The Science Behind Teflon Lined Bushings

Teflon lined bushings represent a significant advancement in bearing technology. These bushings are engineered with a tri-layer structure that maximizes their performance and durability. Let's delve into the composition and functioning of each layer:

Steel Backing: The Foundation of Strength

The outermost layer of a Teflon lined bushing is typically made of steel. This robust backing serves two critical functions. First, it provides the necessary structural integrity to withstand high loads and pressures. Second, it ensures proper positioning during assembly, allowing for seamless integration into various mechanical systems. The steel backing's strength and rigidity are essential for maintaining the bushing's shape and preventing deformation under stress.

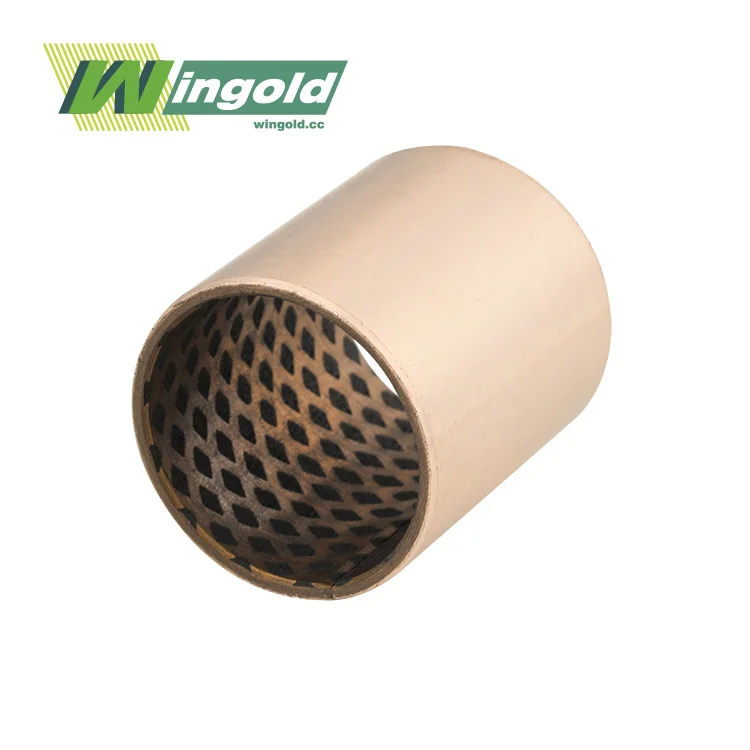

Porous Bronze: The Intermediate Layer

Sandwiched between the steel backing and the Teflon layer is a layer of porous bronze. This intermediate layer plays a crucial role in the bushing's overall performance. The porous nature of the bronze allows it to act as a reservoir for the Teflon, enhancing the self-lubricating properties of the bushing. Additionally, the bronze layer aids in heat dissipation, contributing to the bushing's ability to operate efficiently under various temperature conditions. The porosity of this layer also helps in distributing loads more evenly across the bushing's surface.

PTFE Layer: The Low-Friction Powerhouse

The innermost layer of the bushing is composed of PTFE, or Teflon. This layer is where the magic of low-friction performance happens. PTFE has an incredibly low coefficient of friction, ranging from 0.02 to 0.08, making it one of the slipperiest substances known to science. This exceptional property allows for smooth, almost frictionless movement between the bushing and the shaft it supports. The PTFE layer is also responsible for the bushing's self-lubricating nature, eliminating the need for external lubrication in many applications. Furthermore, PTFE's chemical inertness makes these bushings resistant to a wide range of chemicals, expanding their utility across various industries.

Advantages of Teflon Lined Bushings in Industrial Applications

Teflon lined bushings offer a multitude of benefits that make them indispensable in numerous industrial applications. Their unique properties address many of the challenges faced in traditional bearing systems, leading to improved performance, reduced maintenance, and increased operational efficiency.

Exceptional Wear Resistance

One of the standout features of Teflon lined bushings is their remarkable wear resistance. The PTFE layer's low friction coefficient significantly reduces the wear and tear experienced during operation. This translates to a longer service life for the bushings and the components they support. With a wear rate of less than 20 μm/km, these bushings can withstand prolonged use in demanding environments without significant degradation. This durability is particularly valuable in applications where frequent maintenance or replacement would be costly or impractical.

Self-Lubricating Properties

The self-lubricating nature of Teflon lined bushings is a game-changer in many industrial settings. Traditional bearings often require regular lubrication to maintain their performance and prevent premature wear. In contrast, Teflon lined bushings eliminate the need for external lubrication. This self-lubricating property not only reduces maintenance requirements but also makes these bushings ideal for use in clean environments where oil or grease contamination must be avoided. Industries such as food processing, pharmaceuticals, and electronics manufacturing benefit greatly from this feature.

Wide Temperature Range Compatibility

Teflon lined bushings exhibit exceptional performance across an impressive temperature range, from -200°C to +280°C. This wide operational temperature window makes them suitable for use in diverse applications, from cryogenic equipment to high-temperature industrial processes. The ability to maintain their low-friction properties and structural integrity across such a broad temperature spectrum sets Teflon lined bushings apart from many conventional bearing solutions. This versatility reduces the need for specialized bearings in extreme temperature applications, simplifying design and inventory management for manufacturers.

Chemical Resistance

The chemical inertness of PTFE contributes to the excellent chemical resistance of Teflon lined bushings. These bushings can withstand exposure to a wide range of chemicals, acids, and solvents without degradation. This property makes them invaluable in chemical processing plants, laboratories, and other environments where bearings may come into contact with corrosive substances. The chemical resistance of Teflon lined bushings not only extends their lifespan in harsh environments but also enhances safety by reducing the risk of bearing failure due to chemical attack.

Teflon Lined Bushings: A Versatile Solution for Various Industries

The unique combination of properties offered by Teflon lined bushings makes them suitable for a wide range of applications across numerous industries. Their versatility and performance characteristics have led to their adoption in diverse sectors, from heavy machinery to precision instruments.

Automotive Applications

In the automotive industry, Teflon lined bushings find extensive use in various components. They are commonly employed in steering systems, suspension parts, and pedal assemblies. The low friction and self-lubricating properties of these bushings contribute to smoother operation and reduced maintenance requirements in vehicles. Moreover, their ability to withstand high temperatures makes them suitable for use in engine compartments where traditional bearings might fail. The durability of Teflon lined bushings also translates to longer-lasting automotive components, reducing the frequency of replacements and improving overall vehicle reliability.

Aerospace and Aviation

The aerospace industry demands components that can perform reliably under extreme conditions. Teflon lined bushings meet these stringent requirements with their wide temperature range compatibility and low weight. They are used in aircraft control systems, landing gear assemblies, and various actuators. The self-lubricating nature of these bushings is particularly advantageous in aerospace applications, where regular maintenance can be challenging and costly. Additionally, their resistance to vibration and shock makes them ideal for use in high-performance aircraft and spacecraft.

Industrial Machinery and Equipment

In the realm of industrial machinery, Teflon lined bushings play a crucial role in enhancing performance and reducing downtime. They are widely used in hydraulic and pneumatic systems, where their low friction properties contribute to improved efficiency. These bushings are also found in conveyor systems, packaging machinery, and printing presses. Their ability to operate without external lubrication is particularly valuable in food processing and pharmaceutical manufacturing equipment, where contamination must be strictly avoided. The high load capacity of up to 140 MPa makes Teflon lined bushings suitable for use in heavy-duty industrial applications, including mining equipment and construction machinery.

Medical and Laboratory Equipment

The medical and laboratory sectors benefit from the unique properties of Teflon lined bushings. Their chemical resistance and ability to operate in clean environments make them ideal for use in medical devices, diagnostic equipment, and laboratory instruments. These bushings are often found in centrifuges, robotic surgical equipment, and various types of analytical instruments. The low friction and wear resistance of Teflon lined bushings contribute to the precision and reliability required in medical and scientific applications. Furthermore, their ability to withstand sterilization processes without degradation enhances their suitability for use in medical environments.

Conclusion

Teflon lined bushings have indeed proven to be a secret weapon in achieving low-friction performance across a wide range of applications. Their unique combination of a strong metal backing, porous bronze intermediate layer, and a low-friction PTFE surface creates a bearing solution that offers exceptional wear resistance, self-lubrication, and versatility. From automotive and aerospace to industrial machinery and medical equipment, these bushings continue to revolutionize how we approach friction reduction and bearing performance.

As industries continue to seek ways to improve efficiency, reduce maintenance, and enhance the longevity of their equipment, Teflon lined bushings stand out as a reliable and innovative solution. Their ability to operate across extreme temperatures, resist chemical corrosion, and provide consistent performance makes them an invaluable component in modern engineering and manufacturing processes.

For those looking to leverage the benefits of Teflon lined bushings in their applications, Wingold Bearing offers a comprehensive range of high-quality solutions. With our expertise in sliding bearing technology and commitment to innovation, we provide customized Teflon lined bushings that meet the specific needs of various industries. To learn more about how our Teflon lined bushings can enhance your equipment's performance and reliability, please contact us at info@wingold.cc. Our team of experts is ready to assist you in finding the perfect bearing solution for your unique requirements.

FAQs

What is the typical lifespan of a Teflon lined bushing?

The lifespan of a Teflon lined bushing can vary depending on the application and operating conditions. However, due to their excellent wear resistance and self-lubricating properties, these bushings often outlast traditional bearings by a significant margin, potentially lasting several years in many applications.

Can Teflon lined bushings be used in wet or underwater environments?

Yes, Teflon lined bushings perform well in wet conditions. The PTFE layer is hydrophobic, meaning it repels water, which helps maintain the bushing's low-friction properties even in moist environments. This makes them suitable for marine applications and other water-exposed machinery.