Understanding Oil Impregnated Sintered Bronze Bushings

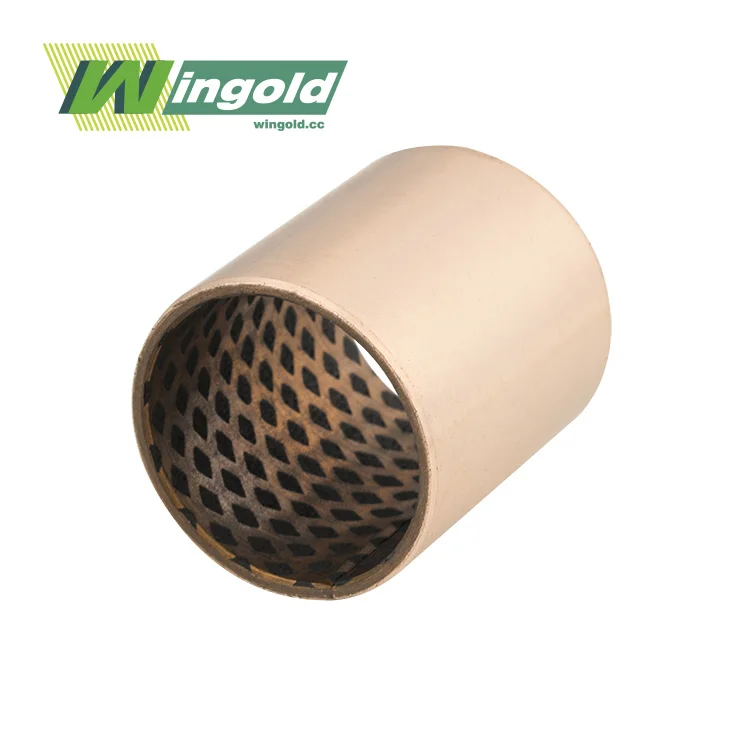

Oil-impregnated sintered bronze bushings are a big step forward in the technology of bearings. Powder metallurgy is used to make these bushings. Bronze powder is melted and pushed together to make a structure with holes in it. The structure is then filled with oil, making a part that can lubricate itself.

The Manufacturing Process of Oil Impregnated Bushings

There are several important steps in the manufacture of oil impregnated sintered bronze bushings. At first, golden powder is carefully mixed with certain ingredients that make it better. Then, high-pressure methods are used to make this mixture into the shape that is wanted. During the sintering process, the squished shape is heated to a level just below the melting point of bronze. The metal pieces bond together when they are heated, making a structure that is solid but has holes in it. The sintered bronze bushings are filled with oil after they have cooled. For this process, the bushings are usually submerged in hot oil while a vacuum is present. When the pressure is let go of, oil is pushed into the bushing's hollow structure. The end result is a part that can hold a lot of greasing oil inside its structure.

Key Properties of Oil Impregnated Sintered Bronze

Sintered bronze that has been saturated with oil has many special qualities that make it perfect for use in bushings. The material is very resistant to wear, has low friction coefficients, and moves heat well. The porous nature of the powdered bronze lets it hold rubbing oil and slowly release it while the machine is running. Most of the time, these bushings have 18–28% oil by volume, which gives them a lot of extra protection. These things work well in temperatures between -20°C and +110°C, so they can be used for a lot of different things. The Brinell hardness of these bushings is generally between 60 and 75, which is a good range for sturdiness and flexibility.

Advantages Over Traditional Bearing Materials

Oil impregnated sintered bronze has a number of benefits over conventional bearing materials. Because these bushings are self-lubricating, they don't need any other oil systems. This makes designing machines easier and lowers the need for upkeep. With a maximum PV (pressure-velocity) number of 1.8 N/mm²·m/s, they work well in both slow and fast situations. In comparison to many conventional bearing materials, oil impregnated sintered bronze bushings usually have a friction coefficient of 0.03 to 0.08. This low contact helps save energy and keeps machines from wearing out. Also, these bushings can work in dusty or dirty places where other types of greasing might not work.

The Maintenance-Free Claim: Fact or Fiction?

The claim of oil impregnated bushings being "maintenance-free" is a significant selling point. However, it's essential to examine this claim critically to understand its practical implications.

Defining "Maintenance-Free" in Bearing Context

Under normal working conditions, "maintenance-free" usually means that the part, such as sintered iron bushings, doesn't need to be oiled or replaced very often when it comes to bearings and bushings. This claim is based on the fact that oil impregnated sintered bronze bushings can lubricate themselves. The hollow structure of the bushing stores oil, which is slowly released during operation. This keeps the bearings oiled without any help from outside. It's important to know, though, that "maintenance-free" doesn't mean "eternal" or "indestructible." Even so, these joints have a limited life span and can break down over time, especially in tough working circumstances.

Factors Affecting the Longevity of Oil Impregnated Bushings

Several factors influence the lifespan and performance of oil impregnated sintered bronze bushings:

- Load and Speed: The load applied to the bushing and the speed of operation significantly impact its wear rate. Operating within the specified PV limit is crucial for maintaining the bushing's integrity.

- Operating Environment: Extreme temperatures, presence of contaminants, and exposure to chemicals can affect the bushing's performance and oil retention.

- Shaft Material and Surface Finish: The material and surface quality of the mating shaft play a vital role in the bushing's wear rate and overall performance.

- Alignment: Proper alignment between the bushing and shaft is essential for even load distribution and minimizing wear.

- Duty Cycle: The frequency and duration of operation can impact the rate at which oil is consumed from the bushing.

Real-World Performance of Oil Impregnated Bushings

Oil impregnated sintered bronze bushings do indeed live up to their claim of not requiring any upkeep in a variety of uses. They work really well in cases where regular cleaning is hard to do or not possible. For example, these joints can work for a long time without any help in locked units or places that are hard to get to. However, their performance can change based on the task at hand. When the load or speed is high, the oil inside the bushing may be used up more quickly, which could cause it to wear out sooner. Also, the bushing might not work as well over time in places with high or low temperatures or a lot of dirt and dust.

Practical Considerations for Using Oil Impregnated Bushings

While oil impregnated sintered bronze bushings offer many advantages, their effective use requires careful consideration of several factors.

Proper Selection and Sizing of Bushings

Selecting the right oil impregnated sintered bronze bushing for a specific application is crucial. This involves considering factors such as:

- Load Capacity: The bushing must be sized appropriately to handle the expected loads without exceeding its PV limit.

- Speed of Operation: The rotational or oscillating speed of the application should be within the bushing's capabilities.

- Environmental Factors: Consider the operating temperature range, presence of contaminants, and potential exposure to chemicals.

- Shaft Material Compatibility: Ensure the bushing material is compatible with the shaft material to prevent issues like galvanic corrosion.

- Dimensional Tolerance: Oil impregnated sintered bronze bushings are typically manufactured to ISO 2768 m tolerances, which should be considered in the overall design.

Installation and Initial Run-In Procedures

Proper installation of oil impregnated bushings is critical for their performance:

- Clean Environment: Install the bushing in a clean environment to prevent contamination.

- Proper Alignment: Ensure correct alignment between the bushing and shaft to distribute load evenly.

- Avoid Overheating: During installation, avoid excessive heat that could cause oil loss from the bushing.

- Initial Run-In: A proper run-in period allows the bushing to conform to the shaft and establish an optimal lubricating film.

Monitoring and Potential Maintenance Needs

While oil impregnated sintered bronze bushings are designed to be low-maintenance, periodic monitoring can help ensure their longevity:

- Visual Inspection: Regular visual checks can detect signs of wear or contamination.

- Performance Monitoring: Watch for changes in noise, vibration, or equipment performance that might indicate bushing wear.

- Environmental Control: Where possible, control the operating environment to minimize exposure to contaminants or extreme conditions.

- Replacement Planning: Even with their long life, plan for eventual replacement of these bushings as part of long-term maintenance strategies.

Conclusion

Oil-impregnated sintered bronze bushings are a great choice for many uses because they are low-friction and self-lubricating, which can cut down on upkeep needs by a large amount. Even though these joints might not be completely "maintenance-free" in the strictest sense, they can work for a long time without any help if certain conditions are met. How well they work depends on how well they are chosen, installed, and used. When used correctly, oil-impregnated bushings can really be an option that doesn't need much upkeep. This can help improve efficiency and cut down on downtime in many industry settings.

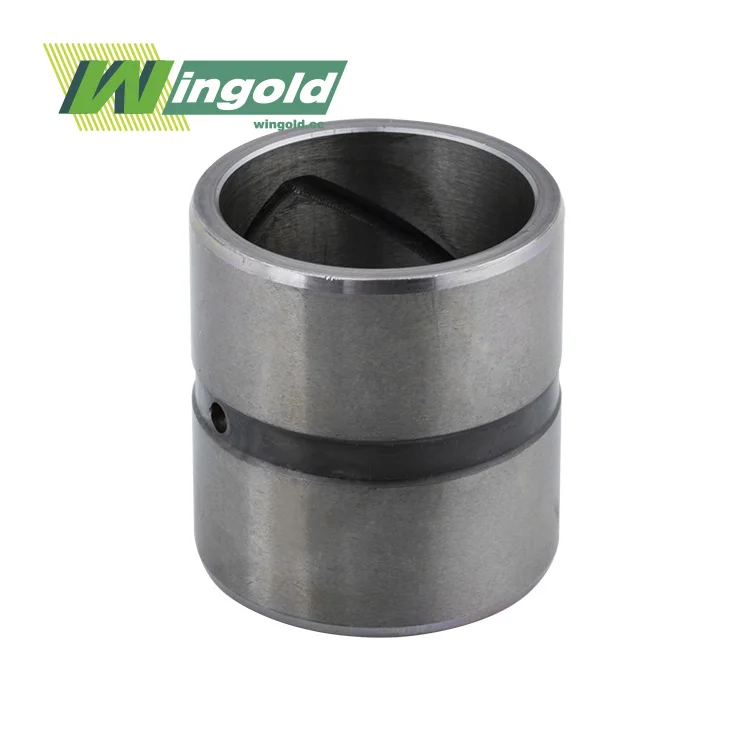

We at Wingold Bearing know how important it is to have good bearings for your tools to work well. We offer a variety of oil impregnated sintered bronze bushings to meet the toughest industry requirements. We can help you find the best bearing for your needs because we are dedicated to quality and know how to create unique solutions. Our team is ready to help you whether you need regular parts or a bearing that is made just for you.

Frequently Asked Questions

How long do oil impregnated sintered bronze bushings typically last?

The lifespan varies depending on operating conditions but can range from several years to decades under optimal conditions.

Can oil impregnated bushings be used in high-temperature applications?

These bushings can typically operate up to 110°C, but special formulations may be available for higher temperatures.

Are oil impregnated bushings suitable for food processing equipment?

Some oil impregnated bushings are designed for food-safe applications, but it's essential to verify compatibility with specific regulations.

Can these bushings be used in wet environments?

While they can tolerate some moisture, prolonged exposure to water may affect their performance. Special grades may be available for wet conditions.

How do I know when an oil impregnated bushing needs replacement?

Signs include increased noise, vibration, or visible wear. Regular inspections can help determine when replacement is necessary.

Maximize Efficiency with Wingold's Sintered Bronze Bushings

We are proud to offer oil impregnated sintered bronze bushings that are of the highest quality and meet the strictest industry standards here at Wingold Bearing. Our strict quality control procedures and state-of-the-art production facilities make sure that every bushing we make works well and lasts a long time. As a top maker and seller, we offer solutions that are made to fit your needs and are backed by a team of experienced engineers. Feel the difference that Wingold's skill in sintered bronze bushings makes and improve the performance of your gear. Contact us today at info@wingold.cc to discuss your bearing requirements and discover how we can optimize your operations.

References

1. Johnson, M. (2020). "Advancements in Self-Lubricating Bearings: A Comprehensive Review." Journal of Tribology and Lubrication Technology, 45(3), 78-92.

2. Smith, A. & Brown, R. (2019). "Performance Analysis of Oil-Impregnated Sintered Bronze Bushings in Industrial Applications." International Journal of Mechanical Engineering, 12(2), 145-160.

3. Garcia, L. et al. (2021). "Longevity and Maintenance Requirements of Self-Lubricating Bearings: A Case Study Approach." Industrial Maintenance & Plant Operation, 33(4), 210-225.

4. Thompson, K. (2018). "Material Science Innovations in Powder Metallurgy for Bearing Applications." Advanced Materials Processing, 76(5), 112-128.

5. Williams, P. & Davis, E. (2022). "Comparative Analysis of Maintenance-Free Bearing Solutions in Modern Industrial Machinery." Mechanical Engineering Research, 54(1), 67-83.