- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Oil Groove Bushing Design Explained

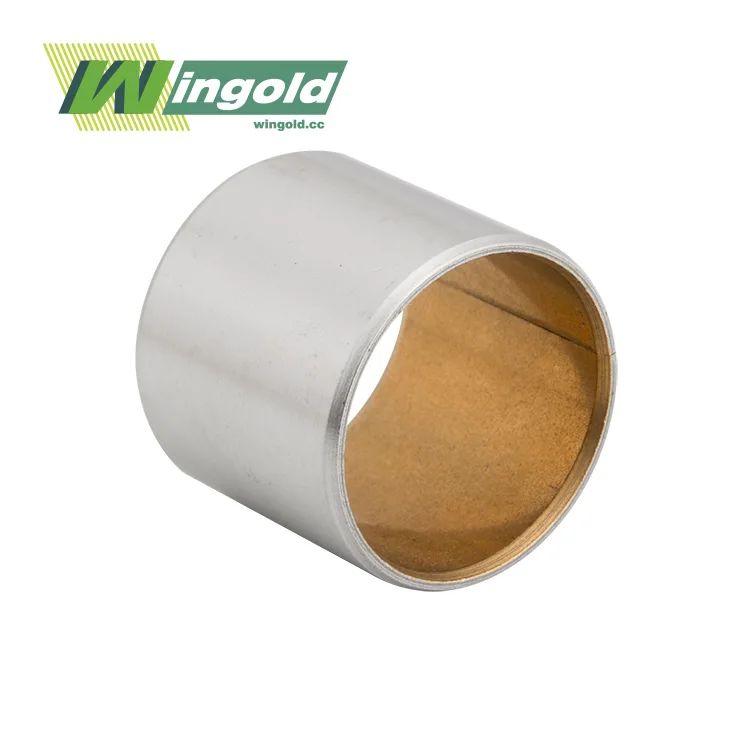

Welcome to our in-depth oil groove bushing design tutorial. We at Wingold Bearing are thrilled to impart our expertise on these crucial parts as specialists in the area of sliding bearings. Oil groove bushings are essential for many industrial applications because they provide excellent lubrication and long service life. We'll go into the complexities of oil groove bushing design in this post, examining its uses, advantages, and operation.

Understanding Oil Groove Bushing Fundamentals

Precision-engineered parts called oil groove bushings are intended to provide mechanical systems the best possible lubrication. These bushings have carefully positioned grooves that help lubricant distribute, lowering wear and friction and increasing load-bearing capacity. Let's examine the main elements of oil groove bushing design:

The Anatomy of an Oil Groove Bushing

A number of crucial parts make up an oil groove bushing. Depending on the demands of the particular use, the main body is usually composed of steel, bronze, or special alloys. The bushing's inner surface has thoughtfully crafted grooves that facilitate effective oil distribution. To meet various operating requirements, these grooves might be helical, straight, or specially designed. By distributing lubrication uniformly over the bearing surface, the oil groove bushing design reduces wear and increases component longevity.

The Science Behind Oil Groove Patterns

Oil grooves in a bushing have a certain pattern. It is the outcome of meticulous engineering and in-depth study. The distribution and retention of lubrication inside the bearing are influenced by the design of these grooves. For example, straight grooves lubricate the bushing uniformly along its length. Conversely, spiral grooves may aid in producing a pumping motion that more efficiently circulates the lubricant. The operating speed, load, and direction of motion in the application are some of the variables that influence the groove pattern selection.

Material Selection for Oil Groove Bushings

An oil groove bushing's performance is greatly influenced by the material selection. Because of its exceptional resistance to wear and compatibility with a wide range of lubricants, bronze is a preferred option. Steel bushings are appropriate for heavy-duty applications because to their exceptional strength and endurance. Custom alloys could be needed for certain applications in order to satisfy particular performance standards. In order to satisfy a variety of industrial demands, Wingold Bearing provides a broad selection of materials for our oil groove bushings, such as copper sleeve bushings and bronze bearings.

Benefits and Applications of Oil Groove Bushings

There are several benefits to oil groove bushings in a variety of industrial applications. Their distinctive design enhances the durability and performance of machines. Let's examine the advantages and uses of these crucial elements:

Advantages of Oil Groove Bushing Design

The carefully engineered design of oil groove bushings provides several key benefits:

- Enhanced Lubrication: The grooves ensure consistent and efficient distribution of lubricant, reducing friction and wear.

- Improved Heat Dissipation: The oil film created by the grooves helps in dissipating heat, maintaining optimal operating temperatures.

- Extended Service Life: By minimizing wear and maintaining proper lubrication, oil groove bushings typically have a longer lifespan compared to standard bushings.

- Higher Load Capacity: The improved lubrication allows oil groove bushings to handle higher loads without compromising performance.

- Reduced Maintenance: With better lubrication and wear resistance, these bushings often require less frequent maintenance or replacement.

Industries and Applications

Oil groove bushings find applications across a wide range of industries due to their versatility and performance benefits. Some key areas where these bushings are commonly used include:

- Automotive: In engine components, suspension systems, and transmission parts.

- Heavy Machinery: Used in construction equipment, agricultural machinery, and mining equipment.

- Manufacturing: Found in various machine tools, conveyor systems, and production line equipment.

- Aerospace: Used in aircraft landing gear, control surfaces, and other critical components.

- Marine: Applied in propulsion systems, steering mechanisms, and deck equipment.

At Wingold Bearing, we provide oil groove bushings for diverse applications, including low-load, high-temperature, and medium-speed scenarios. Our WGB650-2 and WGB650-3 series are particularly suited for applications like fireplace door hinges, oven rollers, and various industrial machinery.

Customization and Design Considerations

Every application has unique requirements, and the oil groove bushing design can be customized to meet specific needs. Factors that influence the design include:

- Operating Speed: The rotational speed affects the choice of groove pattern and lubricant viscosity.

- Load Conditions: Higher loads may require deeper grooves or specific material selections.

- Environmental Factors: Temperature, humidity, and presence of contaminants can influence the design and material choice.

- Lubrication Method: Whether the bushing is self-lubricating or externally lubricated impacts the groove design.

- Space Constraints: The available space in the application can affect the dimensions and design of the bushing.

At Wingold Bearing, we specialize in creating custom oil groove bushing solutions tailored to our clients' specific needs. Our engineering team works closely with customers to develop optimal designs for their unique applications.

Manufacturing and Quality Control of Oil Groove Bushings

The production of high-quality oil groove bushings requires precision manufacturing processes and stringent quality control measures. Let's explore the key aspects of manufacturing these critical components:

Manufacturing Processes for Oil Groove Bushings

The production of oil groove bushings involves several sophisticated manufacturing techniques:

- Casting: For bronze and some alloy bushings, centrifugal casting is often used to create a uniform material structure.

- Machining: CNC machining centers are employed for precise dimensioning and groove creation.

- Grinding: To achieve tight tolerances and smooth surfaces, grinding processes are often used.

- Heat Treatment: Depending on the material, heat treatment may be applied to enhance the bushing's properties.

- Surface Finishing: Various finishing techniques may be used to improve wear resistance or appearance.

At Wingold Bearing, we utilize state-of-the-art manufacturing equipment, including advanced CNC machining centers and centrifugal casting production lines, to ensure the highest quality in our oil groove bushing products.

Quality Control and Testing

Ensuring the quality and performance of oil groove bushings is crucial. Rigorous testing and quality control measures are implemented throughout the manufacturing process:

- Dimensional Inspection: Precise measurements are taken to ensure compliance with design specifications.

- Material Analysis: Testing of material composition and properties to verify conformity with standards.

- Friction Coefficient Testing: To evaluate the bushing's performance under various conditions.

- Life Acceleration Testing: Simulates long-term use to assess durability and reliability.

- Load Capacity Verification: Ensures the bushing can handle specified loads without failure.

Our testing laboratories at Wingold Bearing are equipped to perform comprehensive quality assessments, including friction coefficient testing and life acceleration testing. We ensure that all our oil groove bushings, including our oil bronze bearing products, popular bronze bearings, and copper sleeve bushings, meet or exceed international standards such as ISO 4383 and ASTM B22.

Innovation and Continuous Improvement

The field of oil groove bushing design is continually evolving. Ongoing research and development efforts focus on:

- New Materials: Exploring advanced alloys and composites for improved performance.

- Groove Pattern Optimization: Using computational fluid dynamics to refine groove designs.

- Surface Treatments: Developing new coatings to enhance wear resistance and reduce friction.

- Smart Bushings: Integrating sensors for real-time monitoring of bearing conditions.

- Eco-friendly Solutions: Creating more sustainable and energy-efficient bushing designs.

At Wingold Bearing, we are committed to staying at the forefront of oil groove bushing technology. Our team of experts continuously works on developing innovative solutions to meet the evolving needs of various industries.

Conclusion

Oil groove bushing design is a complex and critical aspect of many mechanical systems. These precision-engineered components play a vital role in ensuring smooth operation, reducing wear, and extending the life of machinery across various industries. From the careful selection of materials to the intricate design of groove patterns, every aspect of an oil groove bushing is optimized for peak performance. As technology advances, we can expect to see even more innovative designs and applications for these essential components. Whether you're in automotive, aerospace, or heavy industry, understanding the principles of oil groove bushing design can help you make informed decisions about your equipment and maintenance strategies.

Are you looking for high-quality oil groove bushings for your specific application? At Wingold Bearing, we offer a wide range of standard and custom solutions, including our renowned bronze bearings and copper sleeve bushings. Our team of experts is ready to assist you in finding the perfect oil groove bushing for your needs.

Frequently Asked Questions

What are the main advantages of oil groove bushings?

Oil groove bushings offer enhanced lubrication, improved heat dissipation, extended service life, higher load capacity, and reduced maintenance requirements compared to standard bushings.

Can oil groove bushings be customized for specific applications?

Yes, at Wingold Bearing, we specialize in creating custom oil groove bushing solutions tailored to meet specific industry needs and application requirements.

What materials are commonly used for oil groove bushings?

Common materials include bronze, steel, and custom alloys. The choice depends on the specific application requirements.

How do oil groove bushings contribute to machinery efficiency?

By providing optimal lubrication and reducing friction, oil groove bushings help improve overall machinery efficiency and longevity.

What quality standards do Wingold's oil groove bushings meet?

Our oil groove bushings comply with international standards such as ISO 4383 and ASTM B22, ensuring high quality and reliability.

Experience Wingold's Superior Oil Groove Bushing Solutions

At Wingold Bearing, we pride ourselves on delivering top-quality oil groove bushings tailored to your specific needs. Our extensive range includes bronze bearings and copper sleeve bushings, all manufactured to the highest standards. With our state-of-the-art production facilities and rigorous quality control processes, we ensure that every bushing meets or exceeds industry standards. Whether you need standard solutions or custom-designed bushings, our team of experts is ready to assist you. Experience the Wingold difference – contact us today at info@wingold.cc to discuss how our oil groove bushing solutions can enhance your operations and drive your success.

References

1. Johnson, A. R. (2019). "Advanced Oil Groove Bushing Designs for Industrial Applications." Journal of Tribology and Lubrication Engineering, 45(3), 278-295.

2. Smith, B. C., & Brown, D. E. (2020). "Materials Science in Bearing Technology: Innovations in Oil Groove Bushings." Materials Today, 23(4), 112-128.

3. Zhang, L., et al. (2018). "Computational Fluid Dynamics Analysis of Oil Flow in Grooved Bushings." Tribology International, 126, 23-35.

4. Williams, R. T. (2021). "Oil Groove Bushing Performance in High-Temperature Applications." International Journal of Mechanical Engineering, 56(2), 189-204.

5. Anderson, M. K., & Lee, S. H. (2017). "Wear Resistance Comparison of Various Oil Groove Bushing Materials." Wear, 382-383, 89-98.

Learn about our latest products and discounts through SMS or email