Understanding Metric Bronze Thrust Washers

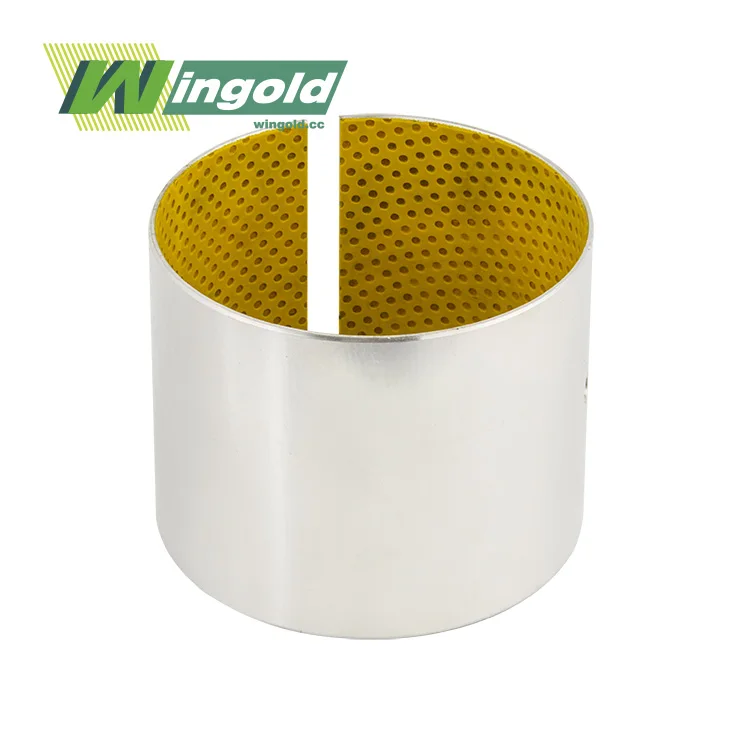

Composition and Properties

Metric bronze thrust washers are precision-engineered components crafted from high-quality bronze alloys. These alloys, most commonly CuSn8 or CuSn10, are selected for their exceptional balance of strength, durability, and naturally low-friction properties. The bronze material ensures outstanding resistance to wear, enabling the washers to perform reliably even under heavy loads or continuous use. Additionally, bronze’s superior thermal conductivity allows efficient heat dissipation, preventing excessive temperature buildup during operation. With their metric sizing, these washers meet international standards, making them highly adaptable across a wide variety of machinery applications.

Design Features

The design of metric bronze thrust washers incorporates several key features that enhance their performance. These washers often feature a smooth, polished surface on one side to minimize friction against moving parts. The opposite side may have oil grooves or a textured surface to improve lubrication retention. The thickness of these washers can range from 0.5mm to 10mm, with inner diameters spanning from 10mm to 200mm, accommodating various machinery requirements.

Applications

Metric bronze thrust washers are widely used across multiple sectors due to their strength and versatility. They are essential in hydraulic and pneumatic systems where reliable axial load management is critical, as well as in forging and pressing machine tools that demand consistent durability. In plastic machinery, lifting equipment, and port handling machines, they reduce wear and extend service life. Their use also extends to automotive engines, railway locomotives, and shipbuilding applications, where they provide stable support under axial loads, ensuring smooth performance of mechanical assemblies.

Installation Best Practices for Thrust Washers

Preparation and Inspection

Before installing metric bronze thrust washers, it is essential to conduct a thorough cleaning and inspection of both the washer itself and the mounting surfaces. Any signs of damage, surface warping, or contamination must be addressed before installation, as these imperfections can directly compromise performance. The mating surfaces should be carefully checked to ensure they are smooth, flat, and completely free from burrs, scratches, or irregularities. Even small defects can result in uneven loading, misalignment, or premature wear, reducing the service life and efficiency of the washer.

Proper Orientation

Correct orientation plays a critical role in the proper functioning of metric bronze thrust washers. During installation, the smooth and polished surface of the washer should always face the moving component to reduce friction and allow for even load distribution. If the washer has oil grooves or a textured surface on one side, this side should face the stationary component. This arrangement promotes improved lubrication retention and effective heat dissipation, ensuring optimal operating conditions and prolonging the washer’s service life.

Alignment and Fitment

Accurate alignment is another key factor when installing bronze thrust washers. The washer should be precisely centered and kept parallel to the mating surfaces to avoid uneven loading or mechanical stress. Adhering to the specified clearances of the application is crucial, as excessive or insufficient clearance can lead to reduced efficiency or even premature failure. In certain cases, stacking multiple washers to achieve the required thickness may be permissible, but such modifications should only be done if explicitly approved in the system’s design specifications.

Maintenance and Longevity of Metric Bronze Thrust Washers

Lubrication Considerations

Although bronze thrust washers inherently offer excellent low-friction characteristics, lubrication plays an important role in maximizing performance and service life. The type of lubricant used depends on application requirements, load conditions, and operating environment. For demanding systems, self-lubricating bronze alloys that incorporate solid lubricants such as graphite or PTFE within the material may be selected. These specialized alloys significantly reduce the dependence on external lubrication, making them ideal for machinery operating under limited maintenance schedules or in hard-to-reach environments.

Wear Monitoring

Regular inspection of metric bronze thrust washers is crucial for maintaining optimal performance. Look for signs of excessive wear, such as uneven thickness, scoring, or discoloration. Measure the washer thickness periodically and compare it to the original specifications to determine the wear rate. Establishing a predictive maintenance schedule based on these inspections can help prevent unexpected failures and extend machinery uptime.

Environmental Factors

The operating environment can significantly impact the performance and longevity of metric bronze thrust washers. These components can typically withstand temperatures ranging from -40°C to 150°C, but extreme temperatures may affect their properties. Consider factors such as corrosive atmospheres, abrasive particles, and moisture exposure when selecting and maintaining thrust washers. In challenging environments, additional protective measures or more frequent inspections may be necessary.

Conclusion

Understanding the proper installation and maintenance of metric bronze thrust washers is crucial for maximizing their performance and longevity in various mechanical applications. By following best practices for orientation, alignment, and ongoing care, engineers and maintenance professionals can ensure these critical components continue to manage axial loads effectively, reducing wear and extending machinery life. For more information on our range of metric bronze thrust washers and how they can benefit your specific application, please contact us at info@wingold.cc. Our team of experts is ready to provide tailored solutions to meet your unique requirements.

FAQ

Can metric bronze thrust washers be reused?

While it's possible to reuse thrust washers in some cases, it's generally recommended to replace them during maintenance to ensure optimal performance.

How often should thrust washers be inspected?

Inspection frequency depends on the application and operating conditions. Generally, inspections should be part of regular maintenance schedules, typically every 3-6 months.

Are metric bronze thrust washers suitable for high-temperature applications?

Yes, bronze thrust washers can typically operate in temperatures up to 150°C, making them suitable for many high-temperature applications.