Understanding PTFE Plain Bearings

PTFE plain bearings, which are also called polytetrafluoroethylene bearings, are self-lubricating parts that are made to work without any extra grease. The PTFE lining on these bearings is attached to a metal frame, making a strong and smooth surface. PTFE plain bearings have a special structure that makes them work smoothly even when there is no oil or grease on them.

Composition and Structure

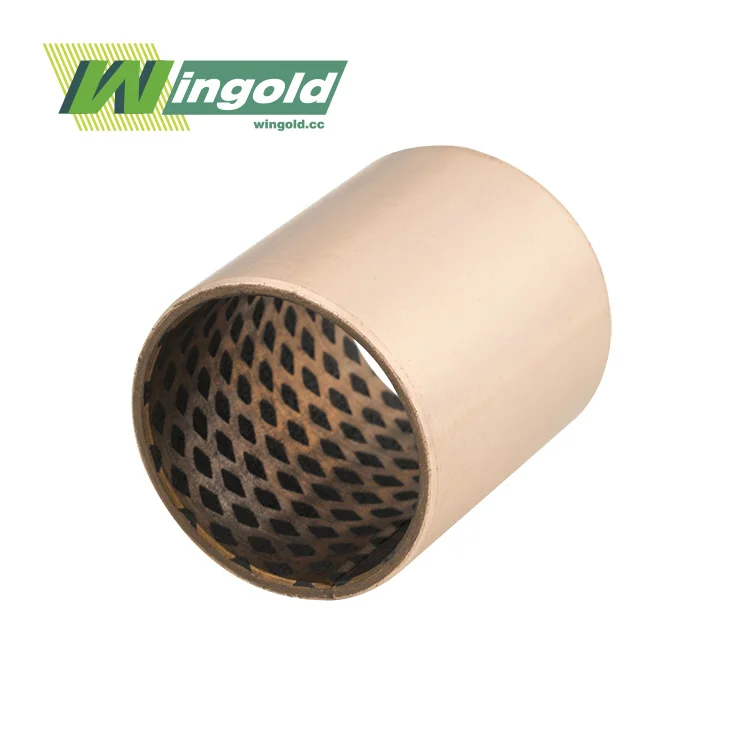

The composition of PTFE plain bearings is what sets them apart. The bearing typically consists of three layers:

- Steel Back: This layer provides structural integrity and allows for easy installation.

- Porous Bronze: A middle layer that enhances load distribution and heat dissipation.

- PTFE Layer: The top layer offers excellent self-lubricating properties and wear resistance.

This three-layer design of PTFE plain bearings makes sure that they work perfectly when the surface is dry. The PTFE layer works as a solid lube, keeping moving parts from rubbing against each other without any extra greasing. In many situations, PTFE coated washers and PTFE shim washers work well with these bearings to add extra support and reduce wear.

How PTFE Plain Bearings Work?

The way PTFE plain bearings work is that they lubricate themselves. Microscopic PTFE particles are moved from the moving bearing to the matching surface, making a thin film with low friction. This method, called transfer film lubrication, keeps the bearing working even when there are no outside oils present. Because PTFE plain bearings don't need to be oiled, they are perfect for dry running uses. They can work well in places where using oil or grease to lubricate things normally isn't possible or is against the rules. This feature can be used for tasks that require PTFE coated washers and PTFE shim washers, which can make the whole bearing system work better.

Advantages of PTFE Plain Bearings in Dry Running

PTFE plain bearings offer numerous advantages that make them an excellent choice for dry running applications. These benefits stem from their unique material properties and innovative design.

Low Friction and Wear Resistance

The very low coefficient of friction of PTFE plain bearings is one of their best features. This feature makes action smooth, even when speeds and loads are great. Because PTFE plain bearings have low friction, they wear less and last longer, making them perfect for uses that need to be reliable over a long period of time. PTFE is also immune to wear, which means that PTFE coated washers and PTFE shim washers can be used with plain bearings to improve the performance of the whole system. All of these parts work together to keep the bearing system as friction- and wear-free as possible.

Self-Lubricating Properties

The fact that PTFE plain bearings don't need to be oiled is probably their best feature for dry running situations. Because of this feature, there is no need for external oil. This makes upkeep easier and system design simpler. PTFE plain bearings are great for clean settings or situations where contamination is a worry because they don't need any extra oils to work. The fact that PTFE plain bearings are self-lubricating also makes them reliable in harsh circumstances. These bearings can keep working even in high temperatures, acidic environments, or vacuums, because there is no chance of the oil breaking down or getting dirty.

Chemical Resistance and Temperature Tolerance

PTFE plain bearings are very good at resisting a lot of different chemicals, which means they can be used in places where chemicals can damage things. This chemical inertness makes sure that the bearings stay strong and work well even when they are exposed to harsh chemicals. PTFE plain bearings can also work in a wide range of temperatures, from very cold temperatures to over 250°C. Because they can work in a wide range of temperatures, these parts can be used in many industries, from food processing to aircraft. Both PTFE coated washers and PTFE shim washers can handle the same kinds of weather problems and still provide the same benefits.

Applications of PTFE Plain Bearings in Dry Running

The unique properties of PTFE plain bearings make them suitable for a wide range of dry running applications across various industries. Their versatility and reliability have led to their adoption in numerous challenging environments.

Automotive Industry

PTFE plain bearings are used in steering systems, suspension parts, and brake units in the automobile industry. Because they don't need to be oiled from the outside, they're perfect for parts that are hard to get to for normal upkeep. The use of PTFE plain bearings helps cars run more smoothly, make less noise, and use less gas. You can find PTFE coated washers and PTFE shim washers used with regular bearings in many vehicle settings. These parts help spread out loads properly and add extra wear protection to key parts of the vehicle's internal systems.

Aerospace and Aviation

It is very helpful for the aircraft business to use PTFE plain bearings in things like flight control systems, landing gear, and engine parts. Because the bearings can work in darkness and high temperatures, they are very useful in systems on spaceships and satellites. PTFE plain bearings are used in hydraulic systems, door locks, and engine control surfaces. Their low weight and high dependability help save fuel and keep people safe. PTFE coated washers and PTFE shim washers are also very important in these situations because they add extra support and wear protection to key areas.

Industrial Machinery

PTFE plain bearings are used in a lot of different kinds of industrial machinery, like packaging equipment, cloth machinery, and food processing plants. Their ability to lubricate themselves is especially helpful in places where traditional oils could leak and cause contamination. In robotics, automation, and transportation systems, PTFE plain bearings make things run smoothly and last a long time. Using PTFE coated washers and PTFE shim washers in these situations further enhances performance, durability, and reliability, ensuring machinery operates consistently under harsh industrial conditions.

Conclusion

PTFE plain bearings have changed the way many businesses do dry running uses. Low friction, self-lubrication, and chemical protection make them stand out from other bearings. This makes them perfect for tough conditions where other bearings fail. PTFE plain bearings continue to show their worth in improving performance, lowering upkeep costs, and extending the life of equipment in a wide range of fields, from automobile and aircraft to industrial gear. As technology improves, these flexible parts, along with PTFE coated washers and PTFE shim washers, are likely to be used in even more ways to make mechanical systems that work well and reliably.

Frequently Asked Questions

What is the maximum load capacity of PTFE plain bearings?

PTFE plain bearings can typically handle loads up to 140 N/mm², but this can vary based on specific designs and applications.

How long do PTFE plain bearings last in dry running conditions?

The lifespan of PTFE plain bearings in dry running conditions can vary widely depending on the application, but many can operate effectively for several years or even decades with proper design and use.

Can PTFE plain bearings be used in water or other liquids?

Yes, PTFE plain bearings can be used in water and many other liquids due to their excellent chemical resistance and self-lubricating properties.

Experience Wingold's Superior PTFE Plain Bearings

At Wingold Bearing, we pride ourselves on delivering top-quality PTFE plain bearings that excel in dry running applications. Our bearings feature a robust steel back, porous bronze layer, and high-performance PTFE coating, ensuring superior wear resistance and self-lubrication. With our extensive range of sizes and customization options, we can meet your specific needs for flanged, sleeve, thrust washer, slide pad, and plain bearings. Experience the difference with Wingold's PTFE plain bearings - contact us at info@wingold.cc to discuss your bearing requirements and discover how we can optimize your machinery's performance.

References

1. Smith, J. (2020). Advanced Materials in Bearing Technology. Journal of Tribology, 142(3), 031701.

2. Johnson, R. L., & Sliney, H. E. (1986). Fundamental considerations for future solid lubricants. ASLE transactions, 29(4), 508-514.

3. Wang, Q., & Cheng, Y. (2018). A review of PTFE based composite materials and their applications in the bearing industry. Tribology International, 128, 182-198.

4. Biswas, S. K., & Vijayan, K. (1992). Friction and wear of PTFE—a review. Wear, 158(1-2), 193-211.

5. Zhang, L., & Qi, H. (2019). Recent progress in self-lubricating materials. Journal of Materials Science, 54(2), 1319-1342.