- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

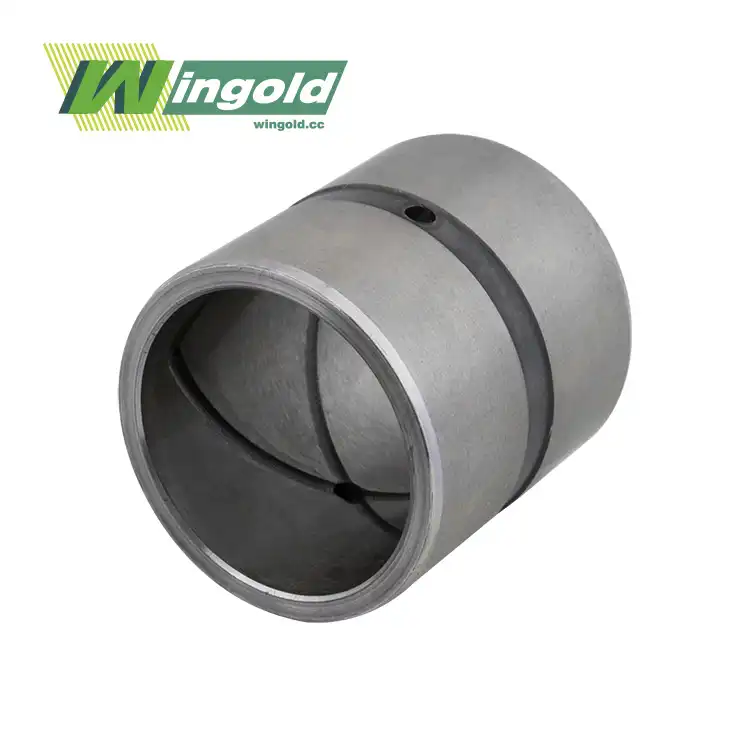

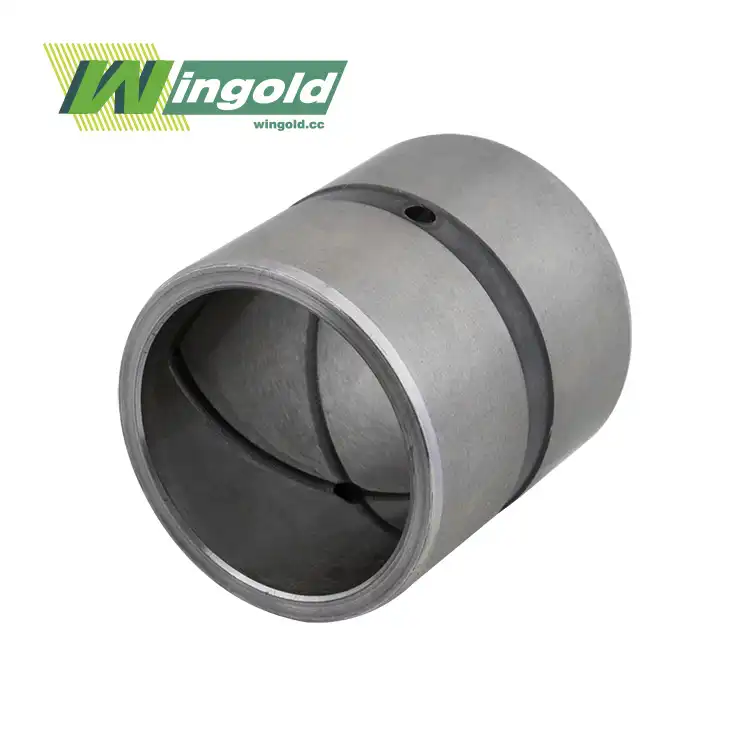

Custom Steel Bushings

Custom Steel Bushings: Precision-Engineered Solutions for Your Industry

Welcome to Jiashan Wingold Bearing Co., Ltd., your trusted manufacturer and supplier of high-quality custom steel bushings. With our state-of-the-art manufacturing capabilities and commitment to excellence, we deliver tailored solutions that meet the unique needs of diverse industries. Our products are designed to provide superior performance, longevity, and reliability in even the most demanding applications.

Product Description

Our products are meticulously engineered components fashioned to minimize friction, bear loads, and enable seamless rotation within diverse mechanical setups. Constructed from top - tier steel materials, these bushings boast extraordinary durability and wear resistance, rendering them suitable for numerous industrial uses. Jiashan Wingold Bearing Co., Ltd. acknowledges that a universal approach won't work for every situation. Hence, we focus on producing customized products to meet your particular needs. Be it bushings for the automotive, aerospace, heavy equipment sectors, or any other industry, our expert team stands by to design and fabricate the optimal solution just for you.

Specifications

| Feature | Description |

|---|---|

| Material | High-grade steel (customizable) |

| Size Range | 5mm to 500mm (inner diameter) |

| Tolerance | ±0.01mm (tighter tolerances available) |

| Surface Finish | Ra 0.2-3.2 μm (customizable) |

| Load Capacity | Up to 500 kN (depending on size and design) |

| Operating Temperature | -40°C to 200°C (extended range available) |

| Lubrication | Self-lubricating options available |

Why Choose Us?

- Over 20 years of industry experience

- Cutting-edge manufacturing technology

- Rigorous quality control processes

- Customization capabilities to meet unique specifications

- Quick turnaround times and reliable delivery

- Competitive pricing without compromising on quality

- Comprehensive technical support and after-sales service

- Commitment to continuous innovation and improvement

Material

Our custom steel bushings are manufactured using premium-grade steel alloys, carefully selected to meet the specific requirements of your application. We offer a range of materials, including:

- Carbon steel

- Alloy steel

- Stainless steel

- Tool steel

- Bearing steel

Our material selection process ensures optimal performance, durability, and corrosion resistance for your products.

Product Advantages

- Precision Engineering: Our products are manufactured to exacting tolerances, ensuring a perfect fit and optimal performance in your application. This precision reduces wear, minimizes downtime, and extends the lifespan of your equipment.

- Customization Flexibility: We offer unparalleled customization options, allowing you to specify dimensions, materials, surface treatments, and performance characteristics. This flexibility ensures that you receive bushings perfectly suited to your unique requirements.

- Superior Load Capacity: Our steel bushings are designed to handle high loads and stresses, making them ideal for demanding industrial applications. The robust construction and carefully selected materials contribute to exceptional load-bearing capabilities.

- Enhanced Wear Resistance: Through advanced surface treatments and material selection, our products offer superior wear resistance, reducing the need for frequent replacements and minimizing maintenance costs.

- Excellent Thermal Stability: Our bushings maintain their performance across a wide temperature range, ensuring reliability in diverse operating conditions.

Application Areas

- Automotive Industry: Engine components, suspension systems, steering mechanisms

- Aerospace: Landing gear, control surfaces, hydraulic systems

- Heavy Machinery: Construction equipment, agricultural machinery, mining equipment

- Marine Industry: Propeller shafts, rudder systems, winches

- Energy Sector: Wind turbines, oil and gas equipment, power generation systems

- Material Handling: Conveyor systems, lift trucks, cranes

- Industrial Manufacturing: Robotics, assembly lines, packaging equipment

- Medical Equipment: Diagnostic machines, surgical tools, rehabilitation devices

Quality Control:

We implement rigorous quality control measures throughout our production process.

Factory related:

Provide suitable bearing products and supporting services according to the needs of different customers

Packaging and Transportation:

We ensure secure packaging and reliable shipping for all orders.

Shipping Samples:

Sample orders are available for testing and evaluation.

Qualification Certification:

We hold ISO 9001 certification for quality management.

Production process related:

Select appropriate raw materials to produce bearing products that meet technical requirements

Exhibitions:

We regularly participate in international trade shows to showcase our products.

FAQ

- What is the minimum order quantity for the Custom Steel Bushings?

We can accommodate orders of various sizes, from small prototyping runs to large-scale production. Please contact us for specific details. - How long does it take to produce products?

Lead times vary depending on the complexity and volume of your order. Typically, we can deliver within 2-4 weeks for standard customizations. - Can you provide technical assistance in selecting the right bushing for my application?

Absolutely! Our engineering team is available to help you choose the optimal bushing design and material for your specific needs. - Do you offer any warranty on your products?

Yes, we stand behind the quality of our products. Please contact us for detailed warranty information. - Can you manufacture steel bushings with special coatings or surface treatments?

Certainly! We offer various surface treatments and coatings to enhance performance and durability.

Contact Us

Ready to elevate your mechanical systems with our custom steel bushings? Contact us today at info@wingold.cc to discuss your specific requirements and receive a personalized quote. Let Jiashan Wingold Bearing Co., Ltd. be your partner in precision engineering solutions!

Learn about our latest products and discounts through SMS or email