- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

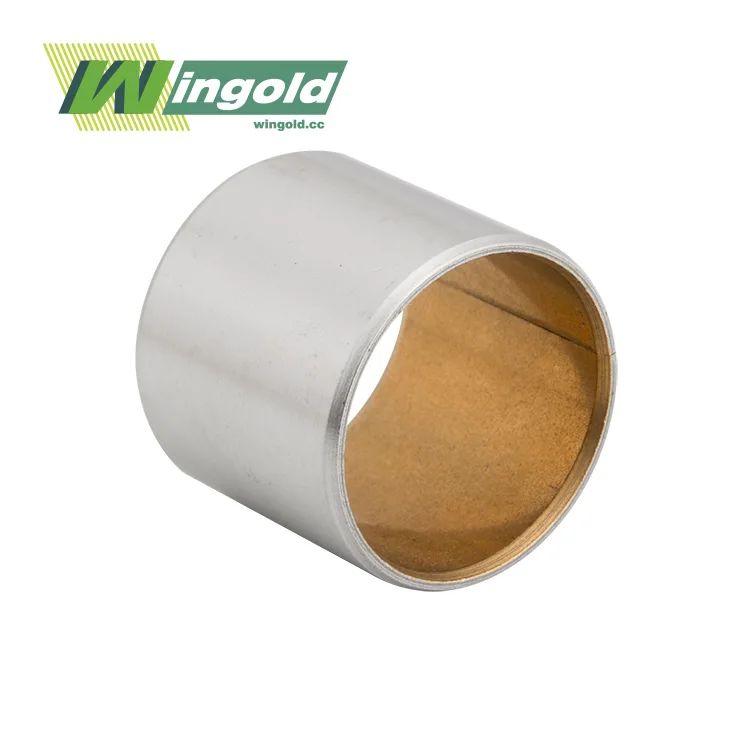

Aluminum Bronze Bearing

Aluminum Bronze Bearing: High-Performance Solutions by Jiashan Wingold

Jiashan Wingold Bearing Co., Ltd. is a leading manufacturer and supplier of premium aluminum bronze bearings. Our advanced manufacturing processes and superior materials ensure exceptional performance, durability, and reliability. With our extensive industry experience and commitment to innovation, we deliver tailored bearing solutions that meet the diverse needs of global B2B buyers across various sectors.

Product Description

Our products are engineered to excel in demanding applications, offering superior load-bearing capacity, excellent wear resistance, and outstanding corrosion resistance. These bearings are ideal for heavy-duty industrial machinery, marine equipment, and other challenging environments where traditional bearings may fall short.

Crafted from high-quality aluminum bronze alloys, our bearings provide a unique combination of strength and self-lubrication properties. This results in reduced maintenance requirements and extended service life, ultimately lowering your total cost of ownership.

Specifications

| Property | Value |

|---|---|

| Material | Aluminum Bronze Alloy |

| Load Capacity | Up to 140 MPa |

| Operating Temperature | -40°C to 350°C |

| Friction Coefficient | 0.08 - 0.12 |

| Corrosion Resistance | Excellent |

| Wear Resistance | Superior |

| Customization Options | Available |

Why Choose Us?

- Industry-leading expertise in product solutions

- Cutting-edge manufacturing facilities for consistent quality

- Flexible customization options to meet specific application needs

- Comprehensive technical support from pre-sales to after-sales

- Competitive pricing without compromising on quality

- Robust quality control measures ensuring product reliability

- Global shipping capabilities with on-time delivery

Material

Our aluminum bronze bearings are manufactured using premium-grade alloys, carefully selected for their exceptional mechanical properties and corrosion resistance. The composition typically includes copper, aluminum, iron, and other elements in precise ratios, optimized for specific application requirements.

Product Advantages

Jiashan Wingold's products offer numerous advantages that set them apart in the industry:

- Superior Load Capacity: Our bearings can withstand high loads without deformation, making them ideal for heavy-duty applications.

- Excellent Wear Resistance: The unique alloy composition results in exceptional wear resistance, significantly extending the bearing's service life.

- Outstanding Corrosion Resistance:The products exhibit remarkable resistance to corrosion, even in harsh marine environments.

- Self-Lubricating Properties: The material's inherent lubricity reduces friction and wear, minimizing the need for external lubrication.

- High-Temperature Performance: Our bearings maintain their mechanical properties at elevated temperatures, ensuring reliable operation in diverse conditions.

- Low Maintenance: The combination of wear resistance and self-lubrication translates to reduced maintenance requirements and lower operational costs.

- Customization Flexibility: We offer tailored solutions to meet specific application needs, ensuring optimal performance in your unique operating conditions.

Application Areas

Our Aluminum Bronze Bearing find extensive use across various industries:

- Marine and Offshore: Propeller shafts, rudder bearings, and winch systems

- Oil and Gas: Pumps, compressors, and drilling equipment

- Mining and Construction: Heavy machinery bearings and bushings

- Power Generation: Turbine bearings and generator components

- Aerospace: Landing gear components and actuator bearings

- Automotive: Suspension systems and steering mechanisms

- Food Processing: Bearings for high-temperature and corrosive environments

- Material Handling: Conveyor systems and lifting equipment

- Steel Mills: Rolling mill bearings and furnace components

- Paper and Pulp: Bearings for high-moisture environments

Quality Control:

We implement rigorous quality control measures throughout our production process.

Factory related:

Provide suitable bearing products and supporting services according to the needs of different customers

Packaging and Transportation:

We ensure secure packaging and reliable shipping for all orders.

Shipping Samples:

Sample orders are available for testing and evaluation.

Qualification Certification:

We hold ISO 9001 certification for quality management.

Production process related:

Select appropriate raw materials to produce bearing products that meet technical requirements

Exhibitions:

We regularly participate in international trade shows to showcase our products.

FAQ

Q: What makes products superior to traditional bearings?

A: The products offer excellent corrosion resistance, high load capacity, and self-lubricating properties, making them ideal for challenging environments where traditional bearings may fail.

Q: Can you provide custom product solutions?

A: Yes, we specialize in tailoring our products to meet specific application requirements. Our engineering team works closely with clients to develop optimal solutions.

Q: What is the typical lead time for the product orders?

A: Lead times vary depending on the complexity and quantity of the order. Generally, we aim for 2-4 weeks for standard products and 4-6 weeks for custom solutions.

Q: Do you offer technical support for the product integration?

A: Absolutely. Our team of experienced engineers provides comprehensive technical support from the design phase through implementation and maintenance.

Q: Are your products environmentally friendly?

A: Yes, our manufacturing processes adhere to strict environmental standards, and the long service life of our bearings contributes to reduced waste and resource consumption.

Contact Us

For more information about our aluminum bronze bearings or to discuss your specific needs, please contact us at info@wingold.cc. Our team of experts is ready to provide you with tailored solutions that enhance your equipment's performance and reliability.

Learn about our latest products and discounts through SMS or email