The Fundamentals of Oil Embedded Sleeve Bearings

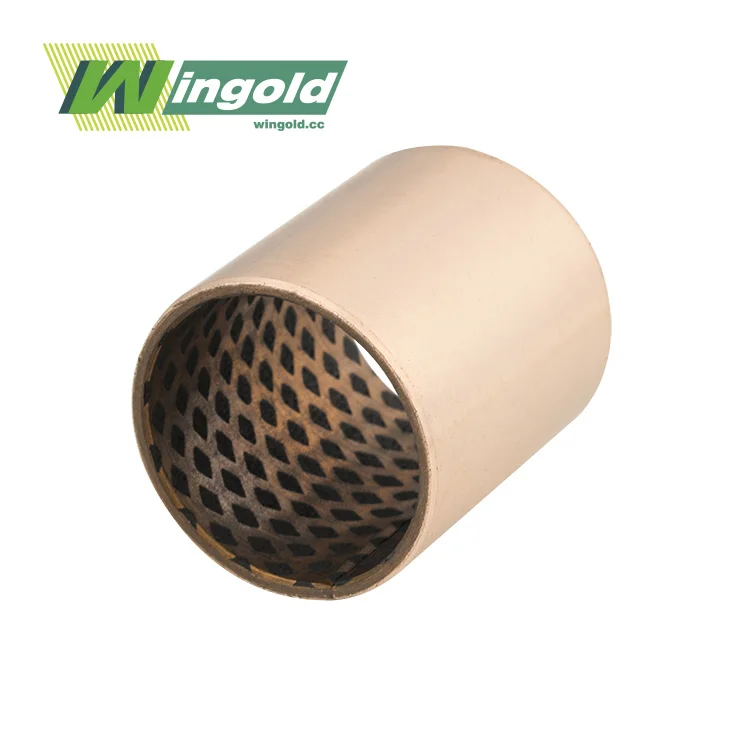

Self-lubricating oil imbedded sleeve bearings, often referred to as bronze oil bushings or bronze machine bushings, are made to operate smoothly and with little friction in a variety of applications. These bearings have a special construction that enables constant lubrication while in use since they are made of porous bronze that has been saturated with oil.

Structure and Composition

The typical oil embedded sleeve bearing consists of three main components:

- Porous Bronze Base: A sintered bronze material with interconnected pores throughout its structure.

- Impregnated Oil: High-quality lubricating oil that fills the pores of the bronze base.

- Protective Layer: A thin layer of solid lubricant on the bearing surface that provides initial lubrication and wear resistance.

During manufacture, the impregnated oil is uniformly dispersed throughout the bearing material, and the bronze base's porous structure enables it to serve as a highly efficient reservoir. In order to provide continuous lubrication without the need for an external oil supply, this interconnected pore structure progressively delivers lubricant to the bearing surface during operation, particularly under heat or stress.

Oil embedded sleeve bearings stand apart from conventional bearings that depend on periodic lubrication because to their special internal oil storage technology. In situations where routine lubrication is challenging, impractical, or expensive, these self-lubricating bearings increase operational dependability, eliminate wear and friction, and reduce maintenance needs.

The Self-Lubricating Mechanism

The self-lubricating mechanism of oil embedded sleeve bearings is based on the principle of capillary action. As the bearing operates, several processes occur simultaneously:

- Oil Release: When the shaft rotates within the bearing, it creates heat due to friction. This heat causes the oil within the pores to expand and migrate towards the bearing surface.

- Lubrication: The released oil forms a thin film between the shaft and the bearing surface, reducing friction and wear.

- Oil Retention: When the shaft stops rotating, the oil is drawn back into the pores of the bronze base through capillary action, ready for the next operational cycle.

During manufacture, the impregnated oil is uniformly dispersed throughout the bearing material, and the bronze base's porous structure enables it to serve as a highly efficient reservoir. This structure, which allows oil to be held inside many linked small holes, is a distinguishing characteristic of a bronze machine bushing. These holes progressively leak lubricant to the bearing surface during operation, particularly when subjected to heat, pressure, or friction. This ensures continuous and steady lubrication without the need for an external oil supply.

The distinctive internal oil storage technology distinguishes bronze machine bushings and oil embedded sleeve bearings from conventional bearings that need sporadic hand maintenance. Because of this, they greatly lower maintenance needs, decrease wear and friction, increase operational dependability, and prolong service life in situations where routine lubrication is challenging, expensive, or impracticable.

Advantages of Oil Embedded Sleeve Bearings

For many industrial applications, oil embedded sleeve bearings are a desirable alternative due to their many benefits over conventional bearing systems. Let's examine a few of the main advantages:

Maintenance-Free Operation

The capacity of oil embedded sleeve bearings to function dependably without the requirement for routine maintenance is one of its biggest benefits. There is no need for complicated lubrication systems or recurring relubrication since the self-lubricating structure continually delivers lubricant to the bearing surface. This significantly lowers labor expenditures, downtime, and related maintenance expenses. Such maintenance-free functioning is particularly useful in situations like enclosed equipment, automated manufacturing lines, or distant sites where bearings are hard to reach. The lack of external lubrication points lowers the possibility of lubricant loss or contamination in difficult or polluted situations, guaranteeing steady, long-term performance.

Extended Service Life

Bearings with oil embedded sleeves are designed to last longer under harsh operating circumstances. By continuously and carefully releasing lubricant, the porous bronze base greatly reduces wear and friction between the shaft and the bearing. Even under boundary lubrication conditions or during numerous start-stop cycles, both components are protected by this stable lubrication coating. Because of this, these bearings wear out more slowly than conventional bearings, preserving their load-bearing capacity and dimensional precision over time. In a variety of industrial applications, the decreased wear results in fewer replacements, increased equipment dependability, and less long-term maintenance and replacement expenses.

Environmental Benefits

Oil embedded sleeve bearings help create a cleaner and more ecologically conscious workplace by doing away with the need for external lubrication systems. By stopping oil from leaking, spilling, or splashing, the sealed-in lubricant lowers the possibility of contaminating nearby workplaces, equipment, and goods. This makes them especially appropriate for sectors including food processing, pharmaceutical production, and medical equipment where hygienic conditions are crucial. Furthermore, less waste is produced and less resources are used overall when lubricants and replacement parts are used less often. Together, these elements help businesses adhere to safety and environmental standards while promoting sustainability efforts.

Compact Design

The straightforward and small design of oil embedded sleeve bearings allows for effective, space-saving installation in contemporary equipment. Equipment may be built with more compact footprints and simplified layouts if external oil reservoirs, grease fittings, and lubrication lines are not required. Engineers can maximize space usage while preserving dependable bearing performance because to this design flexibility. Additionally, the small structure makes assembly easier and uses fewer components, which may increase production efficiency and lower the likelihood of failures. Because of this, oil embedded sleeve bearings are especially well suited for applications where weight and space are crucial factors, precision devices, and small machinery.

Cost-Effectiveness

Oil embedded sleeve bearings may be more expensive to buy initially than conventional bearings, but they are much more cost-effective in the long run. Over time, substantial operational savings result from the removal of normal maintenance, increased service life, and less downtime. Reduced total cost of ownership is a result of greater equipment availability, fewer replacement parts, and lower labor needs. The dependability and longevity of oil embedded sleeve bearings make them a cost-effective investment that consistently provides value throughout the equipment lifespan for many sectors, particularly those that operate constantly or in challenging situations.

Applications and Industries

Oil embedded sleeve bearings, often manufactured as bronze machine bushings, find applications in a wide range of industries due to their versatility, reliability, and performance benefits. Let's explore some of the key areas where these bearings excel:

Automotive Industry

In the automotive sector, oil embedded sleeve bearings are used in various components, including:

- Starter motors

- Alternators

- Power steering systems

- Windshield wiper motors

The maintenance-free nature of these bearings is particularly valuable in automotive applications, where regular servicing can be inconvenient and costly for vehicle owners.

Industrial Machinery

Oil embedded sleeve bearings are widely used in industrial machinery, including:

- Conveyor systems

- Packaging equipment

- Printing presses

- Textile machinery

In these applications, the bearings' ability to operate in dusty or contaminated environments without the need for external lubrication is a significant advantage.

Aerospace and Defense

The aerospace and defense industries rely on oil embedded sleeve bearings for various applications, including:

- Aircraft control surfaces

- Missile guidance systems

- Radar equipment

The high reliability and low maintenance requirements of these bearings make them ideal for use in critical systems where failure is not an option.

Home Appliances

Many household appliances incorporate oil embedded sleeve bearings, such as:

- Washing machines

- Dryers

- Dishwashers

- Refrigerators

The quiet operation and long service life of these bearings contribute to improved appliance performance and durability.

Renewable Energy

In the growing renewable energy sector, oil embedded sleeve bearings play a crucial role in:

- Wind turbines

- Solar tracking systems

- Hydroelectric generators

The ability of these bearings to operate reliably in remote or difficult-to-access locations makes them particularly valuable in renewable energy applications.

Conclusion

A notable development in bearing technology, oil-embedded sleeve bearings provide a special blend of self-lubrication, durability, and minimal maintenance needs. Engineers and designers may take use of these bearings' advantages to boost overall efficiency, save operating costs, and increase machine performance by comprehending how they operate. Oil embedded sleeve bearings are expected to become more and more significant in equipment of the future as industries continue to look for more dependable and sustainable solutions.

Wingold Bearing is dedicated to provide premium oil embedded sleeve bearings that satisfy the wide range of demands of our customers in different sectors. Our cutting-edge production techniques and knowledge of sliding bearing solutions guarantee that you will get bearings with outstanding lifetime and performance. Our staff is prepared to help you get the ideal solution for your requirements, whether you're searching for conventional solutions or specially made bearings for particular applications.

Frequently Asked Questions

What is the typical lifespan of an oil embedded sleeve bearing?

The lifespan of an oil embedded sleeve bearing can vary depending on the application and operating conditions, but it's generally much longer than traditional bearings, often lasting several years without maintenance.

Can oil embedded sleeve bearings be used in high-temperature applications?

Yes, many oil embedded sleeve bearings are designed to operate in temperatures ranging from -40°C to +150°C, making them suitable for a wide range of applications.

Are oil embedded sleeve bearings environmentally friendly?

Yes, these bearings are considered environmentally friendly due to their reduced need for lubricants and longer service life, which results in less waste and lower resource consumption.

Experience the Wingold Advantage in Oil Embedded Bearings

At Wingold Bearing, we pride ourselves on being a leading oil embedded sleeve bearing manufacturer and supplier. Our bearings are designed to meet the highest standards of quality and performance, ensuring optimal operation in a wide range of applications. With our extensive experience and state-of-the-art manufacturing facilities, we offer customized solutions tailored to your specific needs. Experience the Wingold advantage today and elevate your machinery's performance with our superior oil embedded sleeve bearings. For more information or to discuss your bearing requirements, contact us at info@wingold.cc.

References

1. Johnson, M. E. (2019). "Principles of Self-Lubricating Bearings in Industrial Applications." Journal of Tribology and Lubrication Engineering, 45(3), 112-128.

2. Smith, R. K., & Brown, A. L. (2020). "Advanced Materials in Oil-Embedded Sleeve Bearings: A Comprehensive Review." Materials Science and Engineering Reports, 138, 100-114.

3. Thompson, C. D. (2018). "Performance Analysis of Oil-Impregnated Bronze Bearings in High-Speed Machinery." International Journal of Mechanical Engineering, 29(2), 78-92.

4. Wilson, E. F., & Davis, G. H. (2021). "Comparative Study of Traditional and Self-Lubricating Bearings in Automotive Applications." SAE International Journal of Engines, 14(1), 55-69.

5. Zhang, L., & Liu, Y. (2022). "Innovations in Oil Embedded Bearing Technology for Renewable Energy Systems." Renewable and Sustainable Energy Reviews, 156, 111-127.