eliminating the need for external lubrication systems and reducing maintenance requirements, our product bearings offer a highly cost-effective solution for many industrial applications.

Application Areas:

- Automotive Sector: Components within suspension systems, steering elements, and pedal assemblies.

- Aerospace Industry: Landing gear components, flight control systems, and cargo - loading apparatuses.

- Marine Applications: Deck - mounted equipment, propeller shaft arrangements, and rudder bearing systems.

- Agricultural Machinery Field: Pivot points, hydraulic cylinder units, and harvesting machinery.

- Material Handling Industry: Conveyor systems, roller components, and lift - truck mechanisms.

- Construction Equipment Sector: Excavator arm components, bulldozer blade assemblies, and crane - related components.

- Renewable Energy Industry: Wind turbine pitch and yaw control systems, solar - panel tracking mechanisms.

- Food Processing Industry: Mixing equipment, conveyor systems, and packaging machinery.

- Textile Machinery Industry: Spinning and weaving equipment, tension - control systems.

- Robotics and Automation Field: Joint mechanisms, linear - guide components, and end - of - arm tooling systems.

Quality Control:

We implement rigorous quality control measures throughout our production process.

Factory related:

Provide suitable bearing products and supporting services according to the needs of different customers

Packaging and Transportation:

We ensure secure packaging and reliable shipping for all orders.

Shipping Samples:

Sample orders are available for testing and evaluation.

Qualification Certification:

We hold ISO 9001 certification for quality management.

Production process related:

Select appropriate raw materials to produce bearing products that meet technical requirements

Exhibitions:

We regularly participate in international trade shows to showcase our products.

FAQ:

-

What is the typical lifespan of your Brass Self Lubricating bearings?

The lifespan varies depending on the application, but our bearings typically last 2-5 times longer than traditional bearings due to their self-lubricating properties.

-

Can your product bearings be customized for specific applications?

Yes, we offer customization services to meet unique requirements in terms of size, material composition, and performance characteristics.

-

Are your product bearings suitable for food-grade applications?

We offer food-grade versions of our bearings that comply with FDA regulations for use in food processing equipment.

-

How do I choose the right product bearing for my application?

Our technical team can assist you in selecting the most suitable bearing based on your specific operating conditions, load requirements, and environmental factors.

-

What is the minimum order quantity for your product bearings?

We offer flexible ordering options, including small quantity orders for specialized applications. Please contact us for details.

Contact Us:

For more information about our brass self lubricating bearings or to discuss your specific requirements, please contact us at info@wingold.cc. Our expert team is ready to assist you in finding the perfect bearing solution for your needs.

Learn about our latest products and discounts through SMS or email