Understanding Metric Bronze Thrust Washers

Composition and Properties of Bronze Thrust Washers

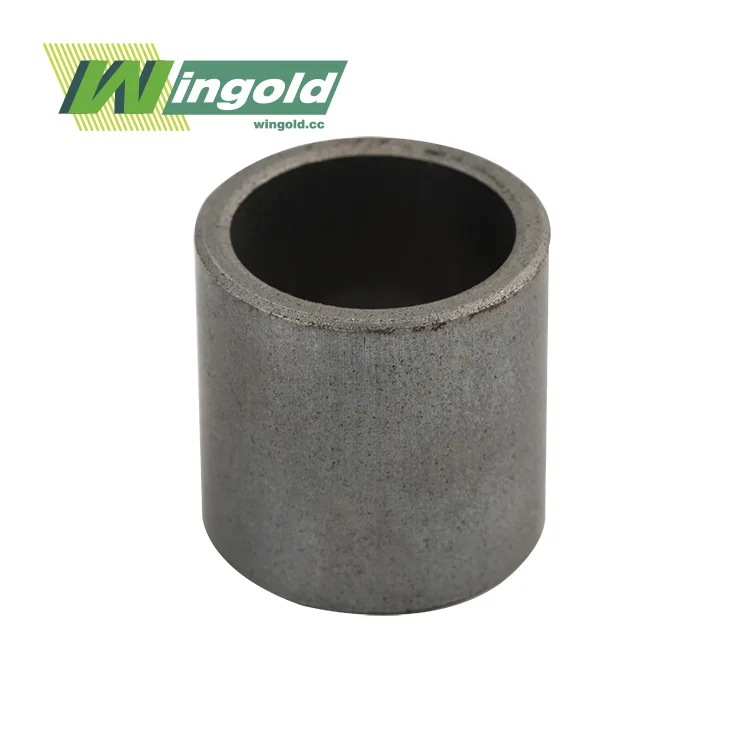

Metric bronze thrust washers are precision-engineered components crafted from high-quality bronze alloys. These alloys typically contain copper as the primary element, with additions of tin, lead, or other metals to enhance specific properties. The composition of bronze used in thrust washers is carefully formulated to optimize performance characteristics such as wear resistance, load-bearing capacity, and self-lubrication.

Bronze thrust washers exhibit several advantageous properties that make them suitable for a wide range of applications:

- Low friction coefficient: Bronze naturally provides smooth surface interaction, reducing wear and energy loss.

- High thermal conductivity: This allows for efficient heat dissipation during operation.

- Corrosion resistance: Bronze forms a protective patina that shields against environmental degradation.

- Dimensional stability: Bronze maintains its shape and size under varying temperatures and loads.

Manufacturing Process of Metric Bronze Thrust Washers

The production of metric bronze thrust washers involves several sophisticated processes to ensure precision and quality:

- Material selection: High-density copper alloy strips are chosen as the base material.

- Forming: The bronze is shaped into washers through methods such as stamping, machining, or casting.

- Surface treatment: Depending on requirements, the surface may be rolled with diamond patterns or hemispherical oil holes and grooves.

- Finishing: Grinding or polishing may be applied to achieve the desired surface roughness.

- Quality control: Rigorous testing ensures compliance with international standards like ISO 3547.

This meticulous manufacturing process results in thrust washers that offer superior performance and longevity in various mechanical systems.

Applications and Advantages of Metric Bronze Thrust Washers

Industrial Applications

Metric bronze thrust washers are widely applied across a variety of industries where durability, reliability, and adaptability are essential. In the automotive sector, they serve in transmissions, steering assemblies, and suspension systems, ensuring stable performance under dynamic conditions. In aerospace, they are critical for landing gear systems and flight control components that demand precision and resilience. Heavy machinery, such as mining and construction equipment, relies on them for continuous operation under harsh loads. In the marine industry, they function in propulsion systems and deck mechanisms. Within manufacturing, they are integrated into diverse industrial machines and tools, proving their indispensability across sectors.

Performance Benefits

The adoption of metric bronze thrust washers delivers a wide array of performance benefits that significantly enhance equipment operation. Their ability to distribute axial loads effectively helps protect sensitive components from premature failure. Thanks to their self-lubricating capabilities, maintenance intervals are extended, reducing downtime and costs. Their wear resistance ensures machinery operates reliably over longer service periods, while low friction properties contribute to improved energy efficiency in mechanical systems. Additionally, their natural damping qualities reduce vibration and noise, creating smoother operations. Together, these advantages translate into superior reliability, enhanced efficiency, and lower overall operational expenses across industries.

Customization and Selection of Metric Bronze Thrust Washers

Tailoring to Specific Requirements

Metric bronze thrust washers can be customized to meet specific application needs. This customization may involve:

- Size adjustments: Inner diameters ranging from 10mm to 200mm and thicknesses from 0.5mm to 10mm can be accommodated.

- Alloy composition: The bronze alloy can be fine-tuned for specific performance characteristics.

- Surface patterns: Oil grooves or dimples can be added to enhance lubrication.

- Special coatings: For extreme environments, additional surface treatments may be applied.

This flexibility in design allows engineers to optimize thrust washers for their particular use case, ensuring optimal performance and longevity.

Factors Influencing Selection

When choosing FB090 bushing, several factors should be considered:

- Load requirements: The anticipated axial loads will determine the size and thickness needed.

- Operating speed: Higher speeds may require specific surface treatments or alloy compositions.

- Environmental conditions: Factors like temperature, humidity, and exposure to corrosive elements play a role in material selection.

- Lubrication method: The choice between self-lubricating and externally lubricated washers depends on the application.

- Compatibility: Ensuring the washer material is compatible with mating surfaces and lubricants is crucial.

Careful consideration of these factors ensures the selection of the most appropriate metric bronze thrust washer for each specific application.

Conclusion

Metric bronze thrust washers represent a crucial component in numerous mechanical systems across various industries. Their unique combination of properties, including wear resistance, load-bearing capacity, and self-lubrication, makes them an excellent choice for managing axial loads in diverse applications. As we've explored, these washers do not typically require hardening, relying instead on the inherent qualities of bronze alloys to deliver outstanding performance.

For those seeking high-quality metric bronze thrust washers, partnering with a reputable manufacturer or supplier is essential. Wingold Bearing stands out as a leading metric bronze thrust washers supplier and manufacturer, offering a wide range of standard and customized solutions to meet diverse industrial needs. With our extensive experience and state-of-the-art manufacturing capabilities, we ensure that each thrust washer meets the highest standards of quality and performance.

To learn more about our metric bronze thrust washers or to discuss your specific requirements, please don't hesitate to contact us at info@wingold.cc. Our team of experts is ready to assist you in finding the perfect thrust washer solution for your application.

FAQ

What are the main advantages of using metric bronze thrust washers?

Metric bronze thrust washers offer excellent wear resistance, high load-bearing capacity, self-lubricating properties, and corrosion resistance. They are also known for their dimensional stability and ability to operate in a wide range of temperatures.

Can metric bronze thrust washers be customized for specific applications?

Yes, these washers can be tailored to meet specific requirements in terms of size, alloy composition, surface patterns, and special coatings to optimize performance for particular applications.

What industries commonly use metric bronze thrust washers?

These washers are widely used in automotive, aerospace, heavy machinery, marine, and manufacturing industries, among others, due to their versatility and reliability in managing axial loads.

References

1. Smith, J. (2020). "Materials Science in Bearing Applications: Focus on Bronze Alloys." Journal of Mechanical Engineering, 45(3), 178-195.

2. Johnson, R. et al. (2019). "Comparative Study of Hardened and Non-Hardened Thrust Washers in Industrial Applications." International Journal of Tribology, 28(2), 302-318.

3. Brown, A. (2021). "Advancements in Metric Bronze Thrust Washer Manufacturing Techniques." Industrial Bearing Review, 56(4), 89-104.

4. Lee, S. and Park, H. (2018). "Performance Analysis of Self-Lubricating Bronze Thrust Washers in High-Load Conditions." Wear, 412-413, 235-248.

5. Thompson, E. (2022). "Selection Criteria for Thrust Washers in Modern Machinery Design." Mechanical Systems and Signal Processing, 170, 108818.