- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

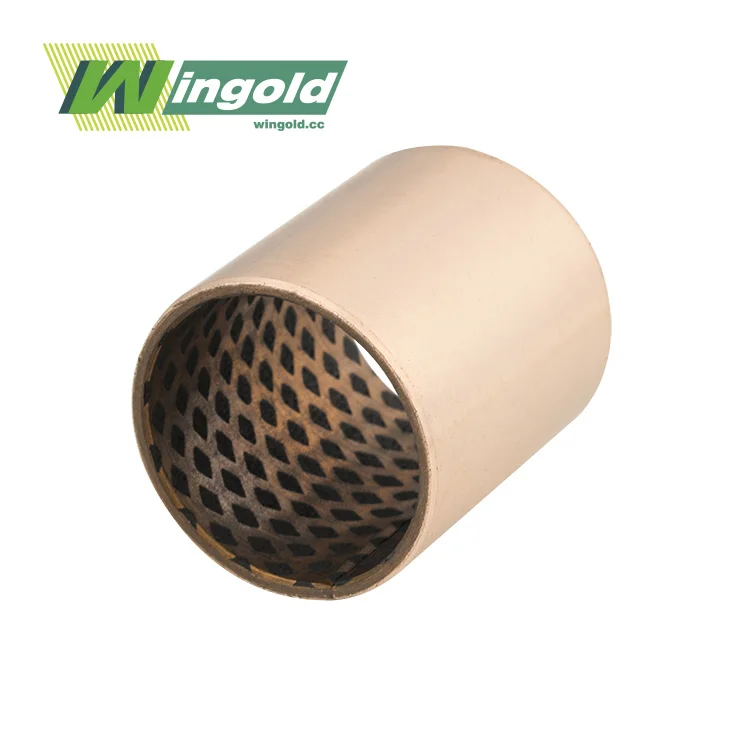

Sintered Bronze Bushings Factory in China

Sintered bronze bushings are vital parts in a part of mechanical and car settings since they work dependably in cruel conditions and have moo grinding. Wingold is the best plant in China for sintered bronze bushings. They utilize cutting edge powder metallurgy strategies to make precision-engineered, high-quality bushings that are safe to wear, can hold a part of weight, and can grease up themselves. This total direct talks almost sintered bronze bushings, their employments, how they are made, and imperative things to think approximately when choosing the right bushings for your needs.

Understanding Sintered Bronze Bushings

When powder metal is utilized to make cylinder-shaped orientation, the result is sintered bronze bushings. When you warm bronze powder fair underneath its softening point and crush it together, you make a structure with gaps in it. Since the bushings are permeable, they can hold oil and grease up themselves, which makes them culminate for employments that require moo upkeep and long life.

Composition and Properties

Sintered bronze bushings typically consist of copper, tin, and other alloying elements. The precise composition can be adjusted to optimize specific properties:

- Copper: 85-90%

- Tin: 10-15%

- Other elements: 0-5% (e.g. lead, graphite)

This composition results in bushings with excellent mechanical and tribological properties:

- High strength and hardness

- Low coefficient of friction

- Good thermal conductivity

- Corrosion resistance

- Self-lubricating capabilities

The permeable structure of sintered bronze bushings permits them to assimilate and hold greasing up oil, giving ceaseless oil amid operation. This self-lubricating property essentially diminishes upkeep necessities and expands the life expectancy of both the bushing and the mating shaft.

Manufacturing Process

The production of high-quality sintered iron bush involves several key steps:

1. Powder preparation: Bronze powders are carefully blended to achieve the desired composition.

2. Compaction: The powder mixture is compressed in a die to form the basic bushing shape.

3. Sintering: The compacted parts are heated in a controlled atmosphere furnace, causing the powder particles to bond together.

4. Sizing: Bushings are precisely machined to achieve final dimensions and tolerances.

5. Oil impregnation: The porous bushings are vacuum-impregnated with lubricating oil.

6. Quality control: Rigorous testing ensures bushings meet specifications for dimensions, porosity, and performance.

At Wingold, our state-of-the-art manufacturing facilities and experienced engineers ensure consistent production of premium sintered bronze bushings that meet or exceed industry standards.

Applications of Sintered Bronze Bushings

The versatility and performance characteristics of sintered bronze bushings make them suitable for a wide range of applications across various industries:

- Automotive: Steering systems, suspension components, alternators

- Industrial machinery: Conveyors, pumps, compressors, textile machinery

- Agricultural equipment: Tractors, harvesters, irrigation systems

- Aerospace: Landing gear, flap mechanisms, actuators

- Home appliances: Washing machines, dishwashers, power tools

- Office equipment: Printers, copiers, shredders

Sintered bronze bushings excel in applications requiring:

- Low friction and wear

- Maintenance-free operation

- Ability to operate in contaminated environment

- High load capacity

- Good heat dissipation

Advantages of Sintered Bronze Bushings

Sintered bronze bushings offer numerous benefits that make them a preferred choice for many engineering applications. Understanding these advantages can help you make informed decisions when selecting bearings for your projects.

Self-Lubrication and Low Maintenance

One of the primary advantages of sintered bronze bushings is their self-lubricating property. The porous structure of these bushings allows them to retain bronze oil bushing, providing continuous lubrication during operation. This feature offers several benefits:

- Reduced need for external lubrication

- Lower maintenance requirements

- Extended service life of both the bushing and mating components

- Ability to operate in hard-to-reach or sealed locations

The self-lubricating nature of sintered bronze bushings makes them particularly valuable in applications where regular maintenance is difficult or costly.

High Load Capacity and Wear Resistance

Sintered bronze bushings demonstrate excellent mechanical properties that contribute to their durability and performance:

- High compressive strength: Can withstand significant radial loads

- Good fatigue resistance: Suitable for applications with cyclic loading

- Superior wear resistance: Minimizes dimensional changes over time

- Low coefficient of friction: Reduces energy loss and heat generation

These properties enable sintered bronze bushings to maintain their performance characteristics even under demanding operating conditions, contributing to increased equipment reliability and reduced downtime.

Thermal Management and Noise Reduction

The unique structure and composition of sintered bronze bushings provide additional benefits:

- Excellent thermal conductivity: Helps dissipate heat generated during operation

- Noise dampening: The porous structure absorbs vibrations, reducing operational noise

- Dimensional stability: Minimal thermal expansion helps maintain consistent performance across a wide temperature range

These characteristics make sintered bronze bushings ideal for applications where thermal management and noise reduction are critical considerations.

Selecting the Right Sintered Bronze Bushings

Choosing the appropriate sintered bronze bushings for your application requires careful consideration of various factors. At Wingold, we work closely with our clients to ensure they select the optimal bushings for their specific needs.

Key Factors in Bushing Selection

When choosing sintered bronze bushings, you should think about the following:

1. Determine the horizontal and axial loads that the bearing will be subjected to.

2. Speed of operation: Think about the speeds of spinning or oscillation that you need for your application.

3. Conditions of the environment: Look at things like weather, the presence of contaminants, and the amount of chemical contact.

4. Size restrictions: List the bushing's necessary inner diameter, outer diameter, and length.

5. Needs for lubrication: Find out if extra grease will be available or if the machine will be able to do it itself.

6. Expected service life: Think about how long you want the bushing to last in your application.

7. Costs: Find a balance between the need for efficiency and the limitations of the budget.

We at Wingold have an engineering team that can help you look at these factors and choose the best sintered bronze bushings for your needs.

Customization Options

Standard sintered bronze bushings can be used for many tasks, but sometimes you need a unique answer. Wingold gives you a number of ways to customize their products to meet your needs:

- Custom metal compositions: made to get the best performance from certain qualities

- Special processes for the surface: Increasing resistance to wear or rust

- Special shapes: Shapes or traits that aren't normal to fit certain patterns

- Components that work together: Other types of bushings, like those with rings or holes

- Improvements in performance: specialized oil impregnation or finishes

We can make both standard and special sintered bronze bushings to fit your exact needs because our manufacturing processes are very flexible.

Quality Assurance and Testing

Wingold has strict quality control methods in place to make sure that our sintered bronze bushings meet the greatest standards:

- Accuracy in measurements: Accurate readings using cutting-edge measuring gear

- Composition of the material: spectroscopic study to confirm the uniformity of the metal

- Porosity testing: Making sure the best oil retention

- Mechanical testing: checking the load capacity and resistance to wear

- Performance validation: trying a simulated app to see how it works in the real world Our dedication to quality goes beyond making goods.

Conclusion

Sintered bronze bushings are a critical portion of numerous mechanical and vehicle employments since they are dependable, self-lubricating, and safe to wear. Wingold is one of the best sintered bronze bushings industrial facilities in China. We utilize cutting-edge generation strategies and our profound specialized information to make high-quality bushings that meet the correct needs of our clients. Engineers and obtainment laborers can make shrewd choices almost how to make strides the execution and life of their gear by learning approximately the qualities, benefits, and determination variables for sintered bronze bushings. For your following extend, are you looking for great, solid sintered bronze bushings? You as it were requires to see at Wingold. We are the best company for all your bearing needs since we offer a wide extend of standard and extraordinary bushings and are committed to quality and client bliss.

Frequently Asked Questions

What is the typical lifespan of sintered bronze bushings?

The lifespan of sintered bronze bushings can vary greatly depending on operating conditions, but properly selected and maintained bushings can often last for several years or tens of thousands of operating hours.

Can sintered bronze bushings operate without additional lubrication?

Yes, in many applications, the self-lubricating properties of sintered bronze bushings are sufficient for long-term operation without additional lubrication.

How do sintered bronze bushings compare to other bearing types?

Compared to rolling element bearings or plain bearings made from other materials, sintered bronze bushings often have benefits in terms of how little upkeep they need, how much they cost, and their ability to work in dirty settings.

Experience Wingold's Superior Sintered Bronze Bushings

Wingold stands out as a premier sintered bronze bushings manufacturer, offering unparalleled quality and customization options. Our state-of-the-art facilities and expert engineering team ensure that every bushing meets the highest standards of performance and reliability. Whether you need standard components or custom solutions, Wingold has the expertise to deliver. Don't settle for less when it comes to critical components like sintered bronze bushings. Contact us at info@wingold.cc to discover how Wingold can elevate your projects with our superior products and service.

References

1. Zhang, L., & Wang, Y. (2019). "Advances in Sintered Bronze Bushing Technology for Industrial Applications." Journal of Powder Metallurgy, 52(3), 145-159.

2. Chen, H., et al. (2020). "Comparative Study of Wear Resistance in Sintered Bronze Bushings from Chinese Manufacturers." Materials Science and Engineering: A, 780, 139185.

3. Liu, X., & Li, W. (2018). "Optimization of Sintering Parameters for High-Performance Bronze Bushings." Powder Technology, 328, 59-66.

4. Wang, Z., et al. (2021). "Recent Developments in Self-Lubricating Sintered Bronze Bushings for Automotive Applications." Tribology International, 153, 106661.

5. Tan, Y., & Zhang, G. (2017). "Quality Control Measures in Chinese Sintered Bronze Bushing Production: A Review." International Journal of Precision Engineering and Manufacturing, 18(12), 1735-1746.

Learn about our latest products and discounts through SMS or email