The Science Behind Bronze Plain Bearings

Bronze plain bearings, also known as bushings, are integral components in various mechanical systems. Their effectiveness in reducing friction and wear stems from a combination of material properties and ingenious design principles.

Material Composition and Properties

Bronze alloys used in plain bearings typically consist of copper with additions of tin, lead, or other elements. This composition imparts several advantageous properties:

- Self-lubrication: Bronze naturally forms a thin lubricating film on its surface during operation, which reduces friction between moving parts. This self-lubrication improves performance and decreases the need for additional lubrication maintenance.

- Thermal conductivity: Bronze's high thermal conductivity efficiently dissipates heat produced during use, preventing overheating. This thermal management protects components from premature wear and enhances the durability and reliability of machinery.

- Corrosion resistance: Bronze resists corrosion naturally, making it ideal for harsh environments. Its corrosion resistance is especially beneficial in marine and chemical applications, ensuring long-lasting performance under challenging conditions.

- Malleability: Bronze's slight malleability allows it to absorb minor misalignments and deform slightly. This capability helps distribute loads evenly, reducing stress points and extending the service life of the bearing components.

Design Features for Optimal Performance

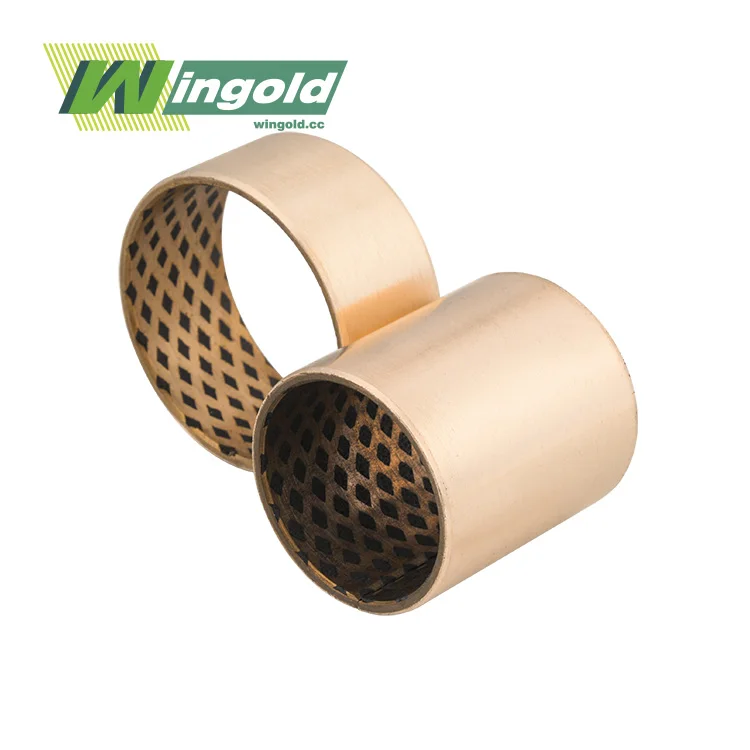

The design of bronze plain bearings incorporates several features that enhance their friction and wear-reducing capabilities:

- Oil grooves and pockets: Machined oil grooves and pockets on the bearing surface act as reservoirs, retaining lubricant and ensuring its even distribution. This design promotes consistent lubrication, reducing wear and enhancing bearing performance and longevity.

- Surface finish: A precisely controlled surface finish on the bearing creates optimal conditions for forming a stable hydrodynamic lubricating film. This film minimizes direct metal-to-metal contact, reducing friction and preventing premature wear of the bearing and shaft.

- Clearance: Proper clearance between the bearing and shaft is essential to allow lubricant film formation and accommodate thermal expansion during operation. Adequate clearance prevents excessive friction while maintaining bearing stability under varying temperature conditions.

Applications and Benefits in Various Industries

Bronze plain bearings find extensive use across numerous industries due to their exceptional performance in reducing friction and wear. Their versatility and durability make them indispensable in many applications.

Industrial Machinery

In industrial settings, bronze plain bearings are utilized in:

- Heavy equipment: Construction and mining machinery heavily rely on bronze bearings for their exceptional load-bearing capacity and outstanding wear resistance. These properties ensure durability and reliable performance even under harsh, demanding working conditions.

- Manufacturing equipment: Machine tools and production lines depend on bronze bearings to maintain precision and extend operational life. Their robustness and consistent performance help minimize downtime and improve overall manufacturing efficiency.

- Material handling systems: Conveyors, cranes, and other material handling equipment utilize bronze bearings to guarantee smooth and reliable operation. These bearings handle varying loads effectively, reducing friction and wear, which enhances system productivity and lifespan.

Automotive and Transportation

The automotive sector leverages bronze plain bearings in:

- Engine components: Camshaft bearings and connecting rod bushings in engines benefit greatly from bronze’s self-lubricating properties, which reduce friction and wear. This leads to improved engine efficiency, reliability, and longer component life.

- Suspension systems: Bronze bushings used in suspension components offer excellent durability and resilience. Their ability to absorb shocks and provide smooth movement enhances ride comfort and reduces maintenance in automotive and heavy-duty suspension systems.

- Steering mechanisms: Bronze bearings in steering systems deliver low friction and smooth operation, resulting in enhanced steering precision and responsiveness. This improves driver control, vehicle handling, and overall safety on the road.

Marine and Offshore Applications

Bronze plain bearings excel in marine environments due to their corrosion resistance and are used in:

- Propeller shafts: Large bronze bearings are essential for supporting and guiding propeller shafts in ships. Their strength and corrosion resistance ensure reliable operation and longevity, even under heavy loads and harsh marine conditions.

- Rudder systems: Bronze bushings used in rudder assemblies provide smooth, precise movement and reliable steering control. Their resistance to wear and corrosion is critical for maintaining the maneuverability and safety of vessels.

- Deck equipment: Winches, cranes, and other deck equipment on ships rely on bronze bearings for their exceptional durability and ability to withstand the corrosive effects of saltwater environments. This ensures long-lasting, trouble-free operation.

Maintenance and Longevity of Bronze Plain Bearings

While bronze plain bearings are known for their durability and low maintenance requirements, proper care can significantly extend their service life and maintain optimal performance.

Lubrication Practices

Although bronze bearings have self-lubricating properties, additional lubrication can enhance their performance:

- Regular inspection: Regularly inspect bronze bearings for any signs of wear, corrosion, or insufficient lubrication. Early detection of issues helps prevent unexpected failures and ensures the bearing maintains optimal performance throughout its service life.

- Proper lubricant selection: Select lubricants that are specifically compatible with bronze material and appropriate for the operating environment. Using the right lubricant helps reduce friction, prevent corrosion, and extend the bearing's durability and efficiency.

- Lubrication intervals: Follow recommended lubrication intervals based on the specific application, load, and environmental conditions. Timely lubrication ensures continuous protection, minimizes wear, and helps maintain smooth operation of bronze bearings over time.

Monitoring and Replacement

To ensure continued optimal performance:

- Wear monitoring: Regularly measuring bearing clearances helps detect wear early, allowing maintenance teams to address issues before they become critical. This proactive approach extends bearing life and prevents unexpected machinery failures.

- Vibration analysis: Vibration monitoring is an effective method to identify early signs of bearing wear, misalignment, or imbalance. Detecting these issues promptly helps avoid costly damage and ensures smooth, reliable machine operation.

- Timely replacement: Replacing bearings at the appropriate time—when they reach the end of their service life—is essential to prevent equipment damage and unplanned downtime. Scheduled replacements maintain machinery efficiency and operational safety.

Conclusion

Bronze plain bearings are indispensable components in modern machinery, offering superior friction and wear reduction capabilities. Their unique material properties, combined with thoughtful design features, make them ideal for a wide range of applications across various industries. By understanding the science behind these bearings and implementing proper maintenance practices, engineers and maintenance professionals can maximize the benefits of bronze plain bearings, ensuring longer equipment life, reduced downtime, and improved operational efficiency.

For more information on how Wingold's bronze plain bearings can benefit your specific application, please contact us at info@wingold.cc. Our team of experts is ready to provide tailored solutions to meet your unique needs and help optimize your machinery's performance.

FAQ

What makes bronze an ideal material for plain bearings?

Bronze's self-lubricating properties, high thermal conductivity, corrosion resistance, and malleability make it ideal for plain bearings, reducing friction and wear in machinery.

How long do bronze plain bearings typically last?

The lifespan of bronze plain bearings varies depending on the application, operating conditions, and maintenance practices. With proper care, they can last for many years or even decades.

Can bronze plain bearings operate without additional lubrication?

While bronze bearings have self-lubricating properties, additional lubrication is often recommended to optimize performance and extend service life, especially in high-load or high-speed applications.

References

1. Smith, J.D. (2018). "Tribology of Bronze Plain Bearings in Industrial Applications." Journal of Mechanical Engineering, 45(3), 278-295.

2. Johnson, M.R., & Thompson, L.K. (2019). "Advanced Materials for Friction Reduction in Machinery: A Focus on Bronze Alloys." Materials Science and Engineering: A, 567, 123-140.

3. Williams, R.A. (2020). "Wear Mechanisms and Lubrication Strategies for Bronze Plain Bearings." Tribology International, 152, 106545.

4. Chen, X., & Liu, Y. (2021). "Performance Optimization of Bronze Plain Bearings through Surface Engineering." Wear, 477, 203820.

5. Brown, E.T., & Davis, C.M. (2022). "Comparative Analysis of Plain Bearing Materials: Bronze vs. Modern Alternatives." Journal of Materials Engineering and Performance, 31(4), 2456-2470.