Understanding the Advantages of Custom Bronze Bushings

Bronze bushings have been a staple in the engineering world for decades, and for good reason. Their unique properties make them an excellent choice for a wide range of applications, especially those involving intermittent motion. Let's delve into the key advantages that make custom bronze bushings an affordable and effective solution.

Superior Load-Bearing Capacity

One of the standout features of bronze bushings is their remarkable load-bearing capacity. Bronze alloys are known for their strength and durability, allowing them to withstand significant loads without deforming or failing. This makes them particularly suitable for applications where intermittent motion creates varying stress levels on the bearing surface.

Custom bronze bushings can be engineered with specific alloy compositions to further enhance their load-bearing capabilities. For instance, tin bronze alloys like SAE 863 (CuSn8) offer excellent strength and fatigue resistance, making them ideal for heavy-duty applications. The ability to customize the alloy composition allows engineers to fine-tune the bushing's performance to meet the exact requirements of their application.

Excellent Wear Resistance

Wear resistance is crucial in applications with intermittent motion, where frequent starts and stops can lead to accelerated wear. Bronze bushings excel in this area, offering superior wear resistance compared to many other materials. The inherent properties of bronze, combined with proper design and surface treatments, result in bushings that can maintain their performance over extended periods, even under challenging conditions.

Custom bronze bushings can be further enhanced with surface treatments or coatings to improve their wear resistance. For example, diamond-rolled surfaces or hemispherical oil holes can be incorporated into the design to improve lubrication and reduce friction, extending the bushing's service life.

Self-Lubricating Properties

Many bronze alloys used in custom bushings possess self-lubricating properties, which is a significant advantage in intermittent motion applications. These self-lubricating characteristics help reduce friction and wear, especially during start-up conditions when lubrication might be less than optimal.

The self-lubricating nature of bronze bushings can lead to reduced maintenance requirements and longer service intervals. This not only contributes to the overall affordability of the solution but also improves the reliability and uptime of the equipment in which they are installed.

Customization Options for Optimal Performance

The ability to customize bronze bushings is a key factor in their effectiveness as a solution for intermittent motion applications. Let's explore the various customization options available and how they contribute to optimal performance.

Dimensional Customization

Custom bronze bushings can be manufactured to precise dimensions, ensuring a perfect fit for your application. This level of customization allows for:

- Inner Diameters ranging from 3mm to 500mm

- Outer Diameters from 6mm to 600mm

- Lengths between 5mm and 1000mm

- Wall Thicknesses from 1.5mm to 50mm

The ability to specify exact dimensions ensures that the bushing integrates seamlessly into your design, optimizing performance and minimizing the need for additional modifications.

Alloy Selection

The choice of bronze alloy can significantly impact the bushing's performance. Different alloys offer varying levels of strength, wear resistance, and corrosion resistance. Some popular alloy options include:

- SAE 660 (CuSn10Pb10): Offers good wear resistance and low friction

- SAE 863 (CuSn8): Provides high strength and excellent corrosion resistance

- SAE 841 (CuSn10): Balances strength and wear resistance

- C93200 (High-lead bronze): Excellent for high-load, low-speed applications

- C90300 (Tin bronze): Offers high strength and good corrosion resistance

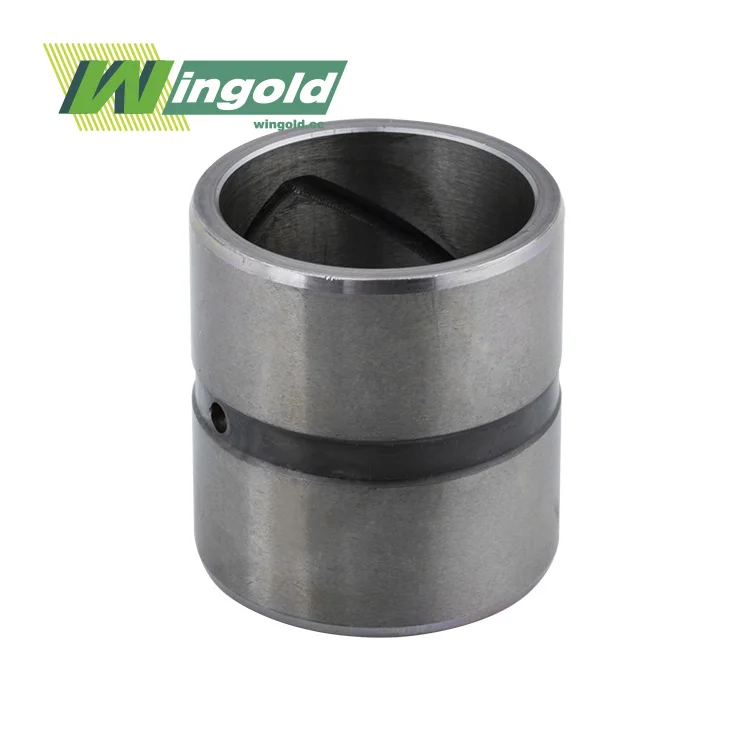

Surface Treatments and Patterns

Surface treatments and patterns can enhance the performance of custom bronze bushings, particularly in intermittent motion applications. Options include:

- Diamond-rolled surfaces for improved lubrication retention

- Hemispherical oil holes to facilitate lubricant distribution

- Custom groove patterns for specific lubrication requirements

- Coatings to enhance wear resistance or reduce friction

Applications and Industries Benefiting from Custom Bronze Bushings

Custom bronze bushings find applications across a wide range of industries, particularly where intermittent motion is a common occurrence. Let's explore some of the key industries and applications where these components prove invaluable.

Automotive and Transportation

In the automotive sector, custom bronze bushings are used extensively in various components that experience intermittent motion:

- Steering systems

- Suspension components

- Brake systems

- Door hinges and latches

The durability and wear resistance of bronze bushings make them ideal for these applications, where they must withstand frequent starts and stops, as well as varying loads.

Industrial Machinery and Manufacturing

Custom bronze bushings play a crucial role in many industrial machines and manufacturing equipment:

- Hydraulic and pneumatic systems

- Conveyor systems

- Robotic arms and automation equipment

- Packaging machinery

In these applications, the bushings' ability to handle high loads and intermittent motion while maintaining precise positioning is essential for efficient and reliable operation.

Construction and Mining Equipment

The rugged nature of construction and mining operations demands components that can withstand harsh conditions and heavy loads. Custom bronze bushings are used in:

- Excavator arms and buckets

- Bulldozer tracks and blades

- Crane pivot points

- Mining conveyor systems

The wear resistance and load-bearing capacity of bronze bushings make them well-suited for these demanding applications.

Marine and Offshore Industries

In marine environments, corrosion resistance is as important as wear resistance. Custom bronze bushings find applications in:

- Ship rudder systems

- Deck equipment

- Offshore platform machinery

- Underwater equipment

The corrosion resistance of certain bronze alloys, combined with their mechanical properties, makes them an excellent choice for these challenging environments.

Conclusion

Custom bronze bushings offer an affordable and effective solution for applications involving intermittent motion across various industries. Their superior load-bearing capacity, excellent wear resistance, and self-lubricating properties make them ideal for challenging environments and operating conditions. The ability to customize dimensions, alloy compositions, and surface treatments allows engineers to optimize these components for specific applications, ensuring optimal performance and longevity.

If you're looking for high-quality custom bronze bushings for your intermittent motion applications, look no further than Wingold Bearing. Our expertise in manufacturing precision components, combined with our commitment to customer satisfaction, ensures that you'll receive bushings tailored to your exact specifications. Contact us today at info@wingold.cc to discuss your custom bronze bushing needs and discover how we can help optimize your applications.

FAQs

What are the main advantages of using custom bronze bushings for intermittent motion applications?

Custom bronze bushings offer superior load-bearing capacity, excellent wear resistance, and self-lubricating properties. They can be tailored to specific dimensions and alloy compositions, making them ideal for various industries and applications involving intermittent motion.

How do custom bronze bushings compare to other bearing materials in terms of cost-effectiveness?

Custom bronze bushings often provide an excellent balance between performance and cost. While initial costs may be higher than some alternatives, their durability and low maintenance requirements often result in lower long-term costs.

Can custom bronze bushings be used in corrosive environments?

Yes, certain bronze alloys offer excellent corrosion resistance, making them suitable for use in marine and other corrosive environments. The specific alloy choice depends on the application requirements.