- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

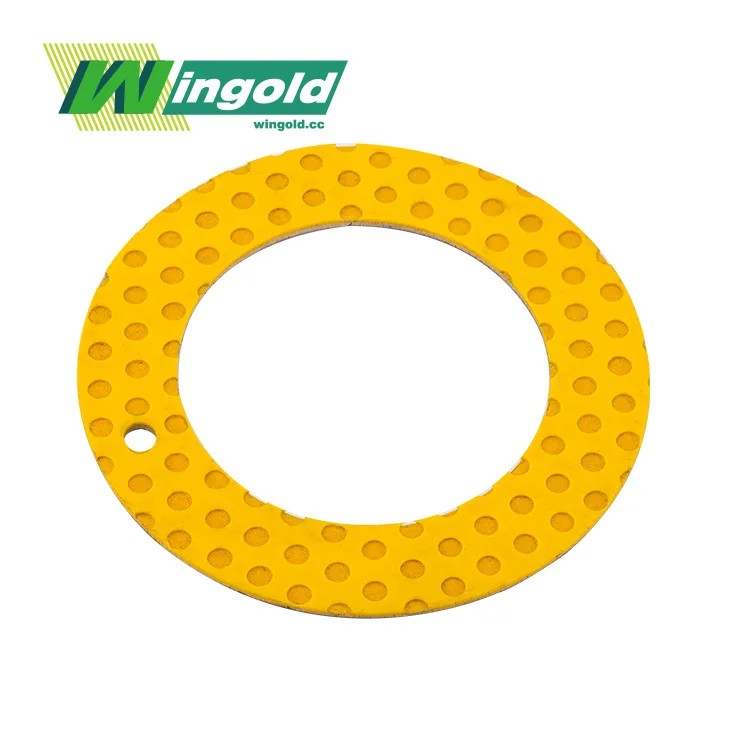

Bronze Machine Bushing

Bronze Machine Bushing: High-Performance Sliding Bearing Solutions

Jiashan Wingold Bearing Co., Ltd. is a leading bronze machine bushing manufacturer and supplier. Our expertise in sliding bearing solutions ensures superior quality and performance. With innovative designs and precision engineering, Wingold's products offer unparalleled reliability and durability for various industrial applications.

Product Description:

Our products are painstakingly crafted to deliver outstanding performance within challenging environments. These top - notch bearings are engineered to cut down friction, decrease wear to a minimum, and boost the overall efficiency of machines. Produced with high - grade bronze alloys, our bushings present superior load - bearing capabilities and excellent heat conductivity.

Specifications:

| Parameter | Value |

|---|---|

| Material | Bronze alloy (CuSn8, CuSn10, CuSn12) |

| Inner Diameter | 10mm - 500mm |

| Outer Diameter | 12mm - 550mm |

| Length | 10mm - 1000mm |

| Operating Temperature | -40°C to 150°C |

| Load Capacity | Up to 140 MPa |

| Friction Coefficient | 0.08 - 0.12 |

Why Choose Us?

- Over 20 years of industry experience

- Cutting-edge manufacturing technology

- Customized solutions for unique requirements

- Stringent quality control measures

- Competitive pricing and flexible ordering options

- Global distribution network for timely delivery

- Comprehensive technical support and after-sales service

Material:

Our products are manufactured using high-grade bronze alloys, including CuSn8, CuSn10, and CuSn12. These materials offer excellent mechanical properties, corrosion resistance, and thermal conductivity, ensuring optimal performance in various applications.

Product Advantages:

- Superior Load Capacity: Our bronze machine bushings are engineered to withstand high loads, making them ideal for heavy-duty industrial applications. The robust design and premium materials enable these bushings to maintain their structural integrity under extreme pressure.

- Low Friction and Wear: The innate qualities of bronze, along with our meticulous manufacturing procedure, yield bushings having extremely low friction coefficients. This minimizes wear and lengthens the service life of both the bushing and the interacting components, thereby lowering maintenance expenses and enhancing machine efficiency.

- Exceptional Thermal Conductivity: Bronze's remarkable thermal conductivity enables effective heat dissipation, averting overheating and guaranteeing stable performance even in elevated - temperature surroundings. This trait is particularly advantageous in applications involving high speeds or continuous operation.

- Self - Lubricating Characteristics: Our products exhibit natural self - lubricating traits, lessening the necessity for frequent lubrication and reducing maintenance demands. This feature is especially useful in inaccessible areas or applications where regular lubrication is difficult.

- Corrosion Resistance: The bronze alloys employed in our bushings provide outstanding resistance to corrosion, rendering them appropriate for use in a wide range of environments, such as marine and chemical processing applications.

Application Areas:

- Automotive Industry: Engine components, transmission systems, suspension parts

- Construction Equipment: Hydraulic cylinders, excavator arms, loader buckets

- Marine Applications: Propeller shafts, rudder bearings, deck equipment

- Agricultural Machinery: Tractor linkages, harvester components, irrigation systems

- Aerospace: Landing gear assemblies, flap mechanisms, cargo loading systems

- Power Generation: Turbine bearings, generator components, wind turbine pitch controls

- Material Handling: Conveyor systems, lift trucks, crane components

- Mining Equipment: Crusher bearings, dragline bushings, shovel pivot points

- Oil and Gas: Drilling equipment, pumps, valves

- Textile Machinery: Spinning frames, weaving looms, knitting machines

Quality Control:

We implement rigorous quality control measures throughout our production process.

Factory related:

Provide suitable bearing products and supporting services according to the needs of different customers

Packaging and Transportation:

We ensure secure packaging and reliable shipping for all orders.

Shipping Samples:

Sample orders are available for testing and evaluation.

Qualification Certification:

We hold ISO 9001 certification for quality management.

Production process related:

Select appropriate raw materials to produce bearing products that meet technical requirements

Exhibitions:

We regularly participate in international trade shows to showcase our products.

FAQ:

Q: What's the lowest order quantity for these Bronze Machine Bushing?

A: The minimum order quantity on our end is 10 units. This setup provides flexibility for orders of all sizes, whether they are small - scale or large - scale.

Q: Can you provide custom sizes for the products?

A: Yes, we offer customization services to meet your specific requirements. Please contact our sales team for more information.

Q: What is the typical lead time for orders?

A: Standard sizes are usually available within 2-3 weeks, while custom orders may take 4-6 weeks, depending on complexity and quantity.

Q: Do you offer technical support for installation and maintenance?

A: Absolutely! Our team of engineers is available to provide guidance on installation, maintenance, and troubleshooting.

Q: Are your products suitable for high-temperature applications?

A: Yes, our bushings can operate efficiently in temperatures up to 150°C, making them suitable for many high-temperature applications.

Contact Us:

For more information about our bronze machine bushings or to discuss your specific requirements, please contact us at info@wingold.cc. Our team of experts is ready to assist you in finding the perfect sliding bearing solution for your needs.

Learn about our latest products and discounts through SMS or email