The Fundamentals of Small Bronze Bushings

Composition and Manufacturing

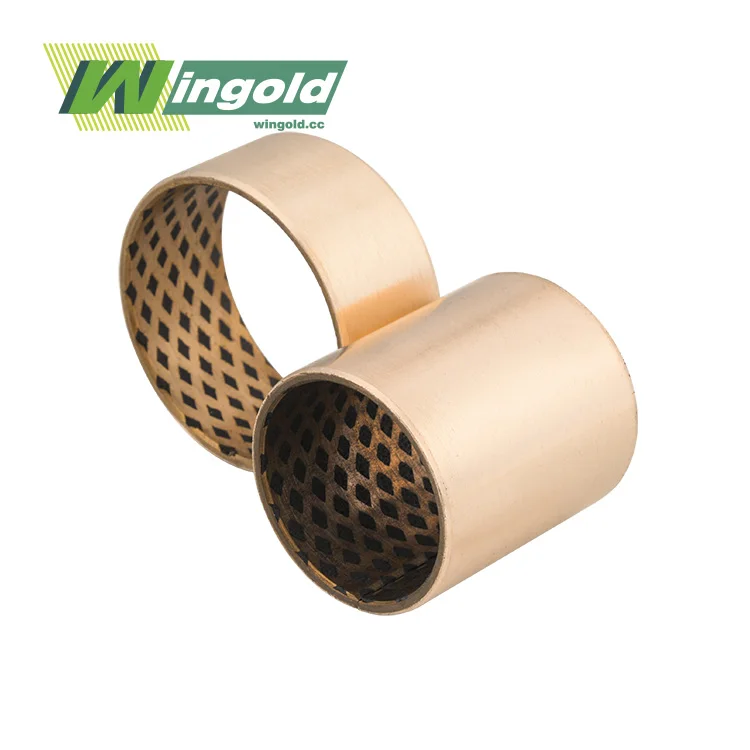

Small bronze bushings are typically manufactured from premium bronze alloys such as C86300 manganese bronze or C93200 bearing bronze. These alloys are specifically selected due to their outstanding mechanical characteristics, which include high compressive strength, superior resistance to wear, and excellent protection against corrosion in challenging environments. Such properties make them ideal for applications where components must withstand heavy loads, continuous friction, and exposure to moisture or chemicals. The combination of durability and reliability ensures small bronze bushings deliver long service life with minimal maintenance.

Small bronze bushings are typically manufactured from premium bronze alloys such as C86300 manganese bronze or C93200 bearing bronze. These alloys are specifically selected due to their outstanding mechanical characteristics, which include high compressive strength, superior resistance to wear, and excellent protection against corrosion in challenging environments. Such properties make them ideal for applications where components must withstand heavy loads, continuous friction, and exposure to moisture or chemicals. The combination of durability and reliability ensures small bronze bushings deliver long service life with minimal maintenance.

Key Characteristics

Small bronze bushings boast several key characteristics that make them ideal for a wide range of applications:

- High load capacity: Capable of withstanding loads up to 140 MPa

- Wide operating temperature range: Functional from -40°C to 150°C

- Low friction coefficient: Typically between 0.08 and 0.12

- Excellent wear resistance: Significantly extends equipment service life

- Self-lubricating properties: Porous structure allows for oil impregnation

- Superior thermal conductivity: Helps maintain optimal operating temperatures

Dimensional Specifications

Small bronze bushings are available in a variety of sizes to accommodate different applications:

- Inner Diameter: 3mm - 50mm

- Outer Diameter: 5mm - 60mm

- Length: 5mm - 100mm

These dimensions can be customized to meet specific requirements, ensuring a perfect fit for any application.

Applications and Industries

Versatility in Industrial Use

The versatility of small bronze bushings makes them invaluable across numerous industries. Their ability to withstand harsh conditions, coupled with their self-lubricating properties, makes them ideal for applications where regular maintenance is challenging or impossible.

Some key industries that rely heavily on small bronze bushings include:

- Automotive: Used in steering systems, suspension components, and engine parts

- Aerospace: Critical in landing gear assemblies and control surface mechanisms

- Marine: Essential for propeller shafts and rudder bearings

- Manufacturing: Utilized in various machine tools and production equipment

- Construction: Found in hydraulic systems of heavy machinery

Specific Applications

Within these industries, small bronze bushings find their way into numerous specific applications:

- Lifting and handling machinery: Providing smooth operation in cranes and hoists

- Plastic machinery: Ensuring precise movement in injection molding equipment

- Textile machinery: Facilitating smooth operation of spinning and weaving machines

- Food processing equipment: Offering corrosion resistance in washdown environments

- Hydraulic and pneumatic systems: Providing reliable sealing and low friction

Replacing Traditional Solutions

Small bronze bushings are increasingly replacing traditional cast copper sleeves in many applications. This shift is driven by the numerous advantages offered by bronze bushings, including:

- Reduced machinery size: Allowing for more compact and efficient designs

- Lower costs: Offering a more economical solution without compromising performance

- Improved wear resistance: Extending the service life of equipment

- Enhanced load-bearing capacity: Enabling machinery to handle heavier loads

Advantages and Considerations

Benefits of Small Bronze Bushings

The use of small bronze bushings offers numerous advantages:

- Extended equipment life: Superior wear resistance reduces the need for frequent replacements

- Reduced maintenance: Self-lubricating properties minimize the need for regular lubrication

- Improved efficiency: Low friction coefficient ensures smooth operation and reduces energy consumption

- Versatility: Suitable for a wide range of operating conditions and environments

- Cost-effectiveness: Long service life and reduced maintenance translate to lower overall costs

Environmental Considerations

Small bronze bushings also offer environmental benefits:

- Reduced lubricant use: Self-lubricating properties minimize the need for external lubricants

- Energy efficiency: Low friction operation reduces energy consumption in machinery

- Longevity: Extended service life means fewer replacements and less waste

Selection and Maintenance

When selecting small bronze bushings, consider the following factors:

- Load requirements: Ensure the bushing can handle the expected loads

- Operating conditions: Consider temperature, speed, and environmental factors

- Lubrication needs: Determine if self-lubricating properties are sufficient or if additional lubrication is required

- Dimensional requirements: Choose the correct size for your application

Proper maintenance of small bronze bushings typically involves:

- Regular inspection: Check for signs of wear or damage

- Cleaning: Remove any debris or contaminants that could affect performance

- Lubrication: If required, ensure proper lubrication according to manufacturer specifications

Conclusion

Small bronze bushings represent a pinnacle of engineering ingenuity, offering a perfect balance of performance, durability, and cost-effectiveness. Their widespread adoption across various industries is a testament to their versatility and reliability. As technology continues to advance, we can expect to see further innovations in the design and application of these essential components.

For those seeking high-quality small bronze bushings or customized solutions, Wingold Bearing stands ready to meet your needs. With our extensive experience, state-of-the-art manufacturing facilities, and commitment to excellence, we provide top-tier products that meet international standards. To learn more about our offerings or to discuss your specific requirements, please contact us at info@wingold.cc.

FAQ

What are the main advantages of small bronze bushings?

Small bronze bushings offer superior wear resistance, self-lubricating properties, high load capacity, excellent thermal conductivity, and corrosion resistance.

In which industries are small bronze bushings commonly used?

They are widely used in automotive, aerospace, marine, manufacturing, and construction industries, among others.

How do small bronze bushings contribute to environmental protection?

They reduce the need for external lubricants, improve energy efficiency, and have a long service life, reducing waste.

What factors should be considered when selecting small bronze bushings?

Key factors include load requirements, operating conditions, lubrication needs, and dimensional specifications.