932 bronze bushings are an important part of industrial power transfer systems that have a big effect on how well and how reliably the equipment works as a whole. These special bushings are made from high-quality SAE 932 bronze metal and have great wear protection and self-lubricating qualities that are important for heavy-duty uses. If you choose the right bronze bushings, you can cut down on upkeep costs by a huge amount, make equipment last longer, and cut down on costly downtime in a wide range of industry sectors, such as construction, power generation, and manufacturing.

Comprehending 932 Bronze Bushings — Specifications, Materials, and Benefits

The SAE 932 bronze metal is made up of carefully designed copper, tin, and lead that work together to give the best performance in tough industrial settings. This particular metal recipe strikes the perfect balance between being strong, not wearing down easily, and naturally lubricating, which makes it better than bronze materials.

Material Composition and Technical Specifications

Our 932 bronze bushings have a base made of a high-density copper metal. They also have diamond or hemispherical oil indentations that help keep the oil in place and spread it around better. Inner diameters range from 10mm to 200mm, outer diameters from 12mm to 220mm, and lengths from 10mm to 300mm are listed in the technical specs. When the temperature is between -40°C and 350°C, these joints work well and can handle loads of up to 140 MPa. The surface finish quality is between 0.8 and 3.2 μm, which makes sure that the machine runs smoothly and there is little friction. Tolerances can be changed to fit the needs of each customer, which makes it possible for precise fitting in many machinery uses.

Available Product Configurations

The versatility of these bronze bearings extends across multiple configurations to meet diverse industrial needs:

- Bearing shells that provide comprehensive support for rotating shafts in heavy machinery applications

- Flange bushings designed for applications requiring both radial and axial load support

- Thrust washers that handle axial loads in gear systems and transmission equipment

- Cup bushings offering complete enclosure for specialized mounting requirements

Each configuration maintains the superior material properties while addressing specific mechanical requirements in power transmission systems.

Comparing 932 Bronze Bushings with Alternative Materials for Industrial Use

Understanding how bronze bushings compare against alternative materials helps procurement professionals make informed decisions based on application requirements and total cost of ownership considerations.

Performance Advantages Over Steel and Plastic Alternatives

Compared to steel bearings, our bronze options are more resistant to rust and have natural greasing qualities that make them less likely to need to be serviced. Bronze bushings stay the same size even in the harshest working conditions, while plastic bushings can break down when exposed to high temperatures and loads. Bronze's naturally self-lubricating properties make it much less likely to stick than steel options. It can also hold more weight than most plastics. This mixture gives the equipment a longer useful life and lowers its running costs over its entire lifetime.

Cost-Effectiveness and Operational Benefits

While the initial investment in quality bronze bushings may exceed cheaper alternatives, the long-term operational benefits justify the cost difference. Reduced maintenance intervals, decreased lubrication requirements, and extended component life contribute to lower total cost of ownership. The excellent thermal conductivity of bronze also helps maintain optimal operating temperatures, preventing premature failure in high-stress applications.

Installation and Maintenance of 932 Bronze Bushings for Optimal Performance

For industrial power transfer systems to work well and last as long as possible, bronze bushing parts must be installed and maintained correctly.

Installation Best Practices

For an installation to go smoothly, the fixing areas must be properly prepared and the sizes must match. To make sure the load is spread out evenly, the fitting process needs to pay close attention to press-fit limits and alignment. Using the right fitting tools keeps the oil retention features in good shape and stops damage to the bushing surface. Temperature issues during fitting can change how well the parts fit together in the end, especially in situations where temperatures change a lot. Using the right torque standards and tightening steps in the right order makes sure that the stress is spread evenly across the part.

Maintenance and Monitoring Procedures

As part of regular inspections, wear patterns should be looked at visually and changes in size should be measured. Bronze doesn't need to be maintained as often because it naturally lubricates itself, but checking the working conditions on a regular basis can help find problems before they break down the equipment. Keeping an eye on working temperatures, load conditions, and any strange noise or sound patterns can help you spot problems early on. Keeping good records of maintenance tasks supports future maintenance plans and helps find the best times to replace things.

Procurement Guide for 932 Bronze Bushings – Sourcing, Customization & Supplier Selection

To buy bronze bushings effectively, you need to know what the provider can do, if they have quality standards, and what customization options are available that meet your unique business needs.

Supplier Evaluation Criteria

To find trusted providers, you need to look at their approval standards, manufacturing skills, and quality control methods. ISO 9001:2015 certification makes sure that quality control systems are always the same, and industry-specific certifications show that a company knows how to make bearings. Key factors in choosing a provider are the lead time, the minimum order quantity, and the ability to make changes to the size. Being able to offer professional help, failure analysis, and on-site advice makes the connection with the provider much more valuable.

Customization and Ordering Considerations

Customizing the size makes it possible to get the best fit in unique situations where normal sizes might not work. Knowing how long it takes to make a special order helps with planning upkeep and keeping track of supplies. Volume prices and a range of shipping choices make it easy to handle both planned replacements and repairs that need to be done right away.

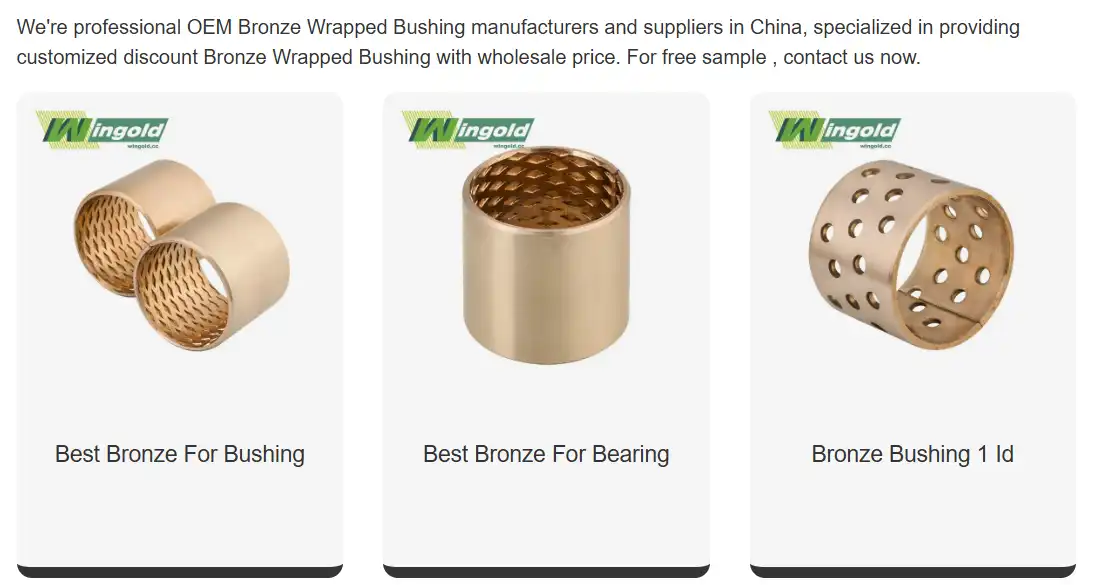

Wingold's Expertise in Bronze Bushing Manufacturing

Wingold has been making high-quality brass bushings for commercial use for more than 20 years and is known as a reliable company in the slide bearing business. Our modern factories have advanced CNC machine centers and centrifugal casting production lines that make sure we can control the sizes and qualities of the materials perfectly.

Manufacturing Capabilities and Quality Assurance

Our full-service testing labs do life acceleration tests and friction coefficient tests to make sure products work well before they are shipped, with a strong focus on bronze bushing lubrication. This very strict quality control method makes sure that every part meets foreign standards like ISO 4383 and ASTM B22. We are able to meet a wide range of customer needs thanks to our flexible production methods, which range from making prototypes quickly to producing 10,000 tons of goods every year. Our engineering team helps customers throughout the whole process by giving them one-on-one technology support. This helps them make their supply chains more efficient while also cutting costs.

Product Range and Application Support

Many different types of businesses use our wide range of products, such as those that make cars, boats, building equipment, farm machinery, aircraft parts, oil and gas activities, mining equipment, power generation systems, and food processing machinery. Because we've used a lot of different applications, we can make good suggestions for different use cases. Our self-lubricating bearings are better for the environment because they don't need any outside oils. This makes processes cleaner. This function is especially useful for businesses that want to be more eco-friendly while still running efficiently.

Conclusion

Choosing the right 932 bronze bushings has a big effect on how well industrial power transfer systems work, how reliable they are, and how much they cost to maintain. SAE 932 bronze metal has great benefits in terms of resistance to wear, load capacity, and operating life that make it worth the money to buy high-quality parts. Procurement pros can make choices that improve equipment performance by knowing the technical specs, the right way to put it, and how to keep it in good shape. Bronze bushing solutions can work well in tough industrial settings if you work with providers who have a lot of experience and offer full technical support as well as customization options.

FAQ

What distinguishes SAE 932 bronze from standard bronze alloys?

SAE 932 bronze contains a specific combination of copper, tin, and lead that provides superior wear resistance, self-lubricating properties, and load-bearing capacity compared to standard bronze alloys. The precise alloy composition ensures optimal performance in demanding industrial applications where reliability is critical.

Can these bushings operate effectively in high-temperature environments?

Yes, our bronze bushings are designed to operate effectively across temperature ranges from -40°C to 350°C. The thermal conductivity of bronze helps dissipate heat efficiently, maintaining optimal operating temperatures and extending component life even in challenging thermal conditions.

What customization options are available for specialized applications?

We offer comprehensive customization including non-standard sizes, custom surface finishes, specific tolerance requirements, and specialized configurations. Our engineering team works closely with customers to develop tailored solutions that meet unique application requirements while maintaining optimal performance characteristics.

Partner with Wingold for Superior Bronze Bushing Solutions

Ready to optimize your industrial power transmission systems with high-quality bronze bushings? Wingold combines decades of manufacturing expertise with advanced production capabilities to deliver reliable bushing solutions tailored to your specific requirements. Our ISO 9001:2015 certified facilities and comprehensive technical support ensure that you receive products that meet the highest quality standards.

Whether you need standard configurations or custom-designed solutions, our experienced team is ready to assist with your bronze bushing procurement needs. Contact us at info@wingold.cc to discuss your requirements with our technical specialists and discover why leading manufacturers choose Wingold as their trusted bronze bushing supplier.

References

1. American Society for Testing and Materials. "Standard Specification for Bronze Castings for Bearings and Bushings." ASTM B22-17, 2017.

2. International Organization for Standardization. "Plain bearings - Metallic multilayer plain bearings." ISO 4383:1991, 1991.

3. Society of Automotive Engineers. "Chemical Compositions of SAE Bronze Alloys." SAE J461, 2018.

4. American Society of Mechanical Engineers. "Bearing Design Guidelines for Industrial Power Transmission." ASME Power Transmission and Gearing Committee, 2020.

5. Industrial Bearings Institute. "Best Practices for Bronze Bushing Selection and Application in Heavy Machinery." Technical Publication IBI-2019-03, 2019.

6. National Institute of Standards and Technology. "Tribological Properties of Bronze Alloys in Industrial Applications." NIST Special Publication 800-145, 2021.