Understanding Oil Pump Bushings and Their Function

Oil pump bushings are essential components in the intricate machinery of oil pumps. These cylindrical bearings serve as interfaces between moving parts, facilitating smooth operation and minimizing friction. Let's delve deeper into the nature and function of oil pump bushings:

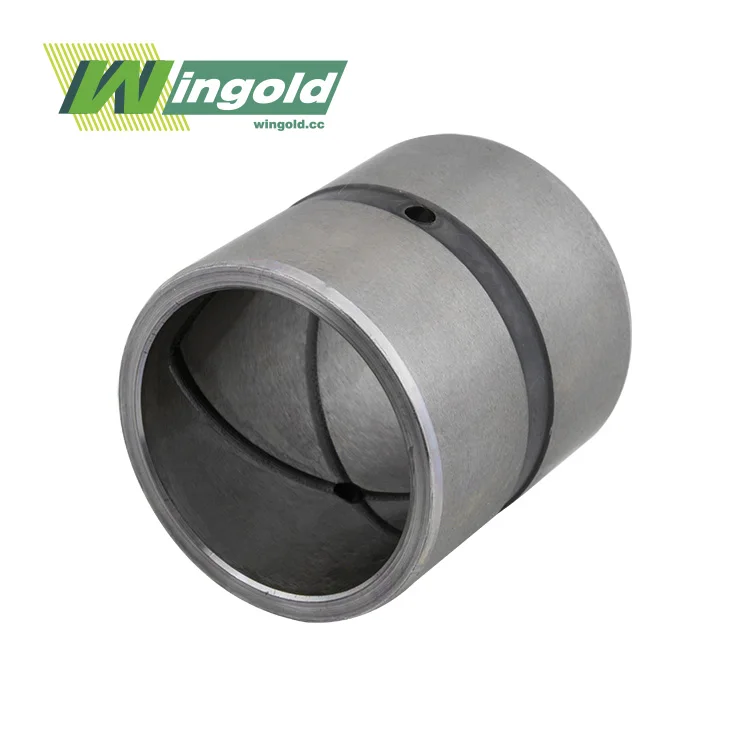

What Are Oil Pump Bushings?

Oil pump bushings are precision-crafted cylindrical components typically made from materials such as bronze, babbitt, or custom alloys. These bushings are designed to withstand high pressures, temperatures, and continuous operation in challenging environments. The dimensions of oil pump bushings can vary significantly, with inner diameters ranging from 10mm to 500mm, outer diameters from 15mm to 600mm, and lengths from 10mm to 1000mm.

The Role of Bushings in Oil Pump Operations

In oil pump systems, bushings serve several critical functions:

- Alignment: Bushings ensure proper alignment of rotating shafts and other moving components within the pump.

- Friction Reduction: By providing a low-friction interface, bushings minimize energy loss due to friction between moving parts.

- Load Distribution: Bushings help distribute loads evenly, reducing wear and extending the lifespan of pump components.

- Clearance Control: Maintaining optimal clearance between moving parts is crucial for pump efficiency, and bushings play a key role in this aspect.

Materials and Design Considerations

The choice of materials and design for oil pump bushings significantly impacts their performance. Bronze bushings are popular due to their excellent wear resistance and load-bearing capacity. Babbitt-lined bushings offer superior conformability and embedability, making them suitable for high-load applications. Custom alloys can be formulated to meet specific requirements of temperature resistance, corrosion resistance, or other performance criteria.

Advanced engineering techniques, such as those employed by Wingold Bearing, optimize bushing performance under various operating conditions. These techniques include precision manufacturing to tight tolerances (following ISO 286-2 standards) and achieving superior surface finishes (Ra 0.1 - 0.8 μm).

How Oil Pump Bushings Influence Pump Efficiency?

The impact of oil pump bushings on overall pump efficiency is multifaceted. Let's explore the key ways in which these components contribute to enhanced pump performance:

Friction Reduction and Energy Savings

One of the primary functions of oil pump bushings is to minimize friction between moving parts. High-quality bushings, such as those manufactured by Wingold Bearing, feature precisely engineered surfaces and tight tolerances. This results in reduced friction, which translates directly into energy savings. Lower friction means less power is required to operate the pump, leading to improved overall efficiency and reduced energy consumption.

Maintaining Optimal Clearances

Proper clearance between moving parts is crucial for pump efficiency. Oil pump bushings play a vital role in maintaining these clearances, ensuring that components move freely without excessive play. This optimal clearance contributes to smoother operation, reduced wear, and improved pumping efficiency. The ability of bushings to maintain these clearances over time, even under challenging operating conditions, is a key factor in sustaining long-term pump performance.

Wear Resistance and Longevity

The durability of oil pump bushings directly impacts the longevity and consistent performance of the pump. High-quality bushings, such as those offered by Wingold Bearing, demonstrate exceptional resistance to wear, corrosion, and fatigue. This enhanced durability means less frequent replacements, reduced downtime, and more consistent pump efficiency over time. The ability to withstand tough conditions ensures that the pump maintains its optimal performance for extended periods, even in demanding industrial applications.

Advancements in Oil Pump Bushing Technology

The field of oil pump bushing technology is continually evolving, with innovations aimed at further improving pump efficiency and reliability. Let's examine some of the recent advancements and their implications:

Self-Lubricating Bushings

One of the significant developments in bushing technology is the advent of self-lubricating bushings. These innovative components, like those offered by Wingold Bearing, incorporate materials or designs that provide lubrication without the need for external lubricants. This technology offers several advantages:

- Reduced Maintenance: Self-lubricating bushings require less frequent maintenance, reducing downtime and operational costs.

- Environmental Benefits: By eliminating the need for external lubricants, these bushings contribute to a cleaner operating environment.

- Consistent Performance: The self-lubricating feature ensures consistent performance over time, maintaining pump efficiency even in challenging conditions.

Advanced Materials and Coatings

The development of new materials and coatings has significantly enhanced the performance of oil pump bushings. These advancements include:

- Composite Materials: Engineered composites offer improved wear resistance and lower friction coefficients compared to traditional materials.

- Nano-coatings: Ultra-thin coatings at the nanoscale can dramatically improve surface properties, enhancing wear resistance and reducing friction.

- Bimetallic Bushings: Combining different metals or alloys in a single bushing can optimize performance for specific operating conditions.

Precision Manufacturing Techniques

Advancements in manufacturing technologies have enabled the production of oil pump bushings with unprecedented precision. These techniques include:

- CNC Machining: Computer-controlled machining allows for extremely tight tolerances and complex geometries.

- 3D Printing: Additive manufacturing techniques open up new possibilities for customized bushing designs and materials.

- Surface Finishing: Advanced surface treatment methods can achieve ultra-smooth finishes, further reducing friction and improving efficiency.

Conclusion

Oil pump bushings play a pivotal role in determining the efficiency, reliability, and longevity of oil pump systems. By providing proper alignment, reducing friction, and maintaining optimal clearances, these components contribute significantly to overall pump performance. As technology continues to advance, innovations in materials, design, and manufacturing techniques are further enhancing the capabilities of oil pump bushings.

For businesses and industries relying on oil pump systems, investing in high-quality bushings is a strategic decision that can lead to substantial benefits in terms of energy savings, reduced maintenance costs, and improved operational efficiency. Companies like Wingold Bearing are at the forefront of this technology, offering customized solutions that meet the specific needs of various applications.

To learn more about how advanced oil pump bushings can enhance your pump efficiency and overall system performance, contact Wingold Bearing at info@wingold.cc. Our team of experts is ready to provide tailored solutions that can make a significant impact on your operations.

FAQ

How often should oil pump bushings be replaced?

The replacement frequency depends on factors such as operating conditions, pump usage, and bushing quality. High-quality bushings can last several years under normal conditions.

Can oil pump bushings be customized for specific applications?

Yes, companies like Wingold Bearing offer customized bushing solutions tailored to specific operating requirements and pump designs.

What are the signs that oil pump bushings need replacement?

Signs include increased noise, vibration, reduced pump efficiency, and visible wear on the bushings or related components.