- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

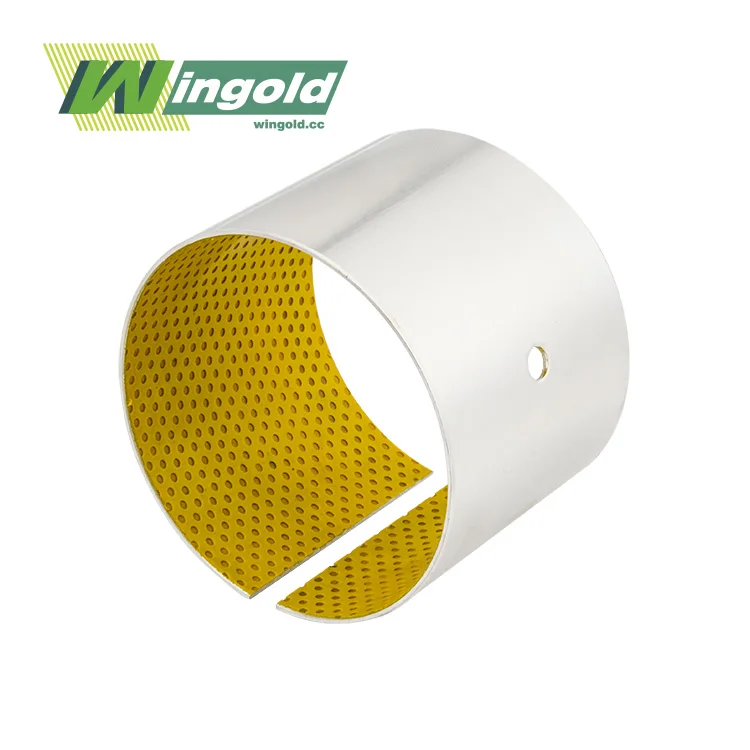

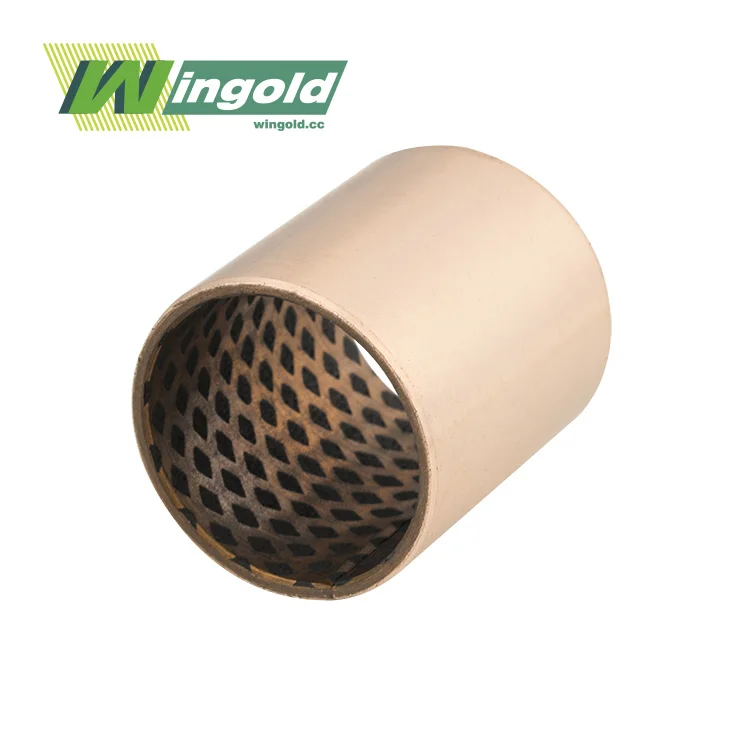

Hardened Bearing Sleeves

Jiashan Wingold Bearing Co., Ltd.: Your Trusted Hardened Bearing Sleeves Manufacturer & Supplier

As a leading manufacturer and supplier of hardened bearing sleeves WGB250, Jiashan Wingold Bearing Co., Ltd. takes pride in delivering superior quality, precision-engineered solutions for your sliding bearing needs. Our WGB250 sleeves offer unparalleled durability, exceptional performance, and cost-effectiveness, making us the go-to choice for discerning customers worldwide.

Hardened Bearing Sleeves Introduction

The hardened bearing sleeves WGB250 are meticulously designed and crafted to provide optimal performance in demanding applications. These sleeves feature a high-precision surface finish, exceptional wear resistance, and superior load-bearing capacity, ensuring extended service life and reduced maintenance costs. Our WGB250 sleeves are engineered to withstand extreme temperatures, high speeds, and heavy loads, making them ideal for various industrial applications.

Specifications:

| Parameter | Value |

|---|---|

| Material | High-grade alloy steel |

| Hardness | 58-62 HRC |

| Surface Finish | Ra 0.2-0.4 μm |

| Dimensional Tolerance | ±0.01 mm |

| Operating Temperature | -40°C to 200°C |

| Load Capacity | Up to 2000 kN |

| Inner Diameter Range | 50-500 mm |

| Outer Diameter Range | 60-550 mm |

Why Choose Us?

- Over 20 years of industry experience

- State-of-the-art manufacturing facilities

- Rigorous quality control processes

- Customization capabilities to meet specific requirements

- Competitive pricing and flexible terms

- Exceptional customer support and technical assistance

- Quick turnaround times and reliable delivery

Material:

Our hardened bearing sleeves WGB250 are manufactured using premium-grade alloy steel, carefully selected for its superior mechanical properties and heat treatment response. This ensures optimal hardness, wear resistance, and dimensional stability throughout the sleeve's service life.

Product Advantages:

- Enhanced Durability: The WGB250 sleeves undergo an advanced heat treatment process, resulting in a hardened surface that significantly extends the product's lifespan, even under extreme operating conditions.

- Precision Engineering: Our cutting-edge manufacturing techniques ensure tight dimensional tolerances and superior surface finish, promoting smooth operation and reducing friction.

- Excellent Load Capacity: The unique design and material composition of the WGB250 sleeves enable them to withstand high loads without deformation, ensuring reliable performance in demanding applications.

- Thermal Stability: These sleeves maintain their mechanical properties across a wide temperature range, making them suitable for use in various environments.

- Cost-Effective Solution: By offering extended service life and reduced maintenance requirements, our WGB250 sleeves help minimize downtime and overall operational costs for our customers.

Application Areas:

- Automotive Industry: Used in transmission systems, engine components, and suspension systems, providing reliable performance in high-stress environments.

- Aerospace: Employed in landing gear assemblies, flight control systems, and engine mounts, where precision and reliability are paramount.

- Heavy Machinery: Integrated into construction equipment, mining machinery, and agricultural implements, offering durability in harsh operating conditions.

- Steel Mills: Utilized in rolling mill equipment and material handling systems, withstanding high temperatures and heavy loads.

- Power Generation: Applied in turbines, generators, and pumps, ensuring efficient energy production and distribution.

- Marine Industry: Incorporated in propulsion systems, steering mechanisms, and deck machinery, resisting corrosion and providing long-term reliability.

- Oil and Gas: Used in drilling equipment, pumps, and valves, offering excellent performance in challenging environments.

- Paper and Pulp Industry: Integrated into various processing equipment, handling high-speed operations and corrosive conditions.

Quality Control:

We implement rigorous quality control measures throughout our production process.

Factory related:

Provide suitable bearing products and supporting services according to the needs of different customers

Packaging and Transportation:

We ensure secure packaging and reliable shipping for all orders.

Shipping Samples:

Sample orders are available for testing and evaluation.

Qualification Certification:

We hold ISO 9001 certification for quality management.

Production process related:

Select appropriate raw materials to produce bearing products that meet technical requirements

Exhibitions:

We regularly participate in international trade shows to showcase our products.

FAQ:

Q: What is the minimum order quantity for the products WGB250?

A: We typically accept minimum orders of 10 pieces, but we're flexible and can discuss your specific requirements.

Q: Can you provide custom sizes for the WGB250 sleeves?

A: Yes, we offer customization services to meet your exact specifications. Please contact our sales team for more information.

Q: What is the lead time for WGB250 sleeves?

A: Standard sizes usually ship within 2-3 weeks, while custom orders may take 4-6 weeks, depending on complexity and quantity.

Q: Do you offer any warranty on the WGB250 sleeves?

A: Yes, we provide a 12-month warranty against manufacturing defects under normal usage conditions.

Q: Can you provide technical support for installation and maintenance?

A: Absolutely! Our team of experts is always ready to assist you with any technical queries or support needs.

Contact Us:

For more information about our hardened bearing sleeves WGB250 or to discuss your specific requirements, please don't hesitate to reach out to us at info@wingold.cc. Our dedicated team is ready to provide you with expert advice and tailored solutions to meet your sliding bearing needs.

Learn about our latest products and discounts through SMS or email