Grasping Bronze Self Lubricating Bearings

Bronze self lubricating bearings represent a significant advancement in bearing technology. These ingenious components are crafted from high-quality bronze alloys infused with solid lubricants, creating a unique material composition that offers exceptional performance characteristics. The embedded lubricants form a thin film on the bearing surface during operation, ensuring continuous lubrication without the need for external oil or grease.

The core advantage of bronze self lubricating bearings lies in their ability to maintain optimal lubrication throughout their operational life. This self-lubricating property eliminates the need for regular maintenance and re-lubrication, making them ideal for applications where accessibility is limited or frequent servicing is impractical. Moreover, these bearings boast impressive load-bearing capacities, often exceeding 140 MPa, which allows them to withstand substantial forces without compromising performance.

Another notable feature of bronze self lubricating bearings is their remarkable temperature tolerance. Capable of operating efficiently within a temperature range of -40°C to 150°C, these bearings maintain their structural integrity and lubricating properties across diverse environmental conditions. This wide operational range makes them suitable for use in various industries, from automotive and aerospace to heavy machinery and marine applications.

Composition and Manufacturing Process

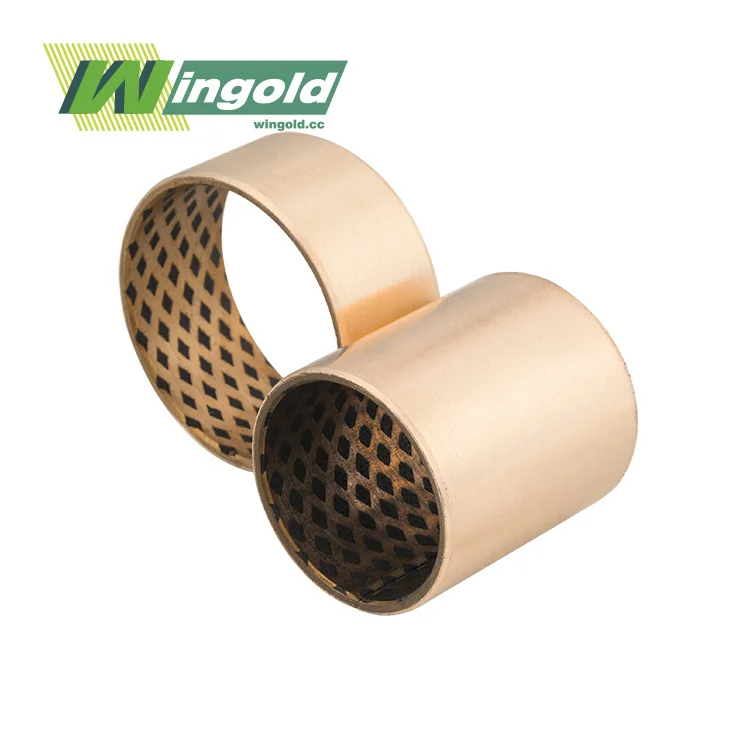

The manufacturing process of bronze self lubricating bearings involves sophisticated techniques to ensure optimal performance. High-density copper alloy strips form the base material, which undergoes a meticulous fabrication process. The surface of these bearings can be customized with diamond or hemispherical oil holes and oil grooves, tailored to specific user requirements. This customization enhances the bearing's ability to retain lubricant and distribute it evenly across the bearing surface during operation.

The incorporation of solid lubricants into the bronze matrix is a critical step in the manufacturing process. These lubricants, typically graphite or PTFE, are uniformly distributed throughout the bearing material. During operation, the friction between the bearing and the shaft causes these lubricants to migrate to the surface, forming a thin, low-friction film that continuously replenishes itself as it wears away.

Performance Characteristics

Bronze self lubricating bearings exhibit exceptional performance characteristics that set them apart in the world of bearing technology. Their low friction coefficient, typically ranging from 0.05 to 0.15, results in reduced energy consumption and heat generation during operation. This low friction, coupled with the continuous self-lubrication, contributes to a remarkably low wear rate of less than 5 µm/km, ensuring extended service life and reduced maintenance requirements.

The high load capacity of these bearings makes them suitable for demanding applications in industries such as construction machinery, automotive, and mining. Their ability to withstand high loads while maintaining low friction and wear rates translates to improved efficiency and reliability in mechanical systems. Furthermore, the inherent corrosion resistance of bronze alloys enhances the durability of these bearings, particularly in environments exposed to moisture or corrosive agents.

Oil Impregnated Bronze Bearings: A Comparative Analysis

Oil impregnated bronze bearings, while sharing some similarities with their self lubricating counterparts, operate on a different principle. These bearings are manufactured by impregnating porous bronze with oil under high pressure. During operation, the heat generated causes the oil to expand and form a lubricating film on the bearing surface. While effective in certain applications, oil impregnated bearings have limitations that are important to consider.

One of the primary differences between oil impregnated and self lubricating bronze bearings is the longevity of their lubricating properties. Oil impregnated bearings rely on a finite reservoir of oil within their porous structure. Over time, this oil can be depleted, necessitating re-oiling or replacement of the bearing. In contrast, self lubricating bearings with embedded solid lubricants continue to provide lubrication throughout their operational life, offering a more sustainable and maintenance-free solution.

Load Capacity and Operating Conditions

When it comes to load-bearing capacity, bronze self lubricating bearings generally outperform their oil impregnated counterparts. The solid lubricants embedded in self lubricating bearings allow for higher load capacities without compromising lubrication efficiency. Oil impregnated bearings, while suitable for moderate loads, may struggle under high-stress conditions, potentially leading to premature failure or increased maintenance requirements.

Operating temperature range is another crucial factor to consider. Self lubricating bronze bearings, with their wide temperature tolerance (-40°C to 150°C), offer superior performance across diverse environmental conditions. Oil impregnated bearings, however, may face limitations at extreme temperatures. High temperatures can cause the impregnated oil to break down or evaporate, while low temperatures might increase oil viscosity, potentially affecting bearing performance.

Maintenance and Longevity

The maintenance requirements for these two types of bearings differ significantly. Self lubricating bronze bearings, once installed, require minimal to no maintenance throughout their operational life. This characteristic makes them particularly valuable in applications where regular maintenance is challenging or costly. Oil impregnated bearings, on the other hand, may require periodic re-oiling to maintain their lubricating properties, especially in high-use or high-temperature applications.

In terms of longevity, self lubricating bearings often have the edge. Their continuous self-lubricating properties and lower wear rates contribute to an extended service life, reducing the frequency of replacements and associated downtime. While oil impregnated bearings can offer satisfactory performance in less demanding applications, they may not match the long-term reliability and consistency of self lubricating bearings in more challenging environments.

Choosing the Right Bearing for Your Application

Selecting between self lubricating and oil impregnated bronze bearings requires careful consideration of your specific application requirements. Several key factors should guide your decision-making process to ensure optimal performance and longevity of your mechanical system.

Load requirements play a crucial role in bearing selection. For applications involving high loads or frequent load fluctuations, self lubricating bronze bearings are often the superior choice. Their ability to maintain a consistent lubricating film under high stress makes them ideal for heavy-duty machinery, construction equipment, and automotive applications. Oil impregnated bearings may suffice for lighter loads and more stable operating conditions, such as in small appliances or low-speed rotary equipment.

Environmental Considerations

The operating environment is another critical factor in bearing selection. Bronze self lubricating bearings excel in harsh environments where exposure to dust, moisture, or corrosive agents is common. Their ability to operate across a wide temperature range makes them suitable for outdoor applications or industries with varying environmental conditions. Oil impregnated bearings, while effective in controlled environments, may struggle in extreme temperatures or contaminated settings where the oil film can be compromised.

Consider the accessibility of the bearing for maintenance purposes. In applications where regular maintenance is impractical or costly, such as in hard-to-reach locations or continuous operation systems, self lubricating bearings offer a significant advantage. Their maintenance-free nature eliminates the need for periodic lubrication, reducing downtime and maintenance costs. Oil impregnated bearings might be suitable for easily accessible applications where regular maintenance is not a concern.

Long-term Cost and Performance Analysis

When evaluating the cost-effectiveness of bearing options, it's essential to consider both initial investment and long-term operational costs. While self lubricating bronze bearings may have a higher upfront cost, their extended service life, reduced maintenance requirements, and consistent performance often result in lower total cost of ownership over time. Oil impregnated bearings, despite potentially lower initial costs, may incur additional expenses related to maintenance, re-lubrication, and more frequent replacements.

Performance stability is another crucial consideration. Self lubricating bearings maintain consistent performance characteristics throughout their operational life, ensuring reliable operation and predictable maintenance schedules. Oil impregnated bearings may exhibit performance variations as the oil reservoir depletes, potentially leading to unexpected maintenance needs or performance issues.

Conclusion

In the debate between self lubricating and oil impregnated bronze bearings, the choice ultimately depends on the specific requirements of your application. Self lubricating bronze bearings offer superior performance, longevity, and reliability, particularly in demanding environments and high-load applications. Their maintenance-free nature and consistent performance make them an excellent choice for a wide range of industries and applications.

While oil impregnated bearings have their place in certain low-load, easily accessible applications, the advantages of self lubricating bearings often outweigh their limitations. As technology continues to advance, the gap in performance and efficiency between these two bearing types is likely to widen further.

For those seeking cutting-edge bearing solutions that offer unparalleled performance and reliability, Wingold Bearing stands at the forefront of bronze self lubricating bearing technology. Our expertise in sliding bearing solutions, coupled with our commitment to innovation and quality, ensures that we can provide the ideal bearing solution for your specific needs. To explore how our advanced bearing technology can enhance your applications, don't hesitate to reach out to us at info@wingold.cc

.

FAQ

What are the main advantages of bronze self lubricating bearings?

Bronze self lubricating bearings offer continuous lubrication without external oils, high load capacity, wide temperature tolerance, low friction, and minimal maintenance requirements.

How long do self lubricating bronze bearings typically last?

The lifespan of self lubricating bronze bearings varies depending on the application, but they generally offer extended service life due to their low wear rate and consistent lubrication properties.

Can self lubricating bearings be used in high-temperature environments?

Yes, many self lubricating bronze bearings can operate efficiently in temperatures ranging from -40°C to 150°C, making them suitable for high-temperature applications.

Are bronze self lubricating bearings environmentally friendly?

Yes, these bearings are considered environmentally friendly as they eliminate the need for external lubricants, reducing the risk of oil leaks and contamination.