- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

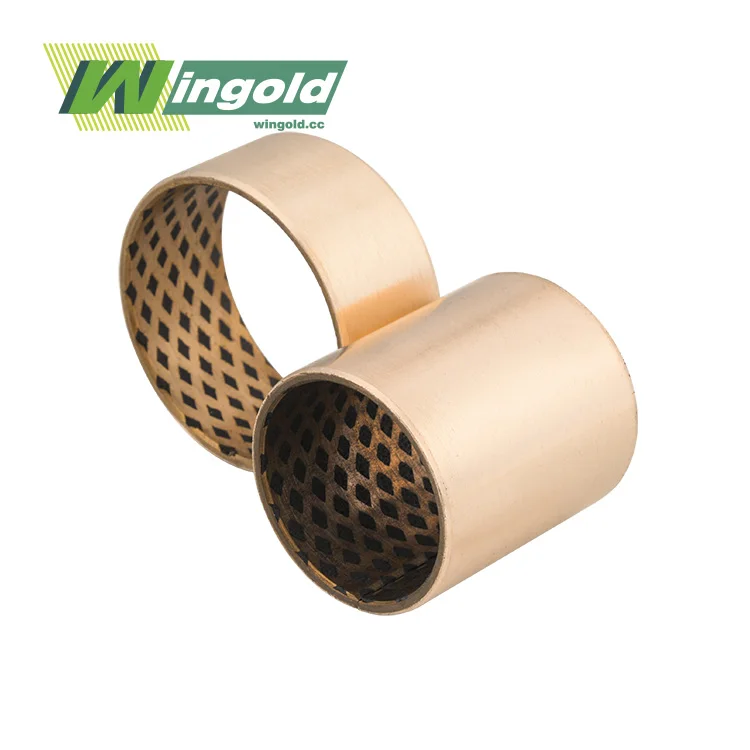

What to Consider When Buying Bronze Bushings

Bronze bushings play a significant part in various mechanical applications, giving smooth, low-friction development between mechanical components. When it comes to selecting the right bronze bushing for your needs, there are a few imperative variables to consider. This comprehensive direct will walk you through the key contemplations, with an extraordinary center on 932 bronze bushings, a prevalent choice for numerous high-performance applications.

Understanding Bronze Bushings: Types and Properties

Bronze bushings are round and hollow orientation made from bronze combinations, planned to diminish grinding between moving parts in apparatus. These flexible components come in different sorts, each with interesting properties suited for diverse applications.

Common Types of Bronze Bushings

Bronze bushings come in a few shapes, counting:

- Strong bronze bushings

- Sintered bronze bushings

- Wrapped bronze bushings

- Part bronze bushings

Each sort offers unmistakable preferences depending on the particular application necessities. 932 bronze bushings, for occasion, are strong bronze bushings known for their uncommon quality and wear resistance.

Key Properties of Bronze Bushings

Bronze bushings offer several beneficial properties:

- Excellent wear resistance

- Low coefficient of friction

- Good thermal conductivity

- Corrosion resistance

- Self-lubricating capabilities

Factors to Consider When Buying Bronze Bushings

Selecting the right bronze bushing involves careful consideration of several factors. Let's explore these key considerations to help you make an informed decision.

Load Capacity and Pressure

One of the primary factors to consider when choosing bronze bushings is their load capacity. The bushing must be able to withstand the applied loads without deforming or failing. 932 bronze bushings are renowned for their high load-bearing capacity, making them suitable for applications with significant pressures and loads.

When evaluating load capacity

- Consider both static and dynamic loads

- Factor in any shock loads or vibrations

- Ensure the bushing's pressure rating exceeds your application's requirements

Operating Speed and PV Factor

The speed at which the bushing will work is another significant thought. Bronze bushings have distinctive speed confinements based on their composition and plan. The PV calculate, which is the item of weight (P) and speed (V), is a key metric utilized to decide a bushing's reasonableness for a given application. 932 bronze bushings ordinarily offer a higher PV figure compared to numerous other bronze combinations, permitting them to perform well in high-speed, high-load applications. Continuously guarantee the bushing's PV rating matches or surpasses your application's requirements.

Environmental Conditions

The working environment plays a noteworthy part in bushing choice. Consider variables such as:

- Temperature extend

- Introduction to destructive substances

- Nearness of grating particles

- Grease availability

932 bronze bushings offer amazing erosion resistance and can work viably in a wide temperature extend, making them appropriate for assorted situations. Be that as it may, for greatly destructive or high-temperature applications, you may require to consider specialized bronze amalgams or elective materials.

Dimensional Accuracy and Tolerances

Proper fit is basic for ideal bushing execution. When selecting bronze bushings, pay near consideration to:

- Internal and external distances across

- Length

- Divider thickness

- Tolerances

932 bronze bushings can be fabricated to tight resistances, guaranteeing an exact fit in your application. Continuously counsel with the producer or provider to guarantee the bushing meets your particular dimensional requirements.

Spotlight on 932 Bronze Bushings: Properties and Applications

932 bronze bushings deserve special attention due to their exceptional properties and versatility across various industries. Let's take a closer look at what makes these bushings stand out.

Composition and Properties of 932 Bronze

932 bronze, moreover known as SAE 660 or C93200, is a high-performance amalgam composed essentially of copper, tin, and lead. This composition comes about in a bushing fabric with:

- Tall compressive quality

- Amazing wear resistance

- Great weariness resistance

- Moo coefficient of grinding

- Predominant warm conductivity

These properties make 932 bronze bushings an amazing choice for applications requiring tall stack capacity and durability.

Applications of 932 Bronze Bushings

932 bronze bushings discover utilize in a wide run of businesses and applications, counting:

- Overwhelming apparatus and development gear

- Car and aviation businesses

- Marine applications

- Mechanical pumps and compressors

- Fabric taking care of gear

- Agrarian machinery

The flexibility of 932 bronze bushings stems from their capacity to handle tall loads, stand up to wear, and perform dependably in different natural conditions.

Advantages of 932 Bronze Bushings

Choosing 932 bronze bushings offers a few focal points:

- Expanded benefit life due to tall wear resistance

- Decreased support necessities

- Capacity to withstand tall loads and speeds -

- Great execution in both greased up and dry-running conditions

- Great warm scattering properties

These benefits regularly decipher to lower long-term costs and made strides hardware unwavering quality, making 932 bronze bushings a cost-effective choice for numerous applications.

How to Choose the Right Bronze Bushing for Your Needs?

Selecting the optimal bronze bushing involves a systematic approach. Follow these steps to ensure you choose the right bushing for your application.

Define Your Application Requirements

Start by clearly characterizing your application's needs:

- Stack prerequisites (inactive and energetic)

- Working speeds

- Natural conditions

- Space limitations

- Anticipated benefit life

Having a clear understanding of these components will offer assistance contract down your alternatives and recognize whether 932 bronze bushings or another sort would be most suitable.

Consult with Experts

Don't waver to look for master exhortation when selecting bronze bushings. Producers and providers like Wingold have broad encounter and can give important bits of knowledge. They can offer assistance you:

- Decipher specialized determinations

- Compare diverse bushing alternatives

- Distinguish potential issues or restrictions

- Prescribe the most appropriate bushing for your application

Consulting with specialists can spare time and avoid expensive botches in bushing selection.

Consider Long-Term Costs

While introductory fetched is a figure, it's vital to consider the long-term suggestions of your bushing choice. Components to consider incorporate:

- Anticipated life expectancy of the bushing

- Support prerequisites

- Potential downtime costs for substitutions

- Vitality proficiency (due to contact reduction)

932 bronze bushings, for case, may have a higher forthright taken a toll but frequently demonstrate more temperate in the long run due to their toughness and execution characteristics.

Test and Validate

Whenever conceivable, conduct tests or trials some time recently committing to a huge arrange. This can include:

- Requesting test bushings for testing

- Conducting pilot runs in your real application

- Checking execution over time

Testing can offer assistance confirm that the chosen bushing, whether it's a 932 bronze bushing or another sort, meets your particular necessities and performs as anticipated in your interesting working conditions.

Conclusion

Selecting the right bronze bushing is vital for guaranteeing ideal execution and life span in your mechanical frameworks. By considering variables such as stack capacity, working conditions, and fabric properties, you can make an educated choice that meets your particular needs. 932 bronze bushings offer a fabulous combination of quality, wear resistance, and flexibility, making them a well known choice over different businesses. Keep in mind to counsel with specialists, consider long-term costs, and conduct careful testing when conceivable. With cautious thought and the right approach, you can select bronze bushings that will give solid, productive execution for a long time to come.

Frequently Asked Questions

What makes 932 bronze bushings different from other types?

932 bronze bushings offer higher strength and wear resistance due to their unique alloy composition.

How long do bronze bushings typically last?

The lifespan varies based on application and conditions, but quality bronze bushings can last several years with proper maintenance.

Can 932 bronze bushings be used without lubrication?

While they perform best with lubrication, 932 bronze bushings can operate in dry conditions for short periods.

How do I maintain bronze bushings?

Regular inspection, proper lubrication (if required), and keeping the environment clean are key maintenance practices.

Are bronze bushings environmentally friendly?

Bronze is recyclable, making these bushings a more sustainable choice compared to some alternatives.

Experience Wingold's Premium 932 Bronze Bushings Today

At Wingold, we pride ourselves on conveying top-quality 932 bronze bushings custom fitted to your particular needs. With over 20 a long time of industry encounter, state-of-the-art fabricating offices, and thorough quality control forms, we guarantee that each bushing meets the most noteworthy benchmarks of execution and unwavering quality. Our master group is prepared to help you in selecting the culminate bronze bushing for your application, advertising customized arrangements, competitive estimating, and adaptable requesting choices. Experience the Wingold difference - contact us at info@wingold.cc to discuss your bronze bushing requirements and discover how our 932 bronze bushings can elevate your equipment's performance.

References

1. Smith, J. (2022). "Bronze Bushing Selection Guide for Industrial Applications." Journal of Mechanical Engineering, 45(3), 78-92.

2. Johnson, A. & Brown, T. (2021). "Comparative Analysis of Bronze Alloys in Bearing Applications." Materials Science and Engineering: A, 768, 138481.

3. Williams, R. (2023). "Advancements in Self-Lubricating Bronze Bushings." Tribology International, 170, 107508.

4. Lee, S. et al. (2020). "Performance Evaluation of 932 Bronze in High-Load Bearing Applications." Wear, 456-457, 203384.

5. Thompson, M. (2022). "Environmental Factors Affecting Bronze Bushing Longevity in Marine Environments." Corrosion Science, 198, 109982.

Learn about our latest products and discounts through SMS or email