Common Causes of 08dx08 Bushing Failures

Excessive Wear and Tear

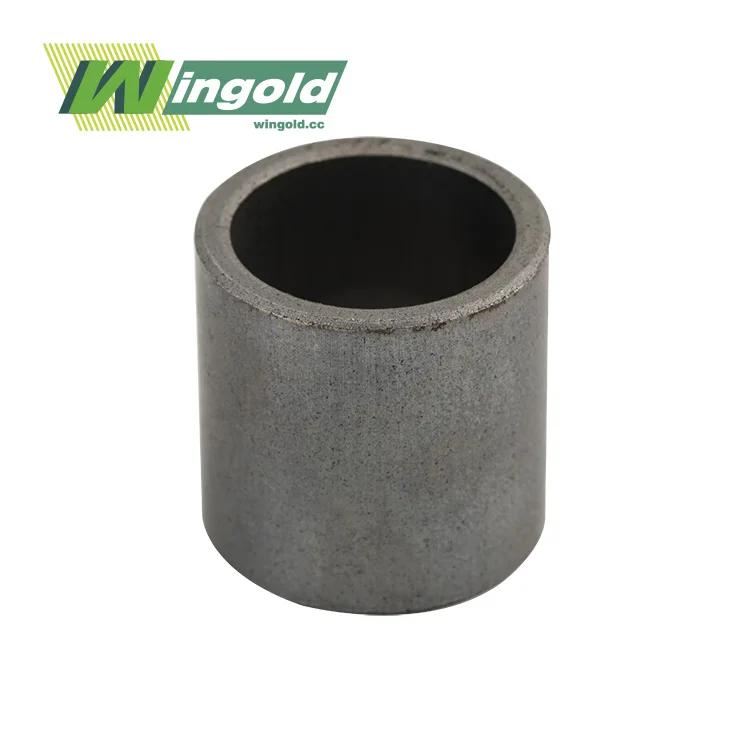

08dx08 bushings, despite their durability, are susceptible to wear over time. The self-lubricating properties of these bushings can diminish with prolonged use, leading to increased friction and accelerated deterioration. Factors such as high operational speeds, heavy loads, and harsh environmental conditions can exacerbate wear patterns.

To identify excessive wear, conduct regular visual inspections of the bushing surface. Look for signs of scoring, pitting, or uneven wear patterns. Utilize precision measuring tools to gauge the bushing's inner diameter and compare it to the original specifications. A deviation beyond acceptable tolerances indicates significant wear that may necessitate replacement.

Misalignment Issues

Proper alignment is paramount for optimal 08dx08 bushing performance. Misalignment can stem from various sources, including improper installation, shifting of machine components, or thermal expansion. When misaligned, bushings experience uneven stress distribution, leading to premature failure and potential damage to adjacent components.

To detect misalignment, employ dial indicators or laser alignment tools to measure shaft runout and bushing concentricity. Pay close attention to any unusual vibrations or noise during operation, as these can be telltale signs of misalignment issues. Address any discrepancies promptly to prevent cascading failures within the machinery.

Contamination and Corrosion

The ingress of contaminants or exposure to corrosive environments can significantly impact 08dx08 bushing performance. Particles such as dust, metal shavings, or abrasive materials can infiltrate the bushing, compromising its self-lubricating properties and accelerating wear. Corrosive agents may attack the bushing material, altering its structural integrity and surface characteristics.

Implement robust sealing solutions to mitigate contamination risks. Regularly inspect and clean the area surrounding the bushing, removing any visible debris. In corrosive environments, consider utilizing bushings with specialized coatings or materials engineered for enhanced chemical resistance. Proper lubrication practices, where applicable, can also help create a barrier against contaminants.

Troubleshooting Techniques for 08dx08 Bushing Failures

Diagnostic Procedures

When confronted with potential 08dx08 bushing failures, a systematic diagnostic approach is essential. Begin by thoroughly examining the bushing and surrounding components for visible signs of damage or wear. Employ specialized tools such as borescopes or endoscopes to inspect hard-to-reach areas without disassembly.

Measure critical parameters such as clearance, runout, and surface finish using precision instruments. Compare these measurements against manufacturer specifications to identify deviations. Utilize vibration analysis techniques to detect anomalies in the frequency spectrum that may indicate bushing-related issues.

Performance Testing

Conduct comprehensive performance tests to evaluate the 08dx08 bushing's functionality under various operating conditions. Monitor parameters such as temperature, friction coefficient, and load-bearing capacity. Employ thermal imaging cameras to identify hot spots or uneven heat distribution that may signal bushing distress.

Perform load testing to assess the bushing's ability to withstand specified forces without deformation or failure. Utilize specialized test rigs to simulate real-world operating conditions and measure bushing performance over extended periods. These tests can provide valuable insights into the bushing's current state and help predict potential future failures.

Root Cause Analysis

Identifying the underlying causes of 08dx08 bushing failures is crucial for implementing effective long-term solutions. Employ root cause analysis techniques such as the "5 Whys" method or fishbone diagrams to systematically trace failure pathways. Consider factors beyond the bushing itself, including system-wide influences that may contribute to premature wear or failure.

Analyze historical maintenance records and failure data to identify recurring patterns or trends. Collaborate with cross-functional teams, including design engineers and maintenance personnel, to gain diverse perspectives on potential failure mechanisms. This holistic approach enables the development of comprehensive solutions that address both immediate issues and underlying systemic problems.

Preventive Maintenance Strategies for 08dx08 Bushings

Lubrication Optimization

While 08dx08 bushings are designed to be self-lubricating, certain applications may benefit from supplementary lubrication to extend service life. Develop a tailored lubrication strategy based on operating conditions, environmental factors, and bushing material properties. Select lubricants compatible with the bushing material and appropriate for the specific application requirements.

Implement precision lubrication techniques, such as ultrasonic lubrication systems or micro-dosing applicators, to ensure optimal lubricant distribution. Establish a regular lubrication schedule and monitor lubricant condition to maintain optimal bushing performance. Consider implementing oil analysis programs to detect early signs of bushing wear or contamination.

Environmental Control

Controlling the operating environment is crucial for maximizing 08dx08 bushing longevity. Implement effective sealing solutions to prevent ingress of contaminants and moisture. In dusty or abrasive environments, consider installing filtration systems or air purifiers to minimize particle exposure.

Monitor and regulate temperature and humidity levels within the machinery to prevent thermal stress or condensation-related issues. In corrosive environments, implement protective measures such as vapor phase inhibitors or specialized coatings to safeguard the bushing and surrounding components.

Predictive Maintenance Techniques

Leverage advanced predictive maintenance technologies to monitor 08dx08 bushing health and anticipate potential failures. Implement continuous monitoring systems that utilize sensors to track key performance indicators such as vibration, temperature, and load. Employ machine learning algorithms to analyze this data and identify subtle changes that may indicate impending bushing issues.

Utilize condition-based maintenance approaches, scheduling interventions based on actual bushing condition rather than fixed time intervals. This approach optimizes maintenance resources and minimizes unnecessary downtime. Integrate predictive maintenance data into broader asset management systems to enable data-driven decision-making and long-term reliability improvements.

Conclusion

Effective troubleshooting and maintenance of 08dx08 bushings are essential for ensuring optimal machinery performance and longevity. By understanding common failure modes, implementing robust diagnostic procedures, and adopting proactive maintenance strategies, engineers and maintenance professionals can significantly extend bushing service life and minimize costly downtime. As bushing technology continues to evolve, staying informed about the latest advancements and best practices is crucial for maintaining a competitive edge in industrial operations. For further assistance or to explore customized bushing solutions tailored to your specific application needs, please contact our team of experts at info@wingold.cc.

FAQ

How often should 08dx08 bushings be inspected?

Inspection frequency depends on the application, but generally, quarterly visual inspections and annual detailed assessments are recommended.

Can 08dx08 bushings be refurbished?

In some cases, minor wear can be addressed through resurfacing, but replacement is often more cost-effective for severely worn bushings.

What are the signs of a failing 08dx08 bushing?

Common signs include increased noise, vibration, heat generation, and visible wear or scoring on the bushing surface.

How do I choose the right lubricant for my 08dx08 bushing?

Consider factors such as operating temperature, load, speed, and environmental conditions. Consult with a lubrication specialist for optimal selection.