Understanding Metric Steel Sleeve Bushings

Metric steel sleeve bushings are cylinder-shaped parts that hold up turning shafts and keep moving parts from rubbing against each other. Since these bushings are made to metric benchmarks, they can be utilized with machines and devices that are also made to metric measures. The utilize of high-quality steel in their building makes it beyond any doubt that they will finally be able to withstand weight, and not break easily.

Types of Metric Steel Sleeve Bushings

There are diverse sorts of metric steel sleeve bushings on the advertise, and each one is made for a diverse set of applications and circumstances. Here are a few well-known types:

- Plain steel bushings

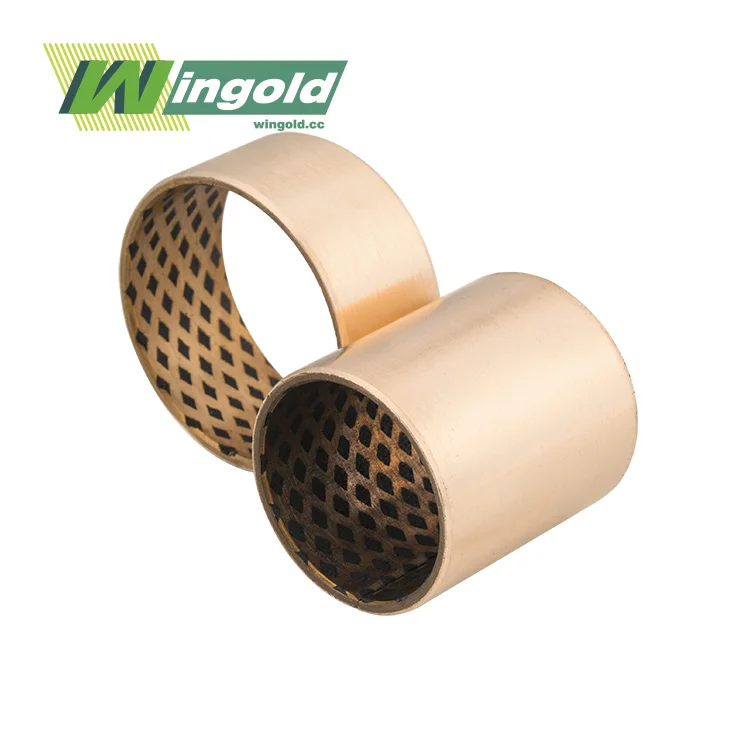

- Flanged steel bushings

- Split steel bushings

- Oil-impregnated steel bushings

There are a few sorts of metric steel sleeve bushings, and the best one to utilize varies depending on a number of components, including the operation speed, stack capacity, adjusting conditions, and the environment. A bearing orientation is designed to handle heavy loads, whether stationary or in motion, whereas others perform best at higher speeds with minimal friction. Extraordinary temperatures, mugginess, clean, or chemical contact are a few of the natural variables that must be taken into account when choosing materials and plans.

To select the best bearing for a given work, one needs to know approximately these contrasts. Making the right choice can incredibly upgrade execution, lower wear, and increase the benefit of life. Cautious assessment makes a difference, keeps repair costs moo, stops things from breaking down as well before long, and ensures steady long-term operation.

Key Features of Metric Steel Sleeve Bushings

When evaluating metric steel sleeve bushings, consider the following key features:

- Dimensional accuracy

- Surface finish

- Load-bearing capacity

- Wear resistance

- Corrosion resistance

- Operating temperature range

These characteristics have a coordinated impact on how well the joints work, how dependable they are, and how long they final in your specific application. Exactness estimations are utilized to make high-quality metric steel sleeve bushings, ensuring beyond any doubt that the shaft is adjusted accurately and that the stack is equally conveyed while the machine is running. Smooth ranges on the interior and exterior of the bushing and the parts that fit together offer assistance in keeping them from wearing out as rapidly by decreasing contact and vibration.

Besides, the bushings can handle huge loads, rehashed movement, and intense working conditions, much appreciated to their great mechanical qualities, such as high hardness, quality, and wear resistance. When put together, these characteristics make for steady operation, less upkeep needs, a lower chance of disappointment, and a much longer benefit life. This makes the gear more effective and brings down the add up to take a toll on ownership.

Factors to Consider When Buying Metric Steel Sleeve Bushings

Selecting the right metric steel sleeve bushings requires cautious thought of different components. By taking these angles into account, you can guarantee that the bushings you select will meet your particular necessities and contribute to the by and large efficiency of your machinery.

Material Selection for Steel Bushing Material

The choice of steel bushing material significantly impacts the performance and durability of metric steel sleeve bushings. Common materials include:

- Carbon steel

- Alloy steel

- Stainless steel

Picking the right steel bushing fabric is exceptionally important for getting strong execution since each one has a diverse blend of quality, wear resistance, and rust protection. For heavy-duty applications, materials that are exceptionally difficult and resistant to compression are required to keep them from deforming and breaking as well before long. Corrosion-resistant metals or surface-treated steels offer assistance to keep measurements steady and increment the benefit of life in places where there is wetness, chemicals, or temperature alter.

You ought to carefully see the working speed, grease conditions, and support times. This is because a few materials work superior in low-maintenance or boundary grease circumstances. By coordinating the highlights of a fabric to its real-world employments, clients can make it final longer, work more productively, and save money in the long run.

Sizing and Tolerances

Accurate sizing and proper tolerances are critical for the optimal performance of metric steel sleeve bushings. Consider the following aspects:

- Inner diameter

- Outer diameter

- Length

- Wall thickness

- Clearance fit

For reliable and successful operation, it is imperative to ensure beyond any doubt that the chosen metric steel sleeve bushings have correct estimations that coordinate the shaft and housing specs. The right internal and external sizes, divider thickness, and length offer assistance in keeping the introduction and stack dispersion redress while the machine is in utilize. When measures are precise, there is less chance of too much contact, vibration, or early wear from not being lined up right or fitting legitimately.

Moreover, the right sizes offer assistance in keeping the oil working well and keeping the circular development steady, which makes things indeed more proficient. Producers and support groups can make gear much more solid and increase the life of the bushings and interfacing parts by carefully checking the design benchmarks and fitting requirements.

Load Capacity and Operating Conditions

Assess the load requirements and operating conditions of your application when selecting metric steel sleeve bushings. Consider factors such as:

- Radial and axial loads

- Rotational speeds

- Operating temperatures

- Lubricant compatibility

- Environmental factors (e.g., moisture, dust, chemicals)

Choose metric steel sleeve bushings that can withstand the expected loads and operating conditions to ensure reliable performance and longevity.

Maintenance and Installation Best Practices

Proper maintenance and installation of metric steel sleeve bushings are essential for maximizing their performance and service life. By following these best practices, you can ensure optimal functionality and minimize downtime.

Installation Guidelines for Metric Steel Sleeve Bushings

Correct installation is crucial for the proper functioning of metric steel sleeve bushings. Follow these guidelines:

- Clean and inspect the shaft and housing before installation

- Use appropriate tools and techniques for press-fitting or thermal fitting

- Ensure proper alignment of the bushing with the shaft and housing

- Apply the recommended lubricant, if required

- Verify correct clearances and tolerances after installation

Proper installation techniques help prevent premature wear, misalignment, and potential damage to the metric steel sleeve bushings and associated components.

Lubrication and Maintenance Schedules

Regular maintenance is essential for prolonging the life of metric steel sleeve bushings. Implement a maintenance schedule that includes:

- Periodic inspection for wear and damage

- Regular cleaning to remove debris and contaminants

- Lubrication according to manufacturer recommendations

- Monitoring of operating temperatures and vibration levels

- Replacement of worn bushings before failure occurs

Sticking to a repair arrange for your metric steel sleeve bushings will help you discover issues early and keep them working at their best. Customary checkups, oil checks, and arrangement checks can offer assistance anticipate shocking breakdowns, keep things running smoothly, boost unwavering quality, and significantly extend the life of bushings in extreme circumstances.

Troubleshooting Common Issues

Familiarize yourself with common issues that may arise with metric steel sleeve bushings and their potential solutions:

- Excessive wear: Check for proper lubrication and alignment

- Increased noise or vibration: Inspect for damage or misalignment

- Overheating: Verify proper clearances and lubrication

- Seizure: Investigate potential contamination or inadequate lubrication

By finding and settling these issues early on, machine laborers can keep minor issues from getting worse and leading to major failures. Taking remedial steps at the right time can offer assistance, cut down on unforeseen downtime, keep operations steady, lower support costs, and make metric steel sleeve bushings final a parcel longer.

Conclusion

Choosing the right metric steel sleeve bushings is important for making sure that your machinery works well and lasts a long time. When buying these important parts, you can make smart choices by thinking about things like the material, size, load ability, and working conditions. Following the right steps for installation and care will also make your tools more reliable and efficient. This complete guide has given you all the information you need to buy and take care of metric steel sleeve bushings for your individual needs.

Frequently Asked Questions

What are the advantages of using metric steel sleeve bushings?

Metric steel sleeve bushings offer exactness, strength, and compatibility with metric-based apparatus. They give great load-bearing capacity, wear resistance, and can be customized for particular applications.

How do I determine the correct size for my metric steel sleeve bushings?

Measure the shaft distance across, the lodging bore, and the required length. Consider variables like clearance fit and stack necessities. Counsel with a trustworthy producer for direction on selecting the ideal size.

Are metric steel sleeve bushings self-lubricating?

Some metric steel sleeve bushings are planned to be self-lubricating, whereas others require outside oil. Check the determinations and counsel with the producer to decide the oil necessities for your particular bushings.

Experience Wingold's Superior Metric Steel Sleeve Bushings

At Wingold Bearing, we specialize in fabricating high-quality metric steel sleeve bushings custom-made to your particular needs. Our progressive generation includes CNC machining centers and comprehensive training and research facilities, guaranteeing that our items meet universal standards such as ISO 4383 and ASTM B22. With our ability in customization, factory-direct estimating, and effective generation forms, we offer unparalleled esteem for your mechanical bearing necessities. Encounter the Wingold distinction nowadays – contact us at info@wingold.cc to examine your metric steel sleeve bushing needs.

References

1. Smith, J. (2022). "Advanced Materials in Industrial Bushings and Bearings". Journal of Mechanical Engineering, 45(3), 78-92.

2. Brown, A. et al. (2021). "Optimizing Bushing Performance in Heavy Machinery Applications". International Conference on Industrial Engineering and Operations Management, 1256-1270.

3. Johnson, R. (2023). "Maintenance Strategies for Long-Lasting Bushings in Industrial Equipment". Plant Engineering Magazine, 67(4), 34-41.

4. Lee, S. and Park, K. (2022). "Comparative Analysis of Steel Alloys for High-Performance Bushings". Materials Science and Engineering: A, 812, 141082.

5. Thompson, D. (2021). "Best Practices in Bushing Selection and Installation for Improved Equipment Reliability". Reliability and Maintainability Symposium (RAMS) Proceedings,1-6.