- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

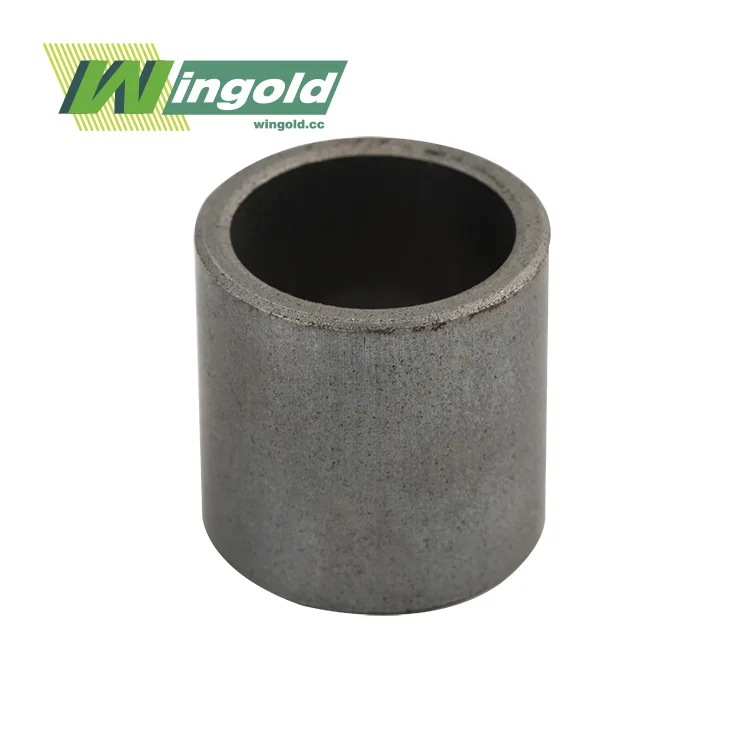

Bronze Bushings Custom

Bronze Bushings Custom: Tailored Solutions from Jiashan Wingold Bearing Co., Ltd.

Jiashan Wingold Bearing Co., Ltd. is your premier bronze bushings custom manufacturer and supplier. With our state-of-the-art facilities and expert engineering team, we offer unparalleled customization options, superior quality, and reliable performance. Our commitment to innovation and customer satisfaction sets us apart in the industry.

Product Description:

Our custom bronze bushings are the cornerstone of efficient machinery operation across various industries. Crafted with precision and care, these bushings offer exceptional wear resistance, low friction, and outstanding load-bearing capacity. We understand that every application is unique, which is why we specialize in tailoring our bronze bushings to meet your specific requirements.

Whether you need standard sizes or intricate custom designs, our team is equipped to deliver. We utilize advanced manufacturing techniques and high-quality bronze alloys to ensure each bushing meets the highest standards of performance and durability. Our custom bronze bushings are designed to withstand challenging environments, including high temperatures, corrosive conditions, and heavy loads.

Specifications:

| Feature | Details |

|---|---|

| Material | Bronze alloys (e.g., SAE 660, SAE 863, C90700) |

| Inner Diameter | 3mm - 500mm |

| Outer Diameter | 6mm - 600mm |

| Length | Up to 1000mm |

| Tolerance | As per customer requirements |

| Surface Finish | Ra 0.1 - 3.2 µm |

| Operating Temperature | -40°C to 350°C |

| Load Capacity | Up to 140 MPa |

Why Choose Us?

- Over 20 years of industry experience

- State-of-the-art manufacturing facilities

- In-house engineering and design team

- Rigorous quality control processes

- Competitive pricing and flexible MOQ

- On-time delivery and excellent customer support

- Customization capabilities to meet unique requirements

- Comprehensive material selection guidance

Material:

Our bronze bushings custom solutions utilize a range of high-performance bronze alloys, including but not limited to:

- SAE 660 (CuSn10Pb10): Excellent for general-purpose applications

- SAE 863 (CuAl10Fe5Ni5): Superior strength and corrosion resistance

- C90700 (CuSn10): High load capacity and wear resistance

Product Advantages:

- Tailored Solutions: Our custom bronze bushings are engineered to fit your exact specifications, ensuring optimal performance in your unique application. This perfect fit minimizes downtime and reduces maintenance costs.

- Superior Wear Resistance: The carefully selected bronze alloys offer exceptional wear properties, significantly extending the lifespan of your machinery components. This translates to fewer replacements and increased operational efficiency.

- Self-Lubricating Properties: Many of our bronze alloys feature inherent self-lubricating characteristics, reducing friction and wear even in challenging lubrication conditions. This self-lubricating quality ensures smooth operation and minimizes the need for frequent maintenance.

- Corrosion Resistance: Our custom bronze bushings exhibit excellent resistance to corrosion, making them ideal for use in harsh environments or applications exposed to chemicals or moisture. This durability ensures long-term reliability and reduces replacement frequency.

- Thermal Stability: Bronze's natural thermal conductivity allows for efficient heat dissipation, maintaining dimensional stability even under high-temperature conditions. This characteristic is crucial for applications where thermal expansion could lead to equipment failure.

Application Areas:

- Automotive: Engine components, suspension systems, steering mechanisms

- Aerospace: Landing gear bushings, wing flap actuators, hydraulic systems

- Marine: Propeller shaft bearings, rudder bushings, deck equipment

- Construction Equipment: Excavator arm bushings, loader pivot points, hydraulic cylinder bearings

- Agricultural Machinery: Tractor linkages, harvester bearings, irrigation systems

- Material Handling: Forklift mast bearings, conveyor systems, crane bushings

- Oil and Gas: Pump bushings, valve guides, offshore platform equipment

- Renewable Energy: Wind turbine pitch and yaw systems, solar panel tracking mechanisms

Quality Control:

We implement rigorous quality control measures throughout our production process.

Factory related:

Provide suitable bearing products and supporting services according to the needs of different customers

Packaging and Transportation:

We ensure secure packaging and reliable shipping for all orders.

Shipping Samples:

Sample orders are available for testing and evaluation.

Qualification Certification:

We hold ISO 9001 certification for quality management.

Production process related:

Select appropriate raw materials to produce bearing products that meet technical requirements

Exhibitions:

We regularly participate in international trade shows to showcase our products.

Quality Control:

We implement rigorous quality control measures throughout our production process.

Factory related:

Provide suitable bearing products and supporting services according to the needs of different customers

Packaging and Transportation:

We ensure secure packaging and reliable shipping for all orders.

Shipping Samples:

Sample orders are available for testing and evaluation.

Qualification Certification:

We hold ISO 9001 certification for quality management.

Production process related:

Select appropriate raw materials to produce bearing products that meet technical requirements

Exhibitions:

We regularly participate in international trade shows to showcase our products.

FAQ:

- What is the minimum order quantity for custom bronze bushings?

We offer flexible MOQs to accommodate your needs. Contact us for details. - How long does it take to produce custom bronze bushings?

Production time varies based on complexity and quantity. Typically, 2-4 weeks after design approval. - Can you provide technical support for installation?

Yes, our engineering team offers comprehensive technical support for all our products. - Do you offer prototyping services?

Absolutely. We can create prototypes to ensure perfect fit and function before full production. - What industries do you serve with your custom bronze bushings?

We serve a wide range of industries, including automotive, aerospace, marine, and more.

Contact Us:

Ready to explore Bronze Bushings Custom for your application? Contact our expert team at info@wingold.cc. Let's collaborate to enhance your machinery's performance and longevity with our tailored bronze bushings.

Learn about our latest products and discounts through SMS or email