Understanding Brass Thrust Washers and Their Reusability

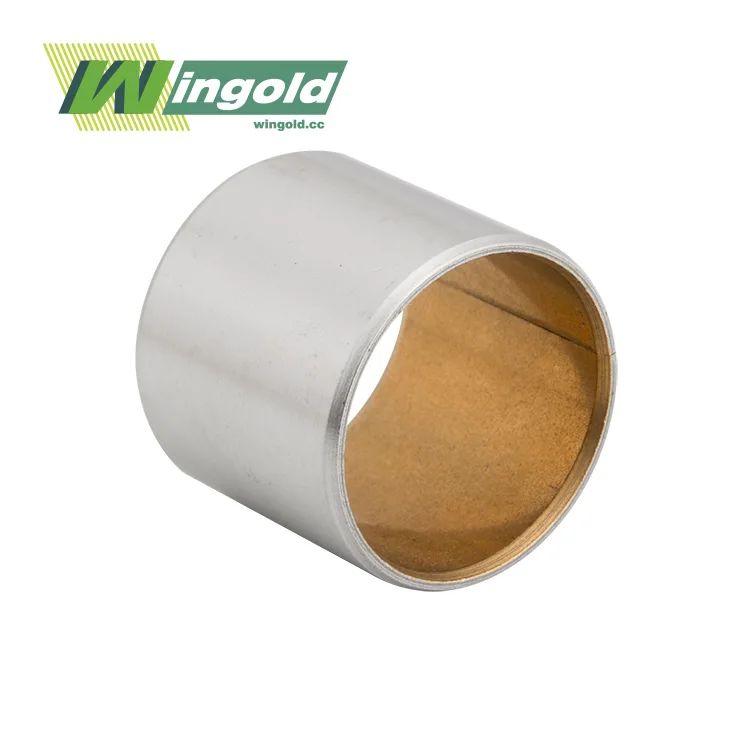

Composition and Properties of Brass Thrust Washers

Brass thrust washers are crafted from high-grade brass alloys, typically C26000 or C36000. These alloys offer a unique combination of properties that make them ideal for thrust bearing applications. The composition of brass, primarily copper and zinc, contributes to its excellent corrosion resistance, thermal conductivity, and low friction characteristics. These properties are fundamental to the washer's performance and longevity.

The inherent qualities of brass make these washers resilient to wear and tear. They can withstand high temperatures and maintain their structural integrity under significant loads. This resilience is a key factor in their potential for reuse. However, it's important to note that the specific alloy composition can affect the washer's durability and, consequently, its suitability for reuse.

Factors Affecting Reusability

Several factors influence whether a brass thrust washer can be reused:

- Wear and Tear: The extent of wear on the washer's surface is crucial. Excessive wear can compromise its ability to distribute loads evenly and maintain low friction.

- Deformation: Any bending or warping of the washer can affect its performance and potentially damage other components.

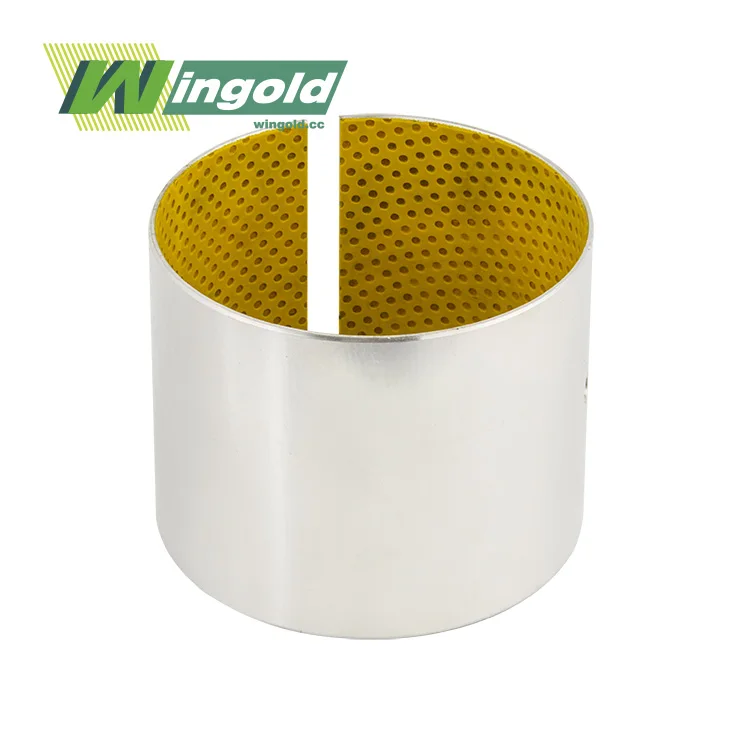

- Surface Finish: The smoothness of the washer's surface is vital for its friction-reducing properties. Scratches or pitting can increase friction and accelerate wear.

- Dimensional Changes: Repeated use under high loads can lead to slight changes in the washer's dimensions, potentially affecting its fit and function.

- Environmental Exposure: Exposure to corrosive substances or extreme conditions can degrade the washer's material properties.

These factors must be carefully evaluated before deciding to reuse a brass thrust washer. In some cases, even if the washer appears to be in good condition, the specific requirements of the application may necessitate the use of a new component to ensure optimal performance and safety.

Inspection and Assessment Procedures for Reusing Brass Thrust Washers

Visual Inspection Techniques

A thorough visual inspection is the first step in assessing a brass thrust washer for reuse. This process involves:

- Examining the surface for signs of wear, scratches, or pitting

- Checking for any discoloration that might indicate chemical reactions or overheating

- Looking for signs of deformation or bending

- Inspecting the edges for any chipping or damage

While visual inspection can reveal many issues, it's important to note that some forms of damage may not be visible to the naked eye. Therefore, visual inspection should be complemented by other assessment methods.

Measurement and Tolerance Checking

Precise measurement is crucial in determining whether a brass thrust washer remains within acceptable tolerances. This involves:

- Measuring the inner and outer diameters to ensure they match the original specifications

- Checking the thickness of the washer at multiple points to detect any uneven wear

- Verifying that the surface flatness is within the required range, typically between Ra 0.2 and 1.6

- Ensuring that dimensional tolerances remain within ±0.01mm to ±0.05mm, depending on the specific application requirements

Specialized measurement tools such as micrometers, calipers, and surface roughness testers may be necessary for accurate assessment. Any deviation from the original specifications could indicate that the washer is no longer suitable for reuse.

Non-Destructive Testing Methods

In some cases, particularly for critical applications, non-destructive testing methods may be employed to assess the internal structure and integrity of the brass thrust washer. These methods can include:

- Ultrasonic testing to detect internal flaws or cracks

- Eddy current testing to identify surface and near-surface defects

- X-ray inspection for detecting internal voids or inclusions

These advanced testing methods can provide valuable insights into the washer's condition that may not be apparent through visual inspection or measurement alone. However, they require specialized equipment and expertise to perform and interpret correctly.

Best Practices for Reusing Brass Thrust Washers

Cleaning and Preparation

If a brass thrust washer is deemed suitable for reuse after inspection and assessment, proper cleaning and preparation are essential. This process typically involves:

- Removing any debris or contaminants using appropriate solvents or cleaning agents

- Carefully cleaning the surface to restore its smoothness without causing additional damage

- Ensuring the washer is completely dry before reinstallation

- Applying a thin layer of appropriate lubricant if required by the application

It's crucial to use cleaning methods that won't compromise the washer's surface finish or material properties. Harsh abrasives or aggressive chemicals should be avoided to prevent unintentional damage.

Proper Installation Techniques

Correct installation is vital to ensure the reused brass thrust washer performs optimally. Key considerations include:

- Verifying that the mating surfaces are clean and free from damage

- Ensuring proper alignment during installation to prevent uneven loading

- Applying the correct amount of torque when tightening fasteners to avoid deformation

- Checking for proper clearance and fit after installation

Improper installation can lead to premature failure, even if the washer itself is in good condition. Following manufacturer guidelines and using appropriate tools are essential for successful reinstallation.

Monitoring and Maintenance

After reusing a brass thrust washer, ongoing monitoring and maintenance are crucial:

- Implementing a regular inspection schedule to check for signs of wear or degradation

- Monitoring operating temperatures and loads to ensure they remain within acceptable limits

- Keeping accurate records of the washer's usage history and performance

- Being prepared to replace the washer promptly if any issues are detected

Proactive monitoring can help identify potential problems early, preventing more serious failures and extending the useful life of the reused washer.

Conclusion

Reusing brass thrust washers can be a cost-effective and environmentally friendly practice when done correctly. However, it requires careful assessment, proper preparation, and ongoing vigilance to ensure continued performance and safety. The decision to reuse should always be based on a thorough evaluation of the washer's condition and the specific requirements of the application. When in doubt, consulting with experts or opting for new components may be the most prudent course of action. For more information on brass thrust washers and their applications, or to discuss your specific needs, please contact us at info@wingold.cc.

FAQ

How long can a brass thrust washer typically be reused?

The reusability of a brass thrust washer depends on various factors, including operating conditions and maintenance. With proper care, some washers can be reused multiple times, but there's no fixed lifespan.

Can I reuse a brass thrust washer in a different application?

It's generally not recommended to reuse a washer in a different application unless you can verify that it meets all the new application's requirements, including size, load capacity, and operating conditions.

How do I know if a brass thrust washer is beyond reuse?

Signs that a washer should not be reused include visible wear, deformation, significant thickness reduction, or if it falls outside the specified tolerances for the application.