- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

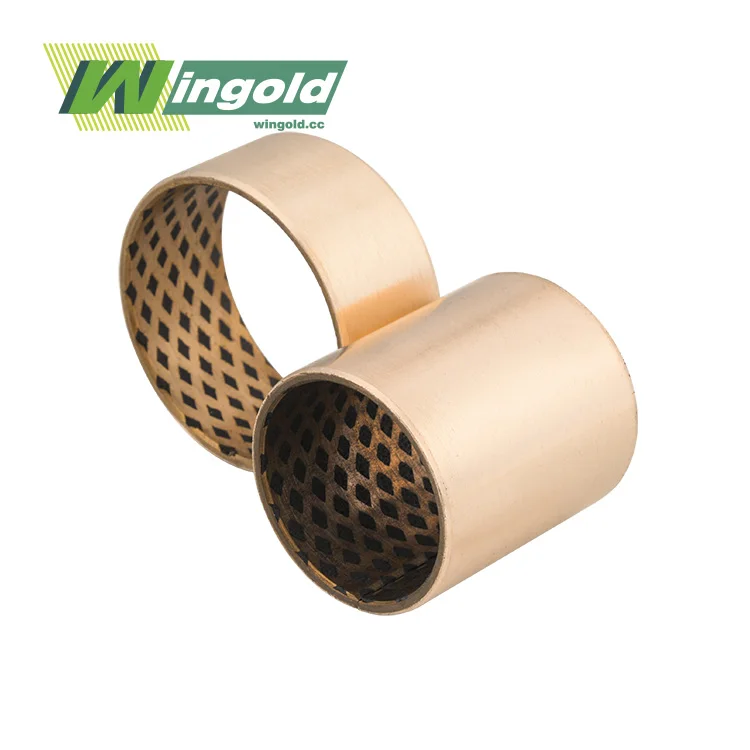

Oil Bronze Bearing

Oil Bronze Bearing: High-Performance Solutions by Jiashan Wingold Bearing Co., Ltd.

Jiashan Wingold Bearing Co., Ltd. is a leading manufacturer and supplier of oil bronze bearings, offering superior quality and innovative solutions. Our expertise in sliding bearing technology, combined with our commitment to excellence, positions us as a preferred choice for businesses seeking reliable and efficient bearing solutions.

Oil Bronze Bearing Introduction

Our oil bronze bearings are engineered to deliver exceptional performance in a wide range of applications. These self-lubricating bearings are made from high-quality bronze alloys infused with oil, providing outstanding wear resistance and low friction properties. The porous structure of the bronze material allows for continuous lubrication, ensuring smooth operation and extended service life.

Specifications:

| Feature | Description |

|---|---|

| Material | Oil-impregnated bronze alloy |

| Inner Diameter | 5mm - 300mm |

| Outer Diameter | 8mm - 350mm |

| Length | 5mm - 500mm |

| Operating Temperature | -40°C to 150°C |

| Load Capacity | Up to 140 N/mm² |

| Friction Coefficient | 0.03 - 0.08 |

Why Choose Us?

- Over 20 years of industry experience

- Custom solutions tailored to your needs

- Rigorous quality control processes

- Competitive pricing and flexible order quantities

- Fast turnaround times and reliable delivery

- Comprehensive technical support and after-sales service

Material:

Our oil bronze bearings are manufactured using a carefully selected bronze alloy, typically composed of copper, tin, and other elements. This composition is optimized for strength, durability, and self-lubrication properties. The porous structure of the material is impregnated with high-quality lubricating oil, ensuring consistent performance throughout the bearing's lifespan.

Product Advantages:

- Self-Lubrication: The oil-impregnated structure eliminates the need for external lubrication, reducing maintenance requirements and extending operational life.

- Low Friction: Our bearings offer exceptionally low friction coefficients, minimizing wear and energy consumption in your applications.

- High Load Capacity: Despite their compact size, these bearings can withstand significant loads, making them suitable for demanding industrial environments.

- Temperature Resistance: Engineered to perform reliably across a wide temperature range, from -40°C to 150°C.

- Corrosion Resistance: The bronze alloy provides excellent resistance to corrosion, enhancing durability in various operating conditions.

- Dimensional Stability: Our bearings maintain their shape and size under load, ensuring consistent performance and precision in your machinery.

- Quiet Operation: The self-lubricating properties contribute to smoother, quieter operation, reducing noise levels in your equipment.

Application Areas:

- Automotive Industry: Used in steering systems, suspension components, and transmission assemblies.

- Aerospace: Critical applications in landing gear, flap tracks, and actuator systems.

- Industrial Machinery: Widely used in conveyor systems, printing presses, and packaging equipment.

- Agricultural Equipment: Found in tractor linkages, harvester bearings, and irrigation systems.

- Marine Applications: Used in rudder bearings, propeller shafts, and deck equipment.

- Construction Equipment: Applied in excavator boom pivots, loader arms, and hydraulic cylinder bearings.

- Material Handling: Essential in forklift mast bearings, pallet truck wheels, and crane slew rings.

- Renewable Energy: Used in wind turbine pitch and yaw systems, as well as solar panel tracking mechanisms.

Quality Control:

We implement rigorous quality control measures throughout our production process.

Factory related:

Provide suitable bearing products and supporting services according to the needs of different customers

Packaging and Transportation:

We ensure secure packaging and reliable shipping for all orders.

Shipping Samples:

Sample orders are available for testing and evaluation.

Qualification Certification:

We hold ISO 9001 certification for quality management.

Production process related:

Select appropriate raw materials to produce bearing products that meet technical requirements

Exhibitions:

We regularly participate in international trade shows to showcase our products.

FAQ:

Q: What is the typical lead time for the products?

A: Our standard lead time is 2-3 weeks, depending on the order quantity and specifications.

Q: Can you provide custom sizes or designs?

A: Yes, we offer custom solutions tailored to your specific requirements. Contact our engineering team for details.

Q: What is the minimum order quantity?

A: We have flexible MOQ options. Please inquire for specific details based on your needs.

Q: How long do products typically last?

A: The lifespan varies depending on the application, but our bearings are designed for long-term performance, often lasting several years under normal operating conditions.

Q: Are your products interchangeable with other brands?

A: In many cases, yes. We can provide cross-reference information to help you find the right replacement.

Contact Us:

For more information about our oil bronze bearings or to discuss your specific needs, please contact us at info@wingold.cc. Our team of experts is ready to assist you in finding the perfect bearing solution for your application.

Learn about our latest products and discounts through SMS or email