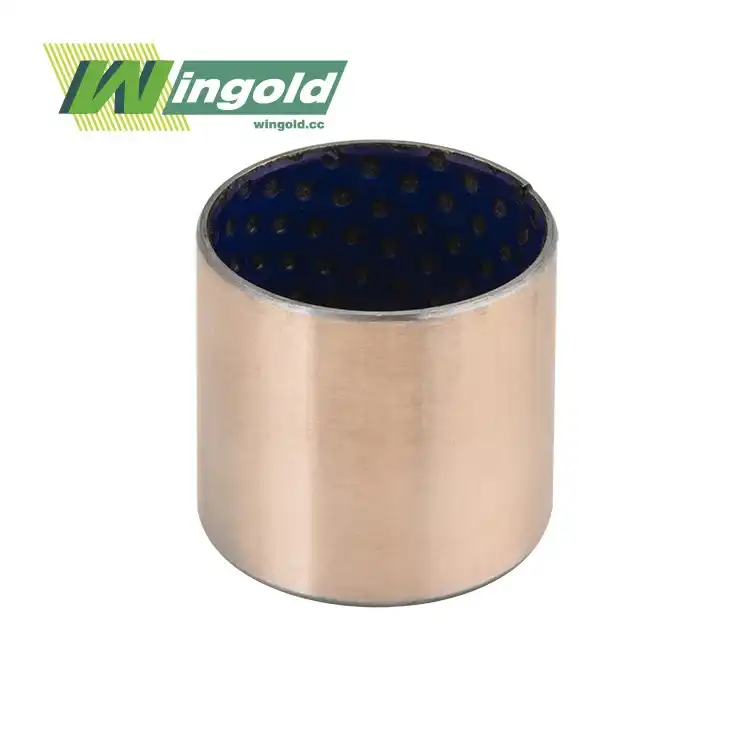

Understanding Polymer Sleeve Bearings: Composition and Properties

Material Composition

Polymer sleeve bearings are crafted from high-performance polymer blends, often incorporating materials such as polytetrafluoroethylene (PTFE), polyoxymethylene (POM), and other engineered plastics. These advanced materials are carefully selected for their exceptional mechanical properties and tribological characteristics. The unique composition of polymer bearings allows for a self-lubricating structure, eliminating the need for external lubrication in many applications.

Key Properties

The properties of polymer sleeve bearings make them ideal for a wide range of applications. They boast impressive load-bearing capacities, with some designs capable of withstanding pressures up to 140 MPa. The friction coefficient of these bearings typically ranges from 0.03 to 0.25, depending on operating conditions. This low friction contributes to reduced wear and extended component life.

Polymer bearings also exhibit remarkable temperature resistance, functioning effectively in environments ranging from -40°C to +150°C. This wide temperature range makes them suitable for diverse applications, from cryogenic equipment to high-temperature industrial processes. Additionally, their corrosion resistance and chemical inertness allow them to perform reliably in harsh environments where traditional metal bearings might fail.

Applications of Polymer Sleeve Bearings Across Industries

Automotive and Transportation

In the automotive sector, polymer sleeve bearings play a vital role in various systems, including steering mechanisms, suspension components, and pedal assemblies. Their lightweight design significantly contributes to reducing overall vehicle mass, enhancing both fuel efficiency and environmental sustainability. Additionally, the self-lubricating nature of polymer bearings minimizes friction and eliminates the need for regular greasing, thereby reducing maintenance costs and downtime. These properties improve the durability, noise reduction, and reliability of automotive systems under demanding operating conditions.

Industrial Machinery

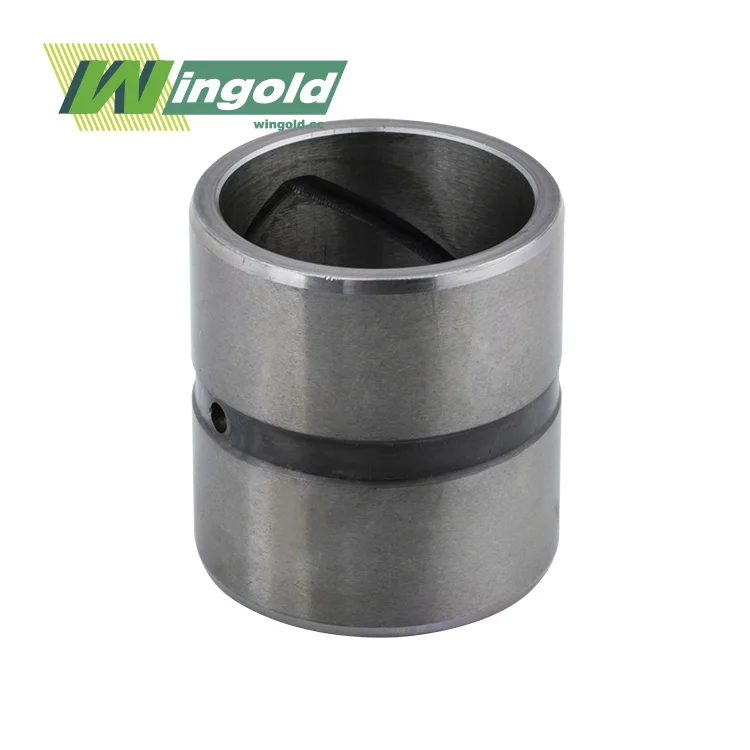

Polymer bearings are becoming increasingly popular in industrial machinery such as conveyors, packaging lines, and material handling systems. POM bush, made from durable polyoxymethylene, are a prime example of these polymer components, offering the ability to operate efficiently without external lubrication. This makes them ideal for clean or contamination-sensitive environments, including food processing and pharmaceutical production. Moreover, their resistance to wear, chemicals, and moisture ensures consistent performance even in high-load or high-speed applications. This not only extends service life but also simplifies maintenance, contributing to greater operational efficiency and reduced overall costs.

Aerospace and Defense

The aerospace and defense sectors rely on polymer sleeve bearings for their combination of lightweight construction, strength, and exceptional temperature resistance. These bearings are employed in flight control surfaces, landing gear systems, and interior cabin mechanisms. Their resistance to corrosion and chemicals ensures long-term reliability in extreme conditions such as high-altitude or marine environments. Additionally, polymer bearings help reduce vibration and noise levels while supporting precise mechanical performance, making them indispensable in mission-critical aerospace and defense applications.

Medical and Healthcare Equipment

In medical and healthcare equipment, polymer bearings are favored for their superior chemical resistance, biocompatibility, and ability to operate without external lubricants. These attributes make them suitable for use in hospital beds, diagnostic imaging devices, and surgical instruments, where hygiene and safety are critical. Their smooth, low-friction operation supports precision movements while minimizing contamination risks. Furthermore, polymer bearings provide long-lasting, maintenance-free performance, enhancing the overall reliability and efficiency of modern medical technology used in healthcare facilities.

Benefits of Implementing Polymer Sleeve Bearings

Enhanced Performance and Longevity

Polymer sleeve bearings offer superior performance compared to traditional metal bearings in many applications. Their low friction coefficients result in smoother operation and reduced energy consumption. The self-lubricating nature of these bearings eliminates the need for regular maintenance, leading to increased uptime and reduced operational costs.

Environmental and Cost Advantages

The elimination of external lubricants not only simplifies maintenance but also contributes to a cleaner environment by reducing the risk of lubricant leakage and contamination. Additionally, the lightweight nature of polymer bearings can lead to overall weight reductions in machinery, potentially improving energy efficiency and reducing fuel consumption in transportation applications.

Design Flexibility and Customization

Polymer sleeve bearings offer engineers greater design flexibility compared to traditional metal bearings. Self lubricating bushings, a type of polymer bearing, can be easily molded or machined into complex shapes, allowing for more compact and efficient designs. This adaptability enables the creation of custom solutions for specific applications, optimizing performance and seamless integration within existing systems while reducing the need for external lubrication and maintenance.

Noise Reduction and Vibration Dampening

The unique material properties of polymer bearings contribute to quieter operation and improved vibration dampening. This characteristic is particularly valuable in applications where noise reduction is crucial, such as in office equipment, household appliances, and automotive interiors.

Conclusion

Polymer sleeve bearings represent a significant advancement in bearing technology, offering a compelling combination of performance, durability, and cost-effectiveness across a wide range of industries. Their unique properties, including self-lubrication, low friction, and corrosion resistance, make them an attractive alternative to traditional metal bearings in many applications. As industries continue to seek ways to improve efficiency, reduce maintenance costs, and enhance environmental sustainability, the adoption of polymer sleeve bearings is likely to increase.

For those looking to explore the benefits of polymer sleeve bearings for their specific applications, it's crucial to partner with a reputable polymer sleeve bearings supplier or manufacturer. Wingold Bearing, with its extensive experience in sliding bearing solutions, offers a wide range of polymer sleeve bearing products tailored to meet diverse industry needs. To learn more about how Wingold's polymer sleeve bearings can benefit your operations or to discuss custom solutions, please contact us at info@wingold.cc.

Frequently Asked Questions

What are the main advantages of polymer sleeve bearings over traditional metal bearings?

Polymer sleeve bearings offer self-lubrication, lower friction, corrosion resistance, and reduced maintenance requirements compared to metal bearings.

In what temperature range can polymer sleeve bearings operate?

Typically, polymer sleeve bearings can function effectively in temperatures ranging from -40°C to +150°C, depending on the specific polymer blend used.

Are polymer sleeve bearings suitable for high-load applications?

Yes, many polymer bearing designs can withstand high loads, with some capable of handling pressures up to 140 MPa.

How do polymer sleeve bearings contribute to environmental sustainability?

By eliminating the need for external lubrication, polymer bearings reduce the risk of lubricant leakage and environmental contamination.

References

1. Smith, J. (2022). "Advanced Polymer Materials in Modern Bearing Design." Journal of Tribology and Surface Engineering, 15(3), 245-260.

2. Johnson, A., & Brown, R. (2021). "Applications of Self-Lubricating Bearings in Industrial Machinery." International Journal of Mechanical Engineering, 8(2), 112-128.

3. Lee, S., et al. (2023). "Performance Analysis of Polymer Sleeve Bearings in Automotive Applications." SAE Technical Paper Series, 2023-01-0534.

4. Garcia, M. (2022). "Environmental Benefits of Lubricant-Free Bearing Systems." Green Technology and Environmental Science Review, 7(4), 301-315.

5. Thompson, K., & Wilson, D. (2021). "Comparative Study of Polymer and Metal Bearings in Aerospace Applications." Aerospace Engineering and Technology, 12(1), 78-92.