- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

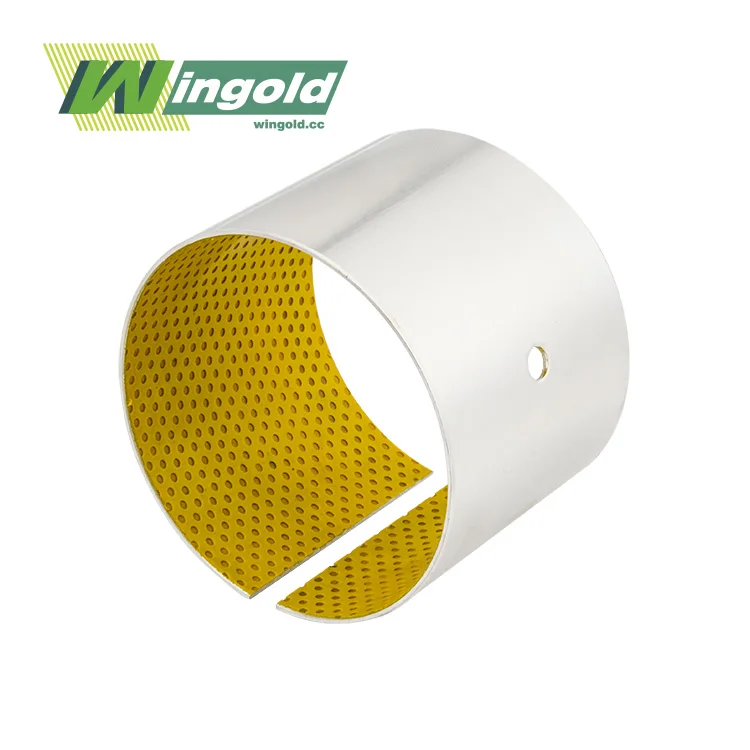

Cast Bronze Bushing

Cast Bronze Bushing: High-Performance Sliding Bearing Solutions

Jiashan Wingold Bearing Co., Ltd. is a leading cast bronze bushing manufacturer and supplier. We excel in providing top-quality, custom-engineered sliding bearing solutions. Our products offer superior performance, durability, and cost-effectiveness, making us the preferred choice for industries worldwide.

Product Description:

Our top - tier products are painstakingly manufactured to adhere to the most stringent industry benchmarks. These multifaceted components are indispensable for a diverse range of applications that demand low frictional properties, substantial load - bearing capabilities, and exceptional wear resistance. Our offerings are engineered to endure harsh operating environments and deliver enduring performance within crucial machinery and equipment.

Specifications:

| Property | Value |

|---|---|

| Material | Cast Bronze (CuSn10Pb10-C) |

| Inner Diameter | 10mm - 500mm |

| Outer Diameter | 12mm - 600mm |

| Length | 10mm - 1000mm |

| Operating Temperature | -40°C to 150°C |

| Load Capacity | Up to 140 N/mm² |

| Friction Coefficient | 0.08 - 0.12 |

Why Choose Us?

- Over 20 years of industry expertise

- Custom-engineered solutions

- State-of-the-art manufacturing facilities

- Rigorous quality control processes

- Competitive pricing and flexible terms

- Global shipping and support

- Commitment to innovation and sustainability

Material:

Our cast bronze bushings are primarily manufactured using CuSn10Pb10-C alloy, known for its excellent mechanical properties and corrosion resistance. This material composition ensures optimal performance in various operating conditions.

Product Advantages:

- Superior Load-Bearing Capacity: Our products excel in high-load applications, making them ideal for heavy machinery and equipment.

- Excellent Wear Resistance: The unique alloy composition provides exceptional durability, minimizing the need for frequent replacements and reducing maintenance costs.

- Low Friction Performance: Our bushings offer smooth operation with minimal friction, enhancing overall equipment efficiency and reducing energy consumption.

- Self-Lubricating Properties: The porous structure of our products allows for oil retention, ensuring consistent lubrication and extended service life.

- Corrosion Resistance: Our bushings demonstrate excellent resistance to corrosive environments, making them suitable for use in challenging industrial settings.

- Thermal Conductivity: Cast bronze's superior heat dissipation properties help maintain optimal operating temperatures, preventing premature wear and failure.

- Customization Options: We offer tailored solutions to meet specific application requirements, ensuring the perfect fit for your unique needs.

Application Areas:

- Automotive Industry: Engine components, suspension systems, steering mechanisms

- Aerospace: Landing gear assemblies, flight control surfaces, actuators

- Marine Equipment: Propeller shafts, rudder bearings, winch systems

- Construction Machinery: Excavators, bulldozers, cranes

- Agricultural Equipment: Tractors, harvesters, irrigation systems

- Material Handling: Conveyor systems, lift trucks, packaging machinery

- Oil and Gas: Drilling equipment, pumps, valves

- Renewable Energy: Wind turbines, solar tracking systems

- Steel Mills: Rolling mill equipment, furnace components

- Paper and Pulp: Paper machines, rollers, presses

Quality Control:

We implement rigorous quality control measures throughout our production process.

Factory related:

Provide suitable bearing products and supporting services according to the needs of different customers

Packaging and Transportation:

We ensure secure packaging and reliable shipping for all orders.

Shipping Samples:

Sample orders are available for testing and evaluation.

Qualification Certification:

We hold ISO 9001 certification for quality management.

Production process related:

Select appropriate raw materials to produce bearing products that meet technical requirements

Exhibitions:

We regularly participate in international trade shows to showcase our products.

FAQ:

-

What is the typical lead time for custom orders?

Our standard lead time for custom orders is 2-4 weeks, depending on the complexity and quantity of the order.

-

Can you provide technical support for product selection?

Yes, our team of engineers is available to assist you in selecting the most suitable product for your application.

-

Are your products compatible with different shaft materials?

Our bushings are designed to work with various shaft materials, including steel, stainless steel, and hardened alloys.

-

What lubrication options are available for your products?

We offer both oil-impregnated and grease-lubricated options, as well as dry-running bushings for specific applications.

-

Do you offer any guarantees or warranties on your products?

Yes, we provide a standard warranty on all our products. Please contact us for detailed warranty information.

Contact Us:

For more information about our cast bronze bushings or to discuss your specific requirements, please contact our sales team at info@wingold.cc. We look forward to providing you with exceptional sliding bearing solutions tailored to your needs.

Learn about our latest products and discounts through SMS or email