Unmatched Corrosion Resistance in Saltwater Environments

One of the primary benefits of custom bronze bushings in marine applications is their exceptional resistance to corrosion. Marine environments are notoriously harsh, with constant exposure to saltwater, humidity, and varying temperatures. These conditions can quickly deteriorate standard materials, leading to premature failure and costly repairs.

Bronze alloys, particularly those used in custom bushings, exhibit remarkable corrosion resistance properties. This resistance stems from the formation of a protective patina on the surface of the bronze, which acts as a barrier against further corrosion. Custom bronze bushings can be engineered with specific alloy compositions to enhance this natural corrosion resistance even further.

Tailored Alloy Composition for Enhanced Protection

When it comes to bronze bushings custom-made for marine use, manufacturers like Wingold can select alloy compositions that provide optimal corrosion resistance. For instance, aluminum bronze alloys, such as SAE 863 (CuAl10Fe5Ni5), offer superior corrosion resistance in seawater environments. These alloys contain elements like aluminum and nickel, which contribute to the formation of a more robust protective layer.

The ability to customize the alloy composition allows for the creation of bushings that not only resist corrosion but also maintain their structural integrity and performance characteristics over time. This customization is crucial in marine applications where component failure can lead to significant downtime and safety risks.

Long-Term Cost Savings Through Corrosion Prevention

While the initial investment in custom bronze bushings may be higher than standard alternatives, the long-term cost savings are substantial. The enhanced corrosion resistance translates to reduced maintenance frequency, fewer replacements, and extended equipment lifespan. In marine environments, where accessibility for maintenance can be challenging and costly, these benefits are particularly valuable.

Moreover, the corrosion resistance of custom bronze bushings contributes to the overall reliability of marine equipment. This reliability is crucial in applications such as offshore platforms, ship propulsion systems, and port machinery, where unexpected failures can result in significant operational disruptions and financial losses.

Superior Load-Bearing Capacity for Heavy-Duty Marine Applications

Another significant advantage of custom bronze bushings in marine environments is their exceptional load-bearing capacity. Marine equipment often operates under extreme conditions, supporting substantial weights and withstanding high pressures. Custom bronze bushings can be engineered to handle these demanding requirements with ease.

The inherent strength of bronze alloys, combined with the ability to tailor the bushing design to specific load requirements, makes bronze bushings custom ideal choice for heavy-duty marine applications. These bushings can maintain their performance characteristics under high loads, even in the presence of shock loads and vibrations common in marine operations.

Customized Design for Optimal Load Distribution

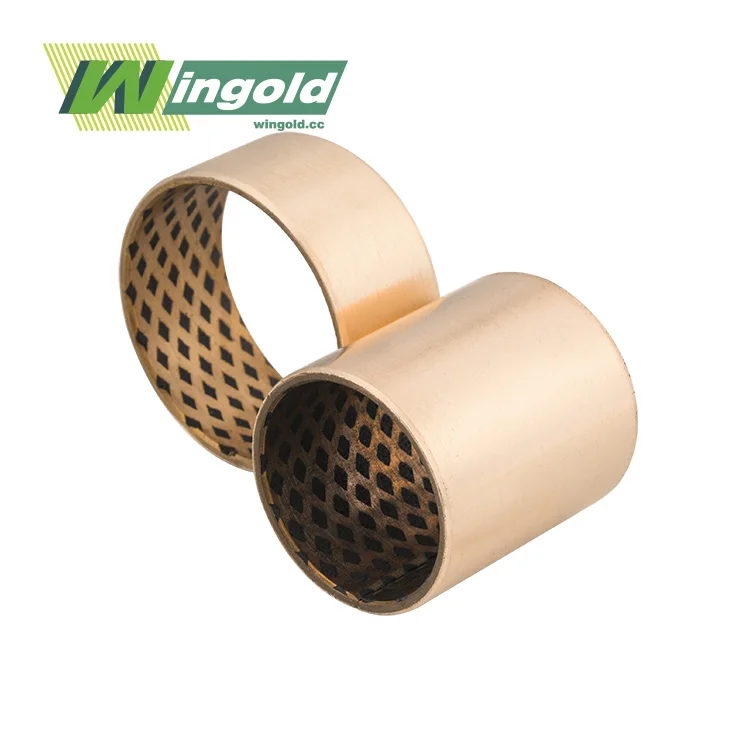

When creating custom bronze bushings for marine use, manufacturers can optimize the design to ensure even load distribution and maximize the bushing's load-bearing capacity. This customization may involve adjusting the wall thickness, incorporating specific surface features, or designing unique geometries that align with the application's load profile.

For example, Wingold's WGB-090 bronze bearings utilize high-density copper alloy strips as the base material. These bearings can be further customized with diamond or hemispherical oil holes and oil grooves, enhancing their load-bearing capacity and wear resistance. This level of customization ensures that the bushings can handle the specific loads encountered in various marine applications, from ship rudder systems to offshore crane bearings.

Maintaining Performance Under Dynamic Loads

Marine environments often subject equipment to dynamic and fluctuating loads. Custom bronze bushings can be designed to maintain their performance under these varying conditions. The natural damping properties of bronze help absorb shocks and vibrations, reducing wear and extending the lifespan of both the bushing and the surrounding components.

Furthermore, the ability to incorporate self-lubricating properties into custom bronze bushings enhances their performance under heavy loads. These self-lubricating characteristics reduce friction and wear, even in boundary lubrication conditions that are common in marine applications where consistent lubrication can be challenging to maintain.

Enhanced Durability and Longevity in Harsh Marine Conditions

The third key benefit of custom bronze bushings in marine environments is their exceptional durability and longevity. Marine applications demand components that can withstand not only corrosion and heavy loads but also abrasive particles, temperature fluctuations, and constant motion. Custom bronze bushings excel in these challenging conditions, offering a combination of wear resistance, thermal stability, and overall robustness.

By utilizing high-performance bronze alloys and tailored designs, custom bushings can significantly outlast standard components, reducing the frequency of replacements and minimizing equipment downtime. This enhanced durability is particularly valuable in marine settings where component accessibility is often limited, and replacement operations can be complex and costly.

Advanced Wear Resistance for Extended Service Life

Bronze bushings custom can be engineered with specific alloy compositions and surface treatments to enhance their wear resistance. For instance, Wingold's expertise in material selection allows for the use of high-performance alloys like C90700 (CuSn10), known for its excellent wear resistance and high load capacity.

Additionally, custom surface treatments and finishes can be applied to further improve wear resistance. These may include hardening processes, the incorporation of solid lubricants, or the creation of specialized surface textures that optimize lubrication and minimize wear. The ability to tailor these features to the specific marine application ensures that the bushings maintain their dimensional stability and performance characteristics over extended periods.

Thermal Stability in Fluctuating Marine Temperatures

Marine environments often subject equipment to significant temperature variations. Custom bronze bushings offer excellent thermal stability, maintaining their dimensional integrity and performance across a wide temperature range. This stability is crucial for maintaining proper clearances and ensuring consistent operation in applications such as marine engines, pumps, and deck machinery.

The thermal conductivity of bronze also contributes to its durability in marine applications. Efficient heat dissipation helps prevent localized overheating, which can lead to premature wear or failure. This characteristic is particularly beneficial in high-speed or high-load applications where heat generation can be substantial.

Conclusion

Bronze bushings custom offers a trifecta of benefits for marine environments: unmatched corrosion resistance, superior load-bearing capacity, and enhanced durability. These advantages translate to improved equipment reliability, reduced maintenance costs, and extended operational lifespans in the challenging conditions of marine applications.

By partnering with experienced manufacturers like Wingold, marine equipment designers and operators can leverage the full potential of custom bronze bushings. Wingold's expertise in material selection, design optimization, and manufacturing processes ensures that each bushing is tailored to meet the specific requirements of its intended marine application.

For more information on how custom bronze bushings can benefit your marine equipment or to discuss your specific application needs, contact Wingold's team of experts at info@wingold.cc. Our commitment to innovation, quality, and customer satisfaction makes us the ideal partner for your marine bushing solutions.

FAQs

What makes bronze bushings suitable for marine environments?

Bronze bushings excel in marine environments due to their corrosion resistance, high load-bearing capacity, and durability in harsh conditions. They form a protective patina against saltwater corrosion and can be customized for specific marine applications.

Can custom bronze bushings reduce maintenance costs in marine equipment?

Yes, custom bronze bushings can significantly reduce maintenance costs by offering extended service life, reduced wear, and improved reliability. Their corrosion resistance and durability mean less frequent replacements and downtime.

How do custom bronze bushings compare to standard bushings in marine use?

Custom bronze bushings outperform standard bushings in marine use by offering tailored solutions for specific applications. They can be designed with optimal alloy compositions, surface treatments, and geometries to meet the unique challenges of marine environments.