- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

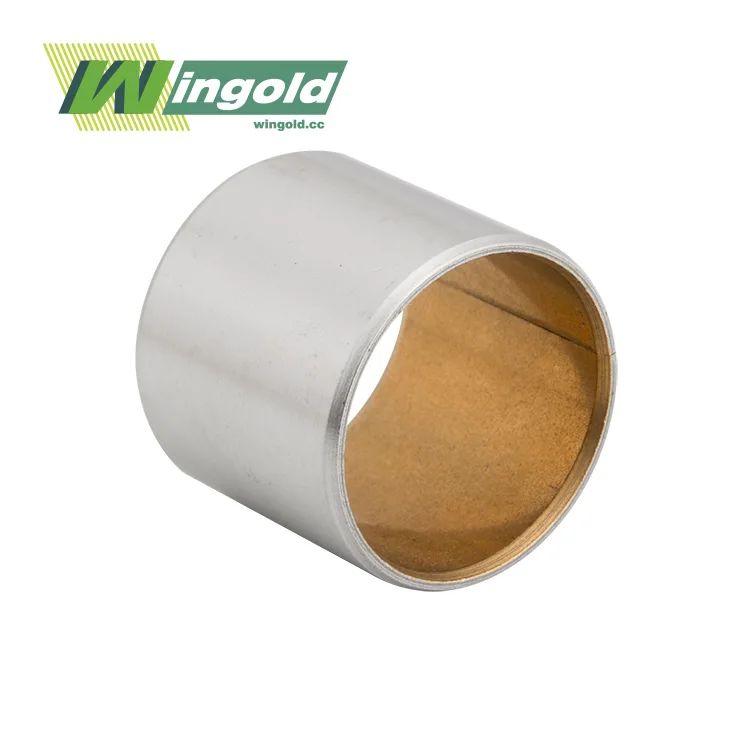

Aluminum Bronze Bearings

Jiashan Wingold Bearing Co., Ltd.: Your Trusted Aluminum Bronze Bearings Manufacturer

As a leading manufacturer and supplier of aluminum bronze bearings, Jiashan Wingold Bearing Co., Ltd. offers superior quality, customization options, and expert technical support. Our advanced manufacturing processes and commitment to innovation ensure that our bearings meet the highest industry standards, providing reliable performance and long-lasting durability for various applications.

Product Description:

Our high - end products are meticulously engineered to perform outstandingly in challenging environments. They exhibit remarkable wear resistance, low frictional properties, and substantial load - bearing capabilities. These self - lubricating bearings are highly suitable for applications where superior performance under heavy loads and in corrosive conditions is demanded. Due to their distinctive composition, our products offer excellent thermal conductivity and dimensional stability, guaranteeing consistent operation over a broad temperature range.

Specifications:

| Property | Value |

|---|---|

| Material | Aluminum Bronze (C95400, C95500, C95900) |

| Size Range | 10mm - 1000mm (ID) |

| Operating Temperature | -40°C to 350°C |

| Load Capacity | Up to 140 MPa |

| Coefficient of Friction | 0.1 - 0.2 |

| Hardness | 110 - 280 HB |

Why Choose Us?

- Over 20 years of industry experience

- ISO 9001:2015 certified manufacturing facilities

- Custom design and production capabilities

- Competitive pricing and flexible MOQ

- Rigorous quality control measures

- Global distribution network

- Responsive customer support

Material:

Our aluminum bronze bearings are crafted from high-quality alloys, including C95400, C95500, and C95900. These materials offer an optimal balance of strength, corrosion resistance, and wear properties, making them suitable for a wide range of industrial applications.

Product Advantages:

- Superior Corrosion Resistance: Our products excel in marine and chemical processing environments, resisting saltwater, acids, and other corrosive substances.

- High Load Capacity: Engineered to withstand heavy loads, these bearings maintain their performance under extreme pressure, reducing the risk of failure and extending equipment life.

- Self-Lubricating Properties: The unique composition of our products allows for self-lubrication, reducing maintenance requirements and improving overall system efficiency.

- Excellent Thermal Conductivity: These bearings efficiently dissipate heat, maintaining optimal operating temperatures and preventing premature wear.

- Dimensional Stability: Our products maintain their shape and size across a wide temperature range, ensuring consistent performance in varying conditions.

Application Areas:

- Marine Industry: Propeller shafts, rudder bearings, and stern tube bushings

- Oil and Gas: Pump bearings, valve seats, and offshore equipment

- Aerospace: Landing gear components and turbine engine bearings

- Heavy Machinery: Hydraulic cylinders, excavator bushings, and crane slew rings

- Power Generation: Hydroelectric turbine bearings and steam turbine components

- Mining and Construction: Crusher bearings, conveyor systems, and earth-moving equipment

- Food Processing: Mixer bearings, conveyor bushings, and packaging machinery

Quality Control:

We implement rigorous quality control measures throughout our production process.

Factory related:

Provide suitable bearing products and supporting services according to the needs of different customers

Packaging and Transportation:

We ensure secure packaging and reliable shipping for all orders.

Shipping Samples:

Sample orders are available for testing and evaluation.

Qualification Certification:

We hold ISO 9001 certification for quality management.

Production process related:

Select appropriate raw materials to produce bearing products that meet technical requirements

Exhibitions:

We regularly participate in international trade shows to showcase our products.

FAQ:

-

What is the minimum order quantity for the Aluminum Bronze Bearings?

Our minimum order quantity is flexible and depends on the specific product and customization requirements. Please contact our sales team for details.

-

Can you provide custom products for unique applications?

Yes, we specialize in custom solutions. Our engineering team will work closely with you to design and manufacture bearings that meet your specific needs.

-

What is the lead time for standard and custom orders?

Lead times vary depending on the product and order volume. Standard items typically ship within 2-4 weeks, while custom orders may take 4-8 weeks.

-

Do you offer technical support for product selection and installation?

Absolutely. Our experienced technical team is available to assist you with product selection, installation guidance, and troubleshooting.

-

Are your products compatible with specific industry standards?

Yes, our bearings are designed and manufactured to meet various industry standards, including ISO, ASTM, and DIN specifications.

Contact Us:

Ready to enhance your equipment's performance with our superior aluminum bronze bearings? Contact our expert team today at info@wingold.cc for personalized solutions and quotations.

Learn about our latest products and discounts through SMS or email